Yttrium tantalate high temperature ceramic and preparation method thereof

A technology of high-temperature ceramics and yttrium tantalate, which is applied in the field of preparation of yttrium tantalate high-temperature ceramics and yttrium tantalate high-temperature ceramics, can solve problems affecting performance, etc., and achieve the effects of low preparation cost, good stability, and good ferroelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

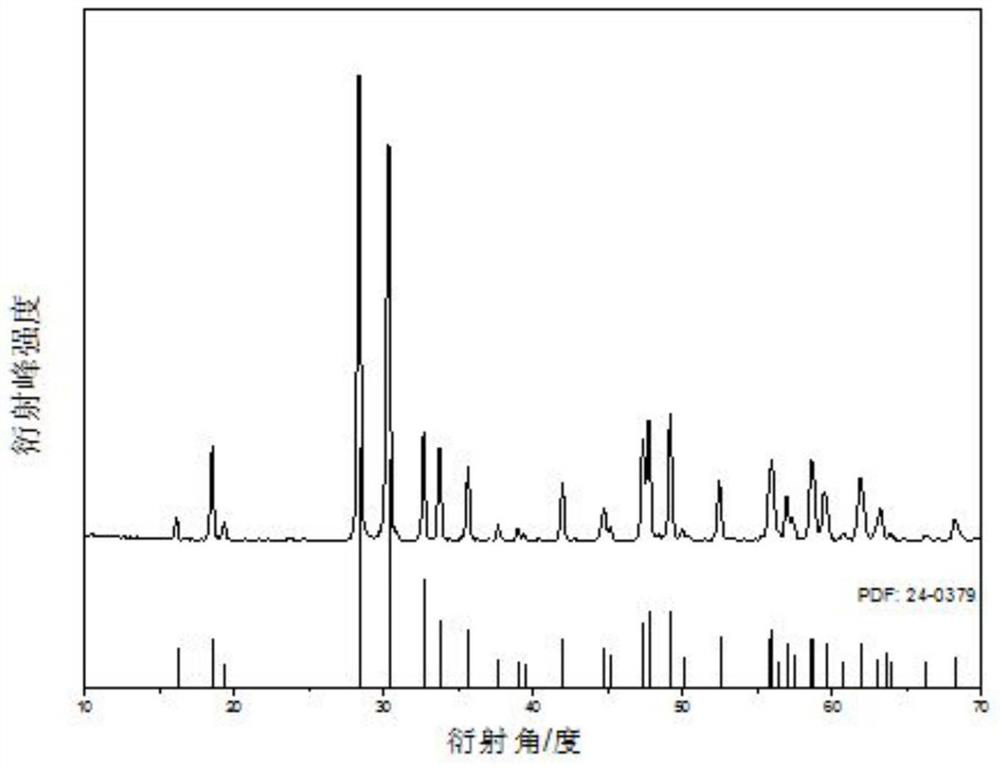

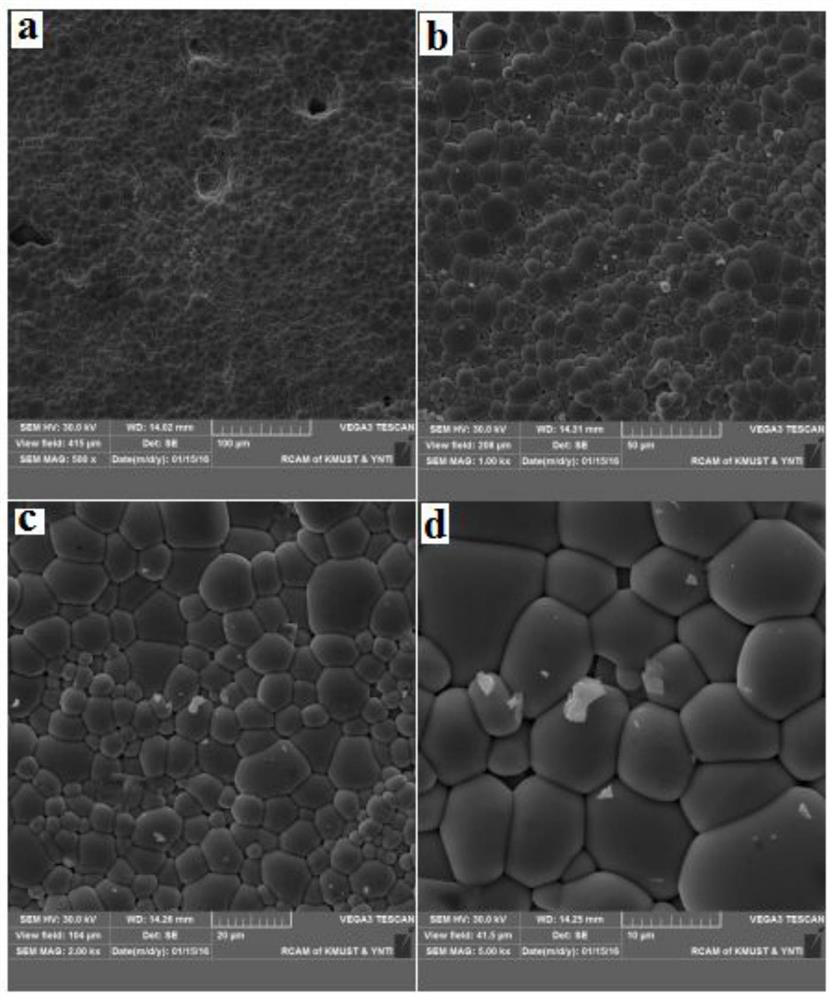

[0032] A new type of high temperature resistance, anti-oxidation, anti-wear yttrium tantalate (YTaO) described in this embodiment 4 ) ceramic material and preparation method thereof, specifically comprising the following steps:

[0033] Weigh 8.0611g of yttrium oxide and 15.7749g of tantalum oxide, mix them in absolute ethanol, place them in a planetary ball mill (the speed of the ball mill is 300, and the milling time is 180min), and dry the milled solution at 60°C After 24 hours, pass through a 100-mesh sieve, and then use a mold to press into shape (holding pressure is 8MPa, holding time is 60min). After pressing, it is pre-fired at 1100°C for 5 hours.

[0034] After calcining the raw material for the first time, the mixture is ground evenly, dissolved in absolute ethanol again, and placed in a planetary ball mill for ball milling (the rotating speed of the ball mill is 300r / min, and the ball milling time is 180min), and the solution that is ball milled is placed in the pla...

Embodiment 2

[0036] A new type of high temperature resistance, anti-oxidation, anti-wear yttrium tantalate (YTaO) described in this embodiment 4 ) ceramic material and preparation method thereof, specifically comprising the following steps:

[0037] Weigh 8.0611g of yttrium oxide and 15.7749g of tantalum oxide, mix them in absolute ethanol, place them in a planetary ball mill for ball milling (the speed of the ball mill is 500r / min, and the ball milling time is 60min), and the milled solution is heated at 80°C After drying for 10 hours, pass through a 300-mesh sieve, and then use a mold to press and form (holding pressure is 12MPa, holding time is 30min), after pressing and forming, it is pre-fired at 800°C for 10 hours.

[0038] After calcining the raw material for the first time, the mixture is ground evenly, dissolved in absolute ethanol again, and placed in a planetary ball mill for ball milling (the rotating speed of the ball mill is 500r / min, and the ball milling time is 60min), and ...

Embodiment 3

[0041] A new type of high temperature resistance, anti-oxidation, anti-wear yttrium tantalate (YTaO) described in this embodiment 4 ) ceramic material and preparation method thereof, specifically comprising the following steps:

[0042] Specifically include the following steps:

[0043] Weigh 8.0611g of yttrium oxide and 15.7749g of tantalum oxide, mix them in absolute ethanol, place them in a planetary ball mill for ball milling (the speed of the ball mill is 400r / min, and the ball milling time is 120min), and the milled solution is heated at 70°C After drying for 16 hours, pass through a 200-mesh sieve, and then use a mold to press and form (the holding pressure is 9MPa, and the holding time is 40min). After pressing and forming, it is pre-fired at 900°C for 9 hours.

[0044] After calcining the raw material for the first time, the mixed material is ground evenly, dissolved in absolute ethanol again, placed in a planetary ball mill for ball milling (the rotating speed of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com