Crust breaking agent and application thereof

A shell breaking agent and shell breaking technology, applied in the application, organic fertilizer, fertilizer mixture and other directions, can solve the problems of increased pollution, economic loss, reduction, etc., and achieve the effect of easy operation and control of environmental conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

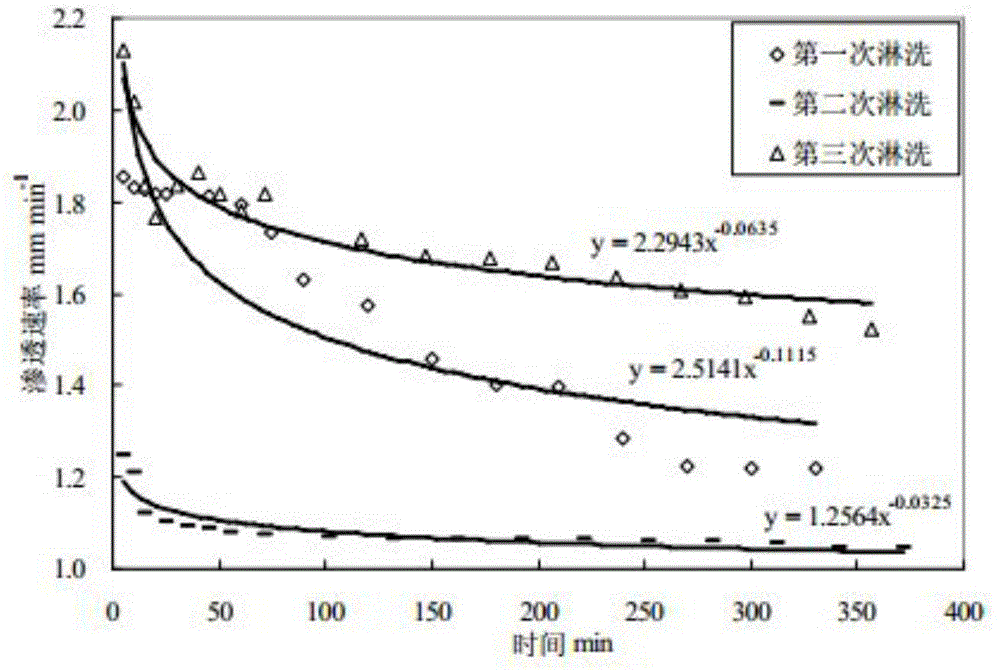

[0029] The experimental site is located in the Shenyang Ecological Station of the Chinese Academy of Sciences. The method of artificially filling the soil column is used for the infiltration experiment. The soil is collected from Bali Town, Haicheng City. Physical and chemical properties of the tested soil: pH 8.36, organic matter 6.7g / kg, total magnesium content 18.07g / kg, clay 39.2%, silt 41.6%, gravel 19.3%, water-soluble magnesium 33.53%, water-soluble calcium 25.86 %, exchanged magnesium 1.77%, exchanged calcium 1.29%. The collected soil was air-dried indoors, and after a week, it was ground with a mortar to make it pass through a 2mm sieve for later use.

[0030] Application of soil amendments:

[0031] Control group: weigh 505g of spare soil and put it into a plexiglass column with an inner diameter of 5cm as a control, and the filling height is about 25cm, so that the soil bulk density is about 1.15g cm -3 .

[0032] Test group: Weigh 400g of soil and place it in a ...

