Stain-resistant water-based paint composition

A technology of water-based paint and composition, applied in the field of anti-fouling coating and anti-fouling water-based paint composition, which can solve the problems of more pores, poor coating compactness, and deterioration of anti-fouling property.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

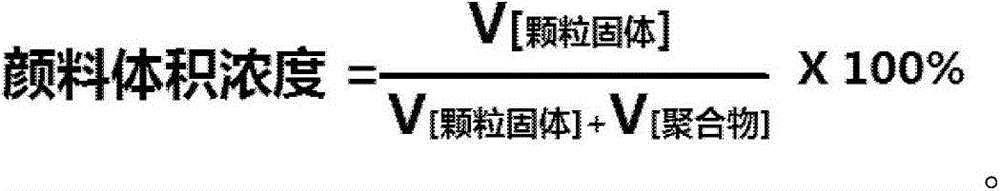

[0023] The present invention provides a stain-resistant aqueous coating composition comprising: one or more aqueous latexes containing self-crosslinkable polymer particles; and one or more particulate solids, wherein the polymer particles having a Tg of 10°C or less, and the particulate solid comprises a combination of tabular particulate solids and spherical particulate solids, wherein the weight ratio of the tabular particulate solids to the spherical particulate solids is 1:1 or greater; And wherein the aqueous coating composition has a pigment volume concentration (PVC) of 45% or higher, and the aqueous coating composition is substantially free of volatile organic compounds. Preferably, the aqueous coating composition has a pigment volume concentration of 50% or higher.

[0024]As used herein, "aqueous latex" refers to a stable dispersion of a synthetic resin (ie polymer) in particulate form in an aqueous liquid medium, optionally with the aid of a suitable dispersing aid ...

Embodiment 1-2

[0125] The aqueous coating compositions of Examples 1-2 were prepared as follows.

[0126] Under stirring at a low speed of 350-450rpm / min, add 180g or 200g of deionized water and a certain amount of thickener Plus 330, wetting agent Tritox X-100, dispersant P30, defoamer SN154, Sodium carbonate in water, and stir for 5-10 minutes so that it is homogeneous. Then add granular solid rutile titanium dioxide R706, ground calcium carbonate GF-168, talc powder TA-800, and mica powder to the mixture, and stir at a high speed of 80-1250rpm / min for 20-30 minutes to form a uniform slurry. Finally, under medium-speed stirring at 500-700rpm / min, add mineral oil defoamer CF246, fluorine-containing additive FS 81, silicone resin emulsion BS 45, and optional high-boiling film-forming additive Colsoal to the homogeneous slurry 290, polyacrylic acid emulsion SF 506, CM1P5 bactericide, W350 fungicide, alkali swelling thickener TT935 and the remaining part of deionized water until uniform, ther...

Embodiment 3

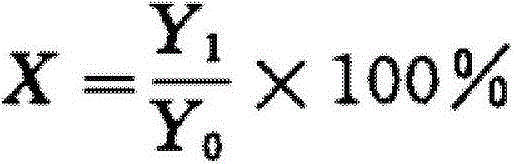

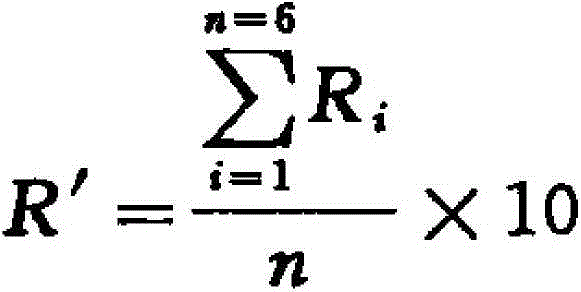

[0133] In order to more clearly show the resistance of the water-based coating composition of the present invention to water-based stains and oily stains, Table 3 below summarizes the stain resistance of the water-based coating composition of Example 1 corresponding to different stains.

[0134] Table 3: Resistance of the stain-resistant aqueous coating composition of Example 1 to different stains

[0135]

[0136] As can be seen from the results of the above table 3, the water-based coating composition of the present invention has good tolerance to water-based stains and oil-soluble stains,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com