Detachable hydraulic cylinder with carbon fiber composite for connection and load bearing

A composite material and carbon fiber technology, applied in cylinders, fluid pressure actuators, engine components, etc., can solve the problems of high maintenance cost of composite hydraulic cylinders, high quality of all-metal hydraulic cylinders, and weakened load-bearing structures, etc., to improve equipment Economical, maintaining structural integrity, and improving dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

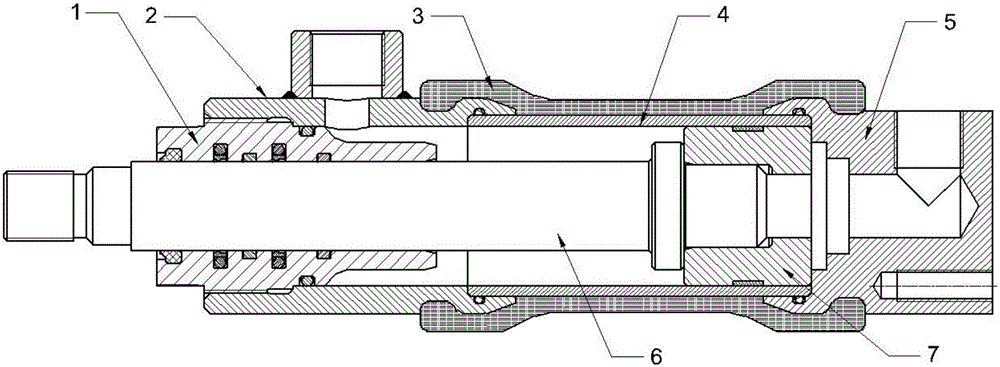

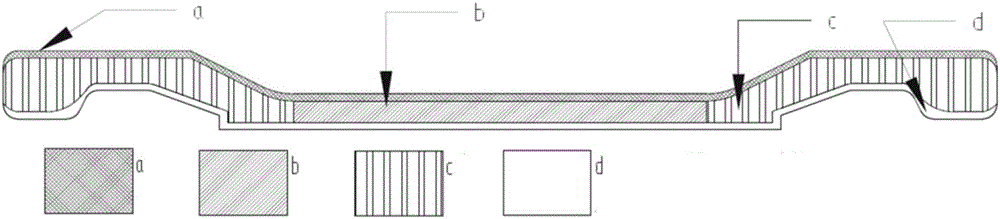

[0024] Such as figure 1 As shown, the detachable hydraulic cylinder provided by the present invention is connected and carried by carbon fiber composite material is basically the same structure as the traditional hydraulic cylinder, except that the outer layer of the cylinder is made of 3-series composite material, and the sealing ring, dustproof ring, support ring, Guide rings are selected in accordance with the national standard, except for the corresponding standard parts, and other parts are made of No. 45 steel. The hydraulic cylinder of the present invention comprises an end cover 1, a cylinder head 2, a cylinder outer layer 3, a cylinder liner 4, a cylinder bottom 5, a piston rod 6 and a piston 7; the cylinder head 2, the cylinder bottom 5, the cylinder liner 4 The three constitute the metal part of the cylinder assembly; the outer layer 3 of the cylinder uses ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com