Acoustic surface wave sensor manufacturing method based on nano imprinting technology

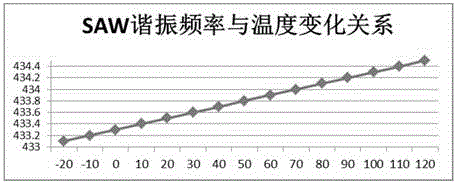

A technology of nanoimprinting and surface acoustic wave, which is applied in the field of nanoimprinting, can solve the problems of narrow frequency response range, difficult to control precision consistency, high insertion loss, etc., and achieve low production cost, high practicability, improved consistency and The effect of quality factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

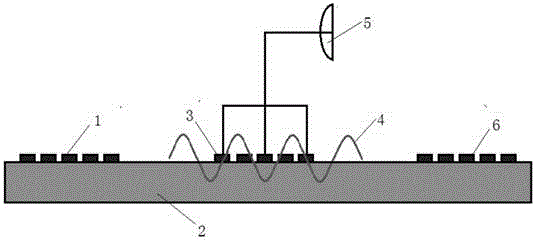

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0025] Nanoimprint technology is an emerging cross-technology combining nanomaterials and printing technology. Using the latest nano-functional sensing materials, through nano-printing methods, and using processes such as evaporation and spin-coating temperature treatment, it can be printed on substrates such as ceramics, plastics, and rubber. Printing electronic circuits and devices does not require complicated etching process, and has the characteristics of simple process and no pollution.

[0026] The technology was first proposed in 1995 by Stephen Chou, a Chinese professor at Princeton University in the United States. By placing the nanostructure template on the surface of the polymer film, under certain conditions s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com