Embodiment 2

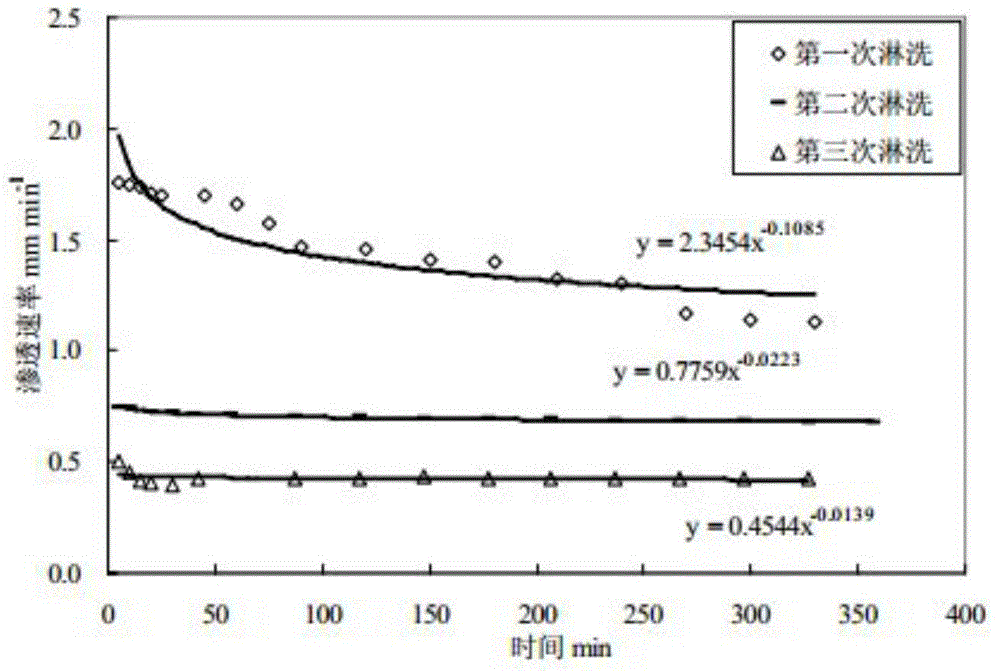

[0039] The physical and chemical properties of the tested soil and the filling of the soil column are the same as in Example 1, except that:

[0040] Test group: Weigh 400g of soil and put it in the soil column, sprinkle 100g of soil, 5g of magnesium oxide powder, and 4g of calcium dihydrogen phosphate on the surface of the soil column, mix evenly, and sprinkle on the surface of the soil in the soil column. The conditions of the infiltration experiment and the method of alternating wet and dry are the same as in Example 1. The initial penetration rate at the first rinse is 0.61mmmin -1 , although the initial permeation velocity in the second rinse is 1.11mm min -1, after two wet and dry cycles, the initial penetration rate of the third rinse is 1.09mm min -1 . By comparing the results, the penetration rate is slightly increased. Along with carrying out alternately between wet and dry, calcium dihydrogen phosphate accelerates and decomposes the effect of crust to show gradu...

Embodiment 3

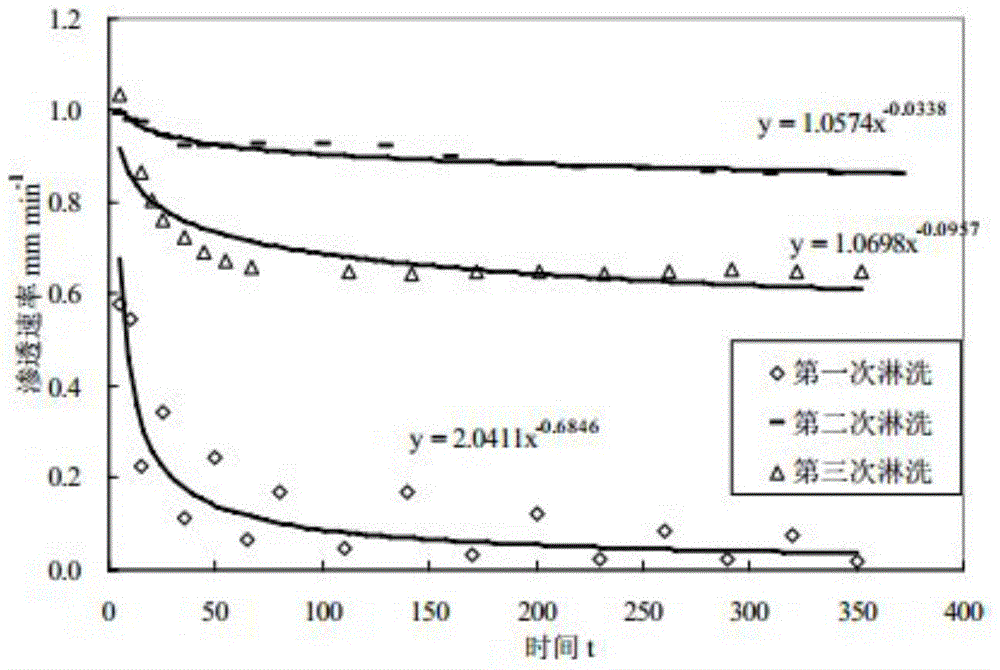

[0042] The physical and chemical properties of the tested soil and the filling of the soil column are the same as in Example 1, except that:

[0043] Test group: Weigh 400g of soil and put it in the soil column, sprinkle 100g of soil, 5g of magnesium oxide powder, and 5g of calcium dihydrogen phosphate on the surface of the soil column, mix evenly, and sprinkle on the surface of the soil in the soil column. The conditions of the infiltration experiment and the method of alternating wet and dry are the same as in Example 1. By washing three times and alternating wet and dry twice, the permeation rate increases by 22% compared to Example 1 ( Figure 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com