A denitrification ammonia gas pretreatment system

A pretreatment, ammonia technology, applied in the field of denitrification ammonia pretreatment system, can solve problems such as safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

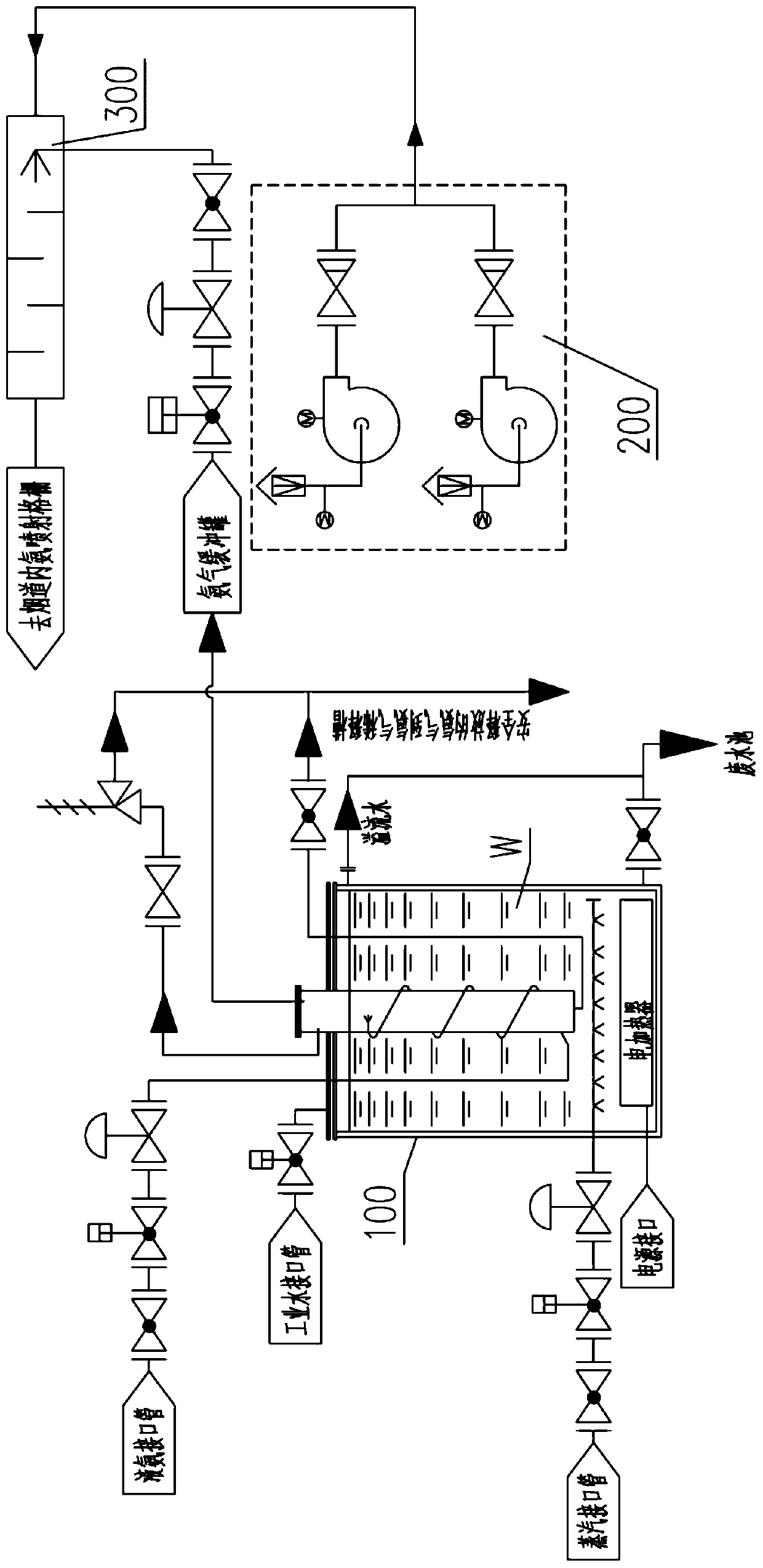

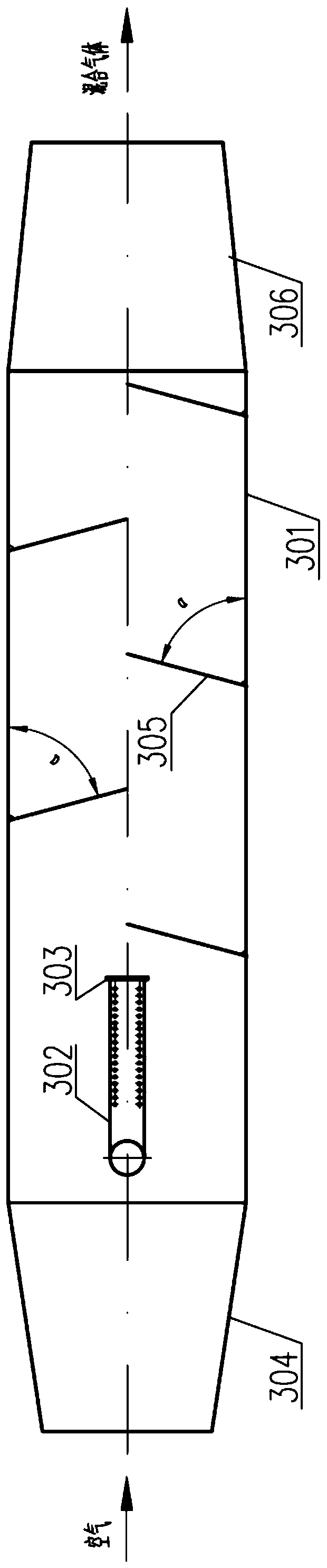

[0034] Such as figure 1 Said, in one embodiment, a kind of denitrification ammonia pretreatment system is provided, comprising: liquid ammonia evaporation device 100, ammonia air mixing device 300, dilution air supply device 200 that provides system air to ammonia air mixing device, As shown in the figure, it is generally one or more sets of dilution fans.

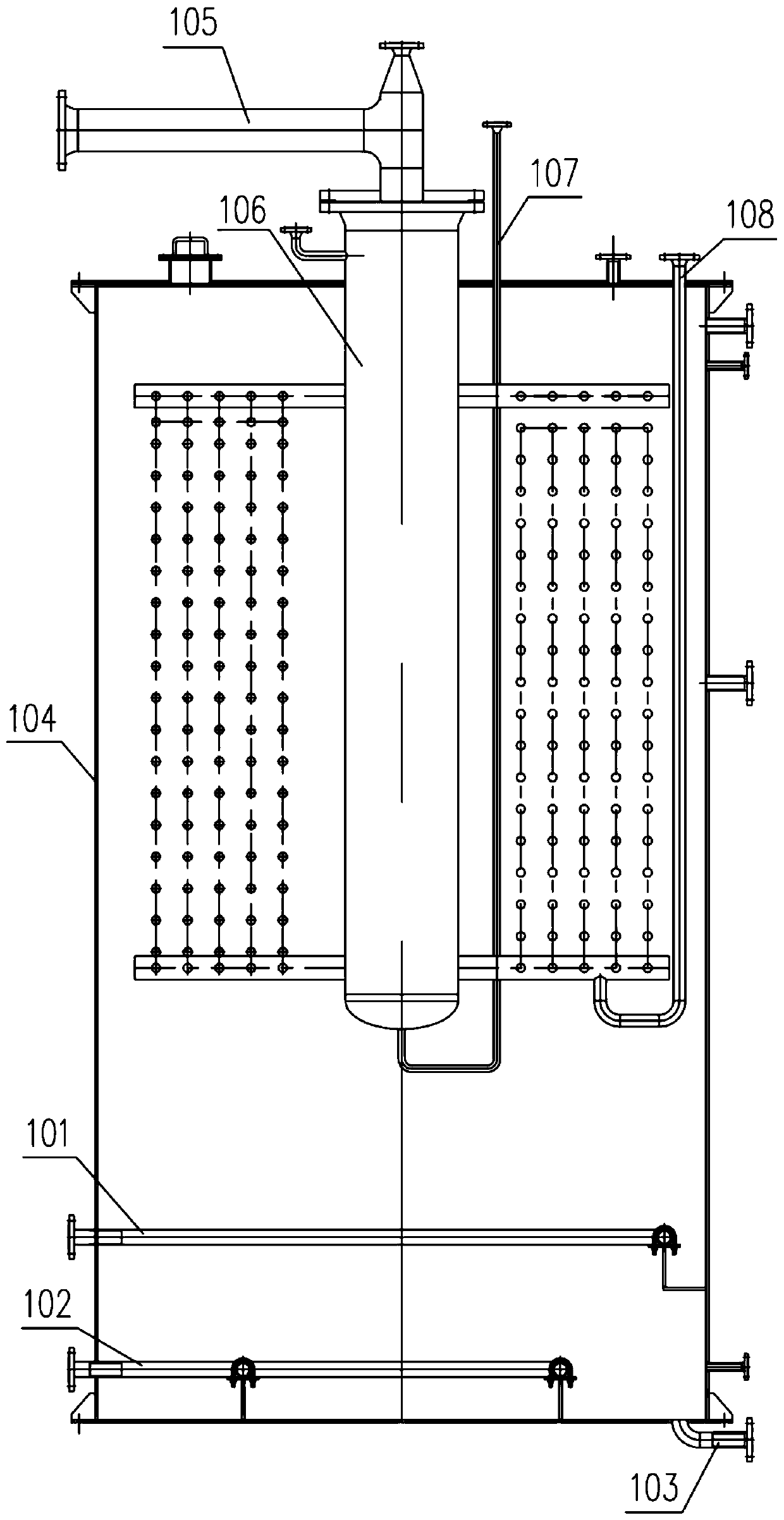

[0035] to combine figure 1 and figure 2 As shown, the liquid ammonia evaporating device 100 includes: an evaporator body 104 having a cavity containing medium W (generally warm water); a liquid ammonia heat exchanger 108 arranged in the evaporator body 104; a liquid ammonia heat exchanger 108 One end is connected with the liquid ammonia inlet, and the other end is connected with an ammonia gas collection device 106 arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com