Positive and negative electrode plates and positive and negative electrode plate covering structure during winding for improving safety of power battery

A technology of positive and negative electrodes and power batteries, which is applied to non-aqueous electrolyte battery electrodes, secondary batteries, structural parts, etc., can solve problems such as insufficient consideration of safety issues, thermal runaway of batteries, and large extrusion force, etc., to achieve Reduce the probability of battery short circuit, reduce safety risks, and alleviate the effect of extrusion pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

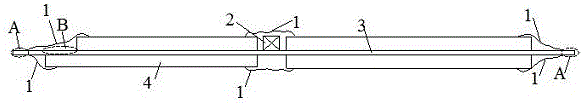

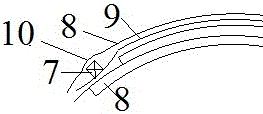

[0014] A section of empty foil is left at the head, middle and tail of the positive electrode sheet, the head adopts a dislocation coating method, and the middle and tail adopts an aligned coating method, wherein the coating lines of the head and tail are covered with adhesive paper. In the middle position, the empty foil is welded to the positive electrode ear, and the double-sided adhesive paper is applied to cover the coating line area on both sides; the width of the misaligned area B of the positive electrode sheet coating is 5~15mm, and the adhesive paper covering all the coating lines covers the active material by 1~3mm. Leave 1~2mm empty foil area after sticking the adhesive paper on the tail.

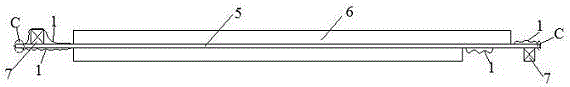

[0015] The negative electrode sheet adopts a bipolar lug structure, and a section of empty foil is left at the head and tail of the negative electrode sheet for welding the negative electrode lugs. The head adopts an aligned coating method, and the tail adopts a misplaced coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com