Catalytic electrode of proton exchange membrane fuel cell, battery provided with same and preparation method thereof

A proton exchange membrane, fuel cell technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve the problems of battery output power decline, battery performance decline, fuel cell application limitations, etc., to achieve long service life, use Efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

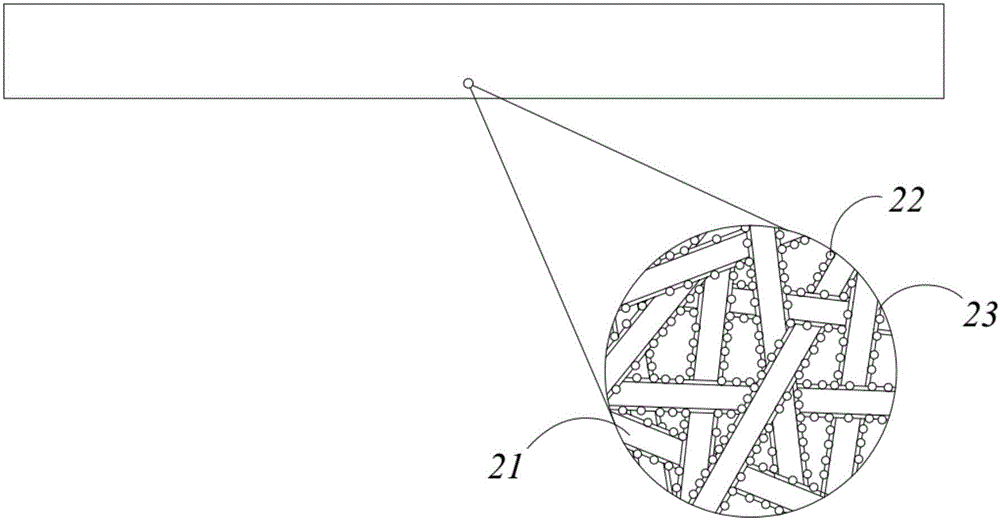

[0033] Such as figure 1 The catalytic electrode of a proton exchange membrane fuel cell shown includes a conductive support layer in a network structure, a proton conductive monomer 23 and a catalyst 22 located on the surface of the conductive support layer and inside the network structure, and the conductive support layer The thickness is 1 to 10 μm. The conductive carrier layer is formed by mixing multi-walled carbon nanotubes and carbon nanofibers 21, so that its interior presents a porous structure, and its porosity is adjusted to 80-90%, and its specific surface area is 50-200m 2 / g. On the outer walls of the multi-walled carbon nanotubes and carbon nanofibers 21 (that is, on the surface of the conductive support layer and inside the pores), the catalyst 22 and the proton-conducting monomer 23 are supported; the catalyst 22 is either Pt particles or Pt alloy p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com