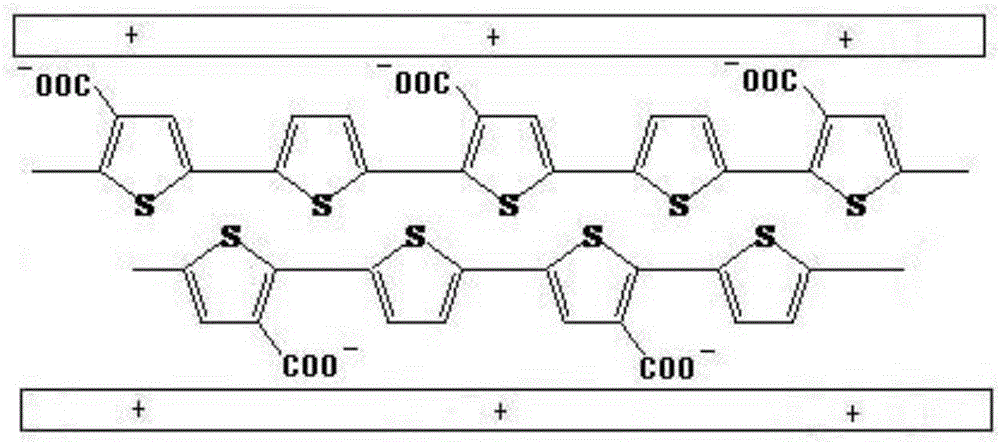

Poly 3-carboxylic thiophene/thiophene intercalation hydrotalcite composite material and preparation technology thereof

A composite material and preparation technology, which is applied in the field of poly-3-carboxythiophene/thiophene intercalated hydrotalcite composite material and its preparation, to achieve the effects of environmental protection and non-toxic materials, simple preparation process and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

