Technology for extracting torreya grandis seed oil by aqueous process

A technology of Chinese torreya seed and water agent method, which is applied in the field of fine processing and comprehensive utilization of agricultural products, can solve the problems of organic solvent residue, high production cost, and low oil yield, and achieve no solvent residue, high oil quality, and high oil yield. The effect of nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: single factor experimental screening

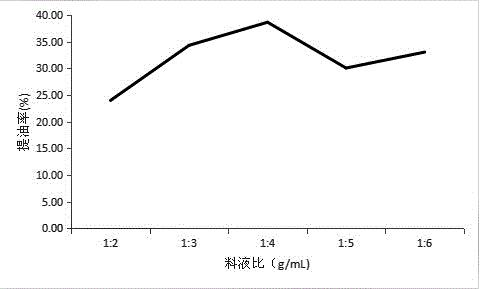

[0031] 1. Effect of liquid-material ratio on oil extraction rate: at 60°C, pH 7, leaching time 30min, the ratio of solid-liquid is 1:2, 1:3, 1:4, 1:5, 1:6, respectively. The effect of different solid-liquid ratios on the extraction rate, the results are shown in figure 1 . Depend on figure 1 It can be seen that the optimum liquid-to-material ratio is 1:3-1:5g / mL.

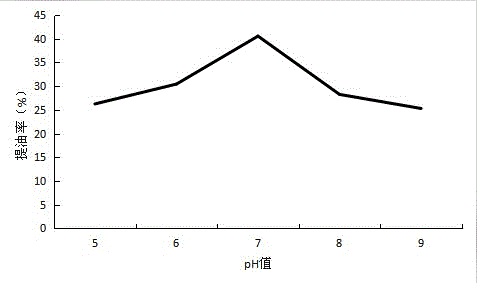

[0032] 2. Effect of feed liquid pH on oil extraction rate: at a material-liquid ratio of 1:3, 60°C, leaching time of 30 minutes, adjust the pH to 5, 6, 7, 8, and 9 respectively, and compare the effects of different pH on oil extraction rate impact, see figure 2 . Depend on figure 2 It can be seen that the more suitable pH value is 6-8.

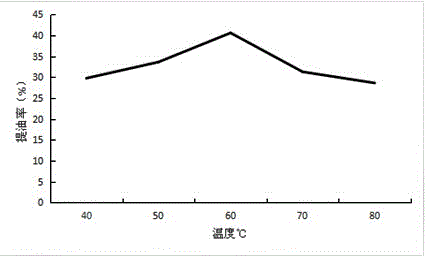

[0033] 3. Effect of extraction temperature on oil extraction rate: at pH 7, extraction time is 30 minutes, material-water ratio is 1:3, see the results image 3 . have image 3 It can be seen that the best tempe...

Embodiment 2

[0035] Example 2: Orthogonal Process Optimization of Torreya Torreya Seed Oil Extraction Conditions

[0036] 1. Orthogonal experiment

[0037] On the basis of the single factor test, the four factors of material-water ratio, slurry pH, extraction time, and extraction temperature were selected, and the oil extraction rate was used as an index to conduct an orthogonal experiment. 9 (3 4 ) Orthogonal experiment to optimize the process conditions of Torreya seed oil extraction by aqueous method.

[0038] Table 1 Orthogonal test factors and levels

[0039] factor

pH

extraction time

extraction temperature

1

1:3

6

20

50

2

1:4

7

30

60

3

1:5

8

40

70

[0040] Table 2 Orthogonal experiment results of optimization of extraction conditions of Chinese torreya seed oil

[0041]

[0042] From the range R values in Table 2, it can be concluded that the influencing factors on the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com