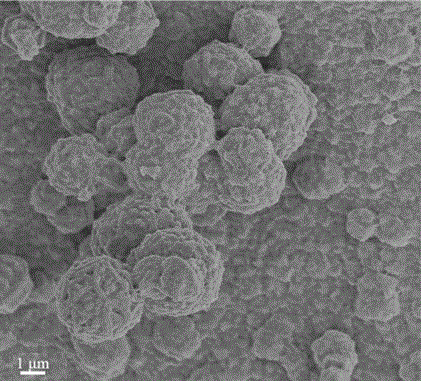

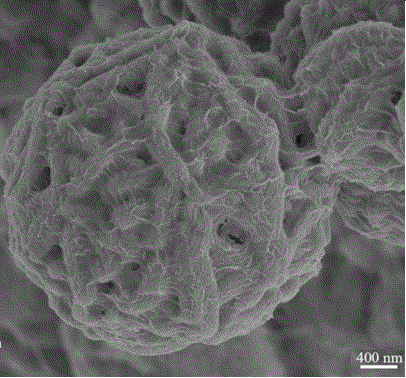

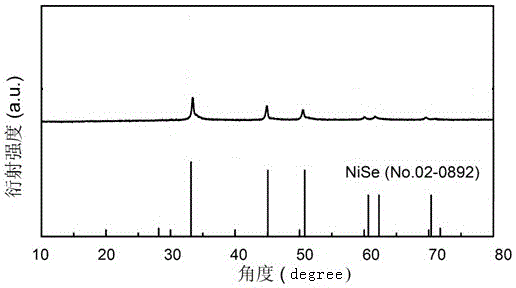

NiSe porous nanosphere material used for super capacitor and preparation method thereof

A technology of supercapacitors and nanospheres, applied in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of less research and application of supercapacitors, and achieve favorable migration and diffusion, high specific capacitance and conductivity. , the effect of high electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve the raw materials 1mmol nickel acetate tetrahydrate and 1mmol sodium selenite in 20mL deionized water, stir evenly at room temperature and place in a reaction kettle, then add a mixture of concentrated ammonia water and diethylenetriamine (5mL concentrated ammonia water, 15mL diethylenetriamine), then immerse the substrate into the solution in the reactor, and then place the reactor in an oven for hydrothermal synthesis reaction, the reaction temperature is 180 ° C, the reaction time is 14 hours, and cooled to room temperature , washed and dried to obtain the final product NiSe porous nanosphere material.

Embodiment 2

[0031] Dissolve the raw materials 1mmol nickel acetate tetrahydrate and 1mmol sodium selenite in 20mL deionized water, stir evenly at room temperature and place in a reaction kettle, then add a mixture of concentrated ammonia water and diethylenetriamine (5mL concentrated ammonia water, 15mL diethylenetriamine), then immerse the substrate into the solution in the reactor, and then place the reactor in an oven for hydrothermal synthesis reaction, the reaction temperature is 180°C, the reaction time is 8 hours, and cooled to room temperature , washed and dried to obtain the final product NiSe porous nanosphere material.

Embodiment 3

[0033] Dissolve the raw materials 1mmol nickel acetate tetrahydrate and 1mmol sodium selenite in 20mL deionized water, stir evenly at room temperature and place in a reaction kettle, then add a mixture of concentrated ammonia water and diethylenetriamine (5mL concentrated ammonia water, 15mL diethylenetriamine ethylenetriamine), then immerse the substrate into the solution in the reactor, and then place the reactor in an oven for hydrothermal synthesis reaction, the reaction temperature is 180 ° C, the reaction time is 10 hours, cooled to room temperature, washed Dry to obtain the final product NiSe porous nanosphere material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com