Mechanical pressure equipment process flow control method and integrated machine control device

A technology of mechanical pressure and process flow, applied in presses, program control, program control in sequence/logic controllers, etc., can solve problems such as the inability to meet equipment intelligence, increase machine tool control accuracy, improve work efficiency, Effects without human intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

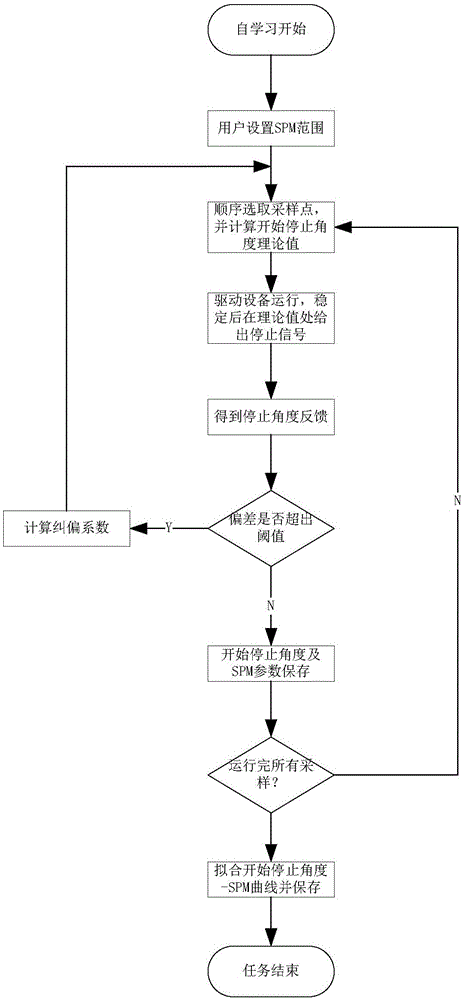

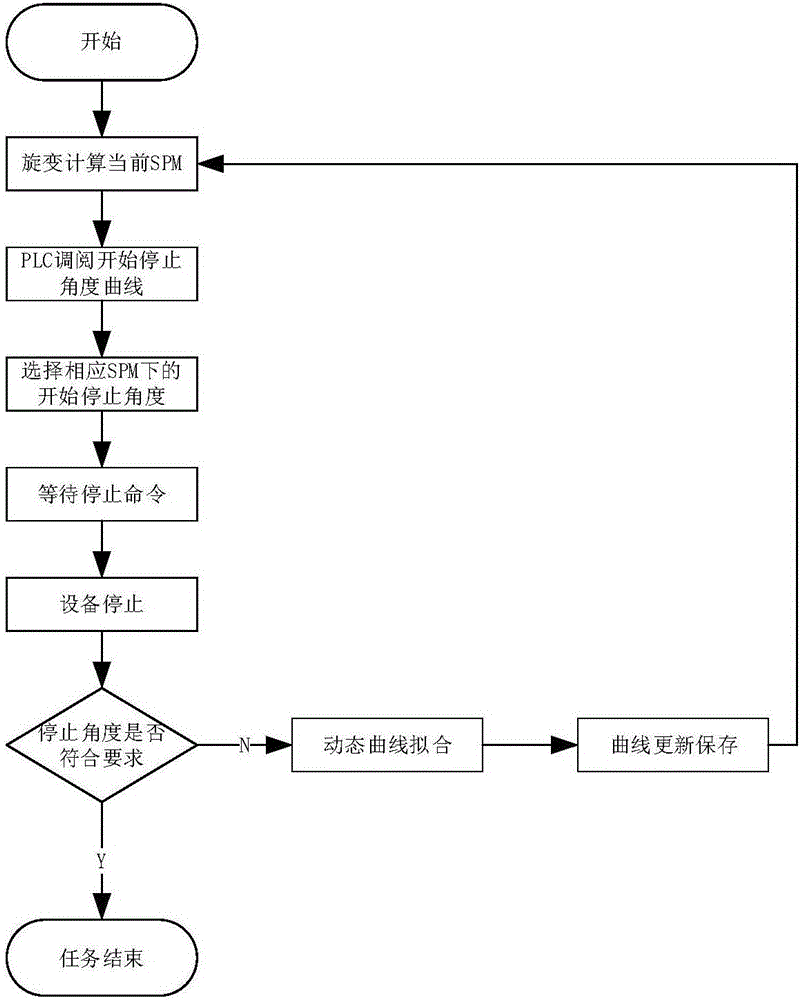

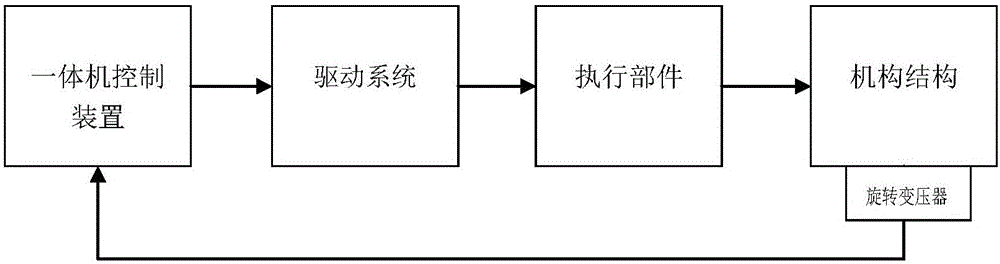

[0045] The content involved in the present invention is mainly aimed at the controller device of the electrical control part of the mechanical pressure industry, and aims at the technical update of the traditional controller device and the improvement of the industry process, so as to improve the efficiency of the mechanical pressure equipment and reduce the cost. The present invention proposes a fully automatic and intelligent process flow control method for mechanical pressure equipment, that is, the self-learning of the start and stop angles. In the process of machine factory debugging, the relevant mode is turned on to carry out the self-learning of the start and stop angles to obtain the initial start and stop angles. Fitting curves and corresponding calculation formulas; and further provide a dynamic update method for starting and stopping angles during operation, and dynamically adjust the calculation of starting and stopping angles according to the actual stopping angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com