Method for preparing fine maca powder

A technology of maca powder and fine powder, which is applied in the field of preparation of maca fine powder, can solve the problems of not being able to label maca ingredients, etc., and achieve the effect of saving raw materