Method of continuous vacuum freezing and drying of instant tea powder

A vacuum freeze-drying and instant tea powder technology, applied in the direction of tea, application, food science, etc., can solve the problems of the influence of flavor active ingredients, the inability of continuous production, the large influence of flavor quality, etc., to control re-infection, low cost, The effect of high recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

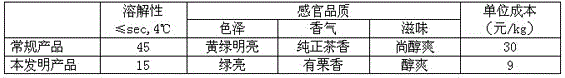

[0022] Embodiment 1: instant green tea powder

[0023] 1) Take 60kg of roasted green tea and 60kg of roasted green tea and blend them, put them into a far-infrared aroma extractor and refire at a temperature of 110°C for 4 minutes, cool and pulverize them and pass through a 20-mesh sieve;

[0024] 2) Put the tea treated in step 1) into a multi-stage countercurrent column for low-temperature extraction, the tea-water ratio is 1:6, the extraction temperature is 45°C, and the extraction time is 40 minutes. The obtained tea extract is filtered through a 200-mesh stainless steel filter;

[0025] 3) Cool the tea extract obtained in step 2) to 10°C, pass through a 0.2um membrane after being centrifuged in a disc centrifuge, the centrifugal speed is 6000rpm, and the membrane filtration temperature is 25°C;

[0026] 4) Concentrate the concentrated solution obtained in step 3) through a DT disc tube reverse osmosis membrane to a final concentrated solution of 20Brix, with a concentratio...

Embodiment 2

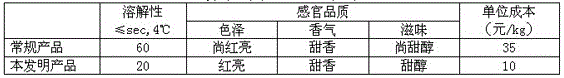

[0030] Embodiment 2: instant black tea powder

[0031] 1) Blend 100kg Assam CTC and 20kg Souchong black tea, put it into a far-infrared aroma enhancing machine and refire at a temperature of 90°C for 15 minutes, cool and crush it and pass it through a 40-mesh sieve;

[0032] 2) Put the tea treated in step 1) into a multi-stage countercurrent column for low-temperature extraction, the tea-water ratio is 1:10, the extraction temperature is 52°C, and the extraction time is 45 minutes. The obtained tea extract is filtered through a 300-mesh stainless steel filter;

[0033] 3) Cool the tea extract obtained in step 2) to 8°C, pass through a 0.2um membrane after being centrifuged in a disc centrifuge, the centrifugal speed is 5000rpm, and the membrane filtration temperature is 15°C;

[0034] 4) Concentrate the concentrated solution obtained in step 3) through the DT disc tube reverse osmosis membrane to the final concentrated solution 18Brix, the concentration temperature is 30°C, an...

Embodiment 3

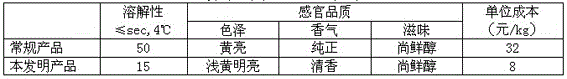

[0038] Embodiment 3: instant oolong tea powder

[0039] 1) Blend 110kg of Tieguanyin tea and 10kg of roasted green tea, put it into a far-infrared aroma enhancing machine and refire at a temperature of 105°C for 10 minutes, cool and crush it and pass it through a 10-mesh sieve;

[0040] 2) Put the tea treated in step 1) into a multi-stage countercurrent column for low-temperature extraction, the tea-water ratio is 1:20, the extraction temperature is 70°C, and the extraction time is 15 minutes. The tea extract obtained is filtered with a 60-mesh stainless steel filter;

[0041] 3) Cool the tea extract obtained in step 2) to 20°C, pass through a 0.3um membrane after being centrifuged in a disc centrifuge, the centrifugal speed is 4500rpm, and the membrane filtration temperature is 35°C;

[0042] 4) Concentrate the concentrated solution obtained in step 3) through the DT disc tube reverse osmosis membrane to the final concentrated solution 22Brix, the concentration temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com