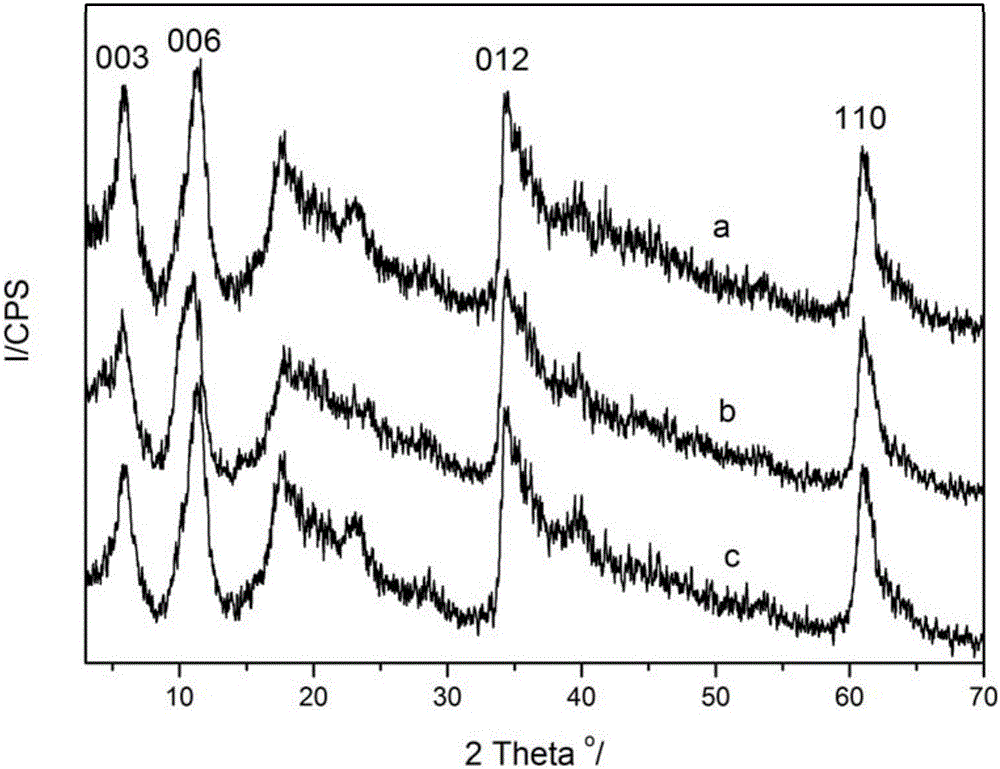

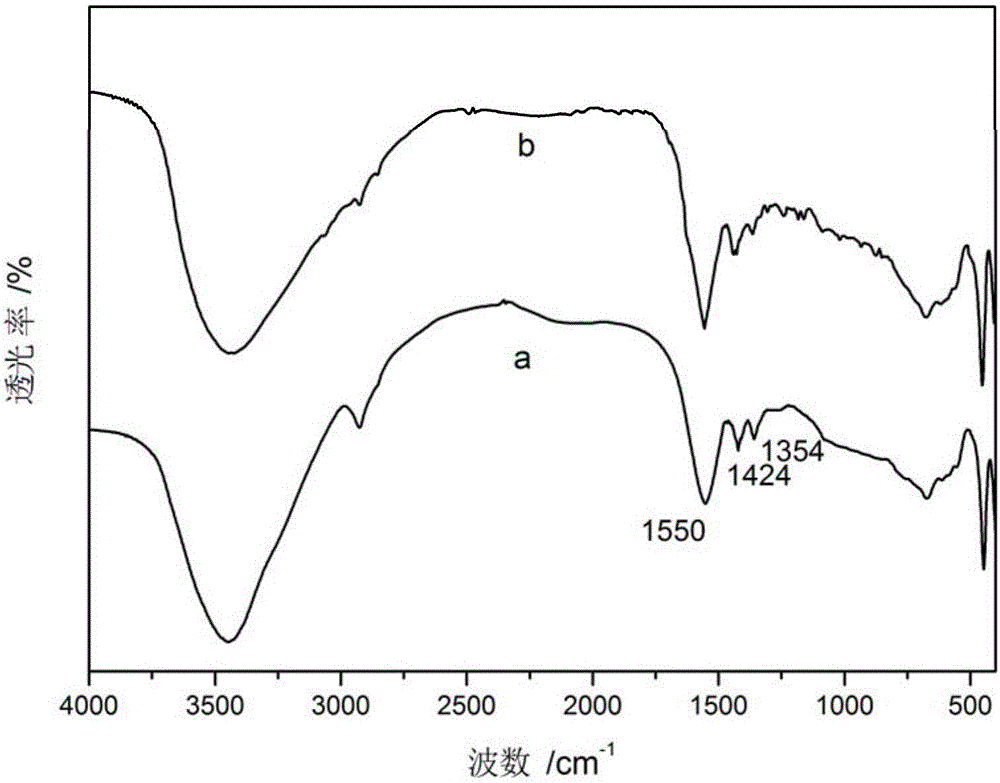

Embodiment 1

[0042] The preparation process of poly-3-carboxythiophene / thiophene intercalated hydrotalcite composite material, the steps are as follows:

[0043] (1) Weigh 17.8g Zn(NO 3 ) 2 ·6H 2 O and 11.3g Al (NO 3 ) 3 ·9H 2 O dissolved in 100mL to remove CO 2 The mixed salt solution was prepared in deionized water, and 5.6g of NaOH was weighed and dissolved in 50mL to remove CO. 2 deionized water, at room temperature N 2 Under the protection, the mixed salt solution and the NaOH solution were added to the four-necked flask by the double-drop method, and then the pH value was adjusted to 7 with 0.1 mol / L NaOH solution, and the obtained slurry was crystallized at 60 ° C for 72 h, The product was placed in a centrifuge, centrifuged at 2500 r / min for 5 min, and then used to remove CO. 2 The deionized water was washed until the washing solution was neutral, and the characterization was performed after drying at 50 °C for 48 h to obtain the hydrotalcite precursor ZnAl-NO 3 -LDHs, whe...

Embodiment 2

[0052] The preparation process of poly-3-carboxythiophene / thiophene intercalated hydrotalcite composite material, the steps are as follows:

[0053] (1) Weigh 15.4g Mg(NO 3 ) 2 ·6H 2 O and 11.3g Al (NO 3 ) 3 ·9H 2 O dissolved in 100mL to remove CO 2 The mixed salt solution was prepared in deionized water, and 5.6g of NaOH was weighed and dissolved in 50mL to remove CO. 2 deionized water, at room temperature N 2 Under the protection, the mixed salt solution and NaOH solution were added into the four-necked flask by the double-drop method and vigorously stirred, and then the pH value was adjusted to 10 with 5.0 mol / L NaOH solution, and the obtained slurry was crystallized at 90 °C for 12 h. The product was put into a centrifuge, centrifuged at 3500 r / min for 3 min, and then used to remove CO. 2 The deionized water was washed until the washing solution was neutral, and the characterization was performed after drying at 90 °C for 20 h to obtain the hydrotalcite precursor M...

Embodiment 3

[0062] The preparation process of poly-3-carboxythiophene / thiophene intercalated hydrotalcite composite material, the steps are as follows:

[0063] (1) Weigh 26.7g Zn(NO 3 ) 2 ·6H 2 O and 11.3g Al (NO 3 ) 3 ·9H 2 O dissolved in 100mL to remove CO 2 The mixed salt solution was prepared in the deionized water of 2 of deionized water at room temperature N 2 Under the protection, the mixed salt solution and NaOH solution were added into a four-necked flask by the double-drop method, and then the pH value was adjusted to 7 with 1.0 mol / L NaOH solution, and the obtained slurry was crystallized at 70 ° C for 48 h, The product was placed in a centrifuge, centrifuged at 3000 r / min for 4 min, and then used to remove CO. 2 The deionized water was washed until the washing solution was neutral, and the characterization was performed after drying at 70 °C for 36 h to obtain the hydrotalcite precursor ZnAl-NO 3 -LDHs, where Zn 2+ with Al 3+ The molar ratio is 3;

[0064] (2) Wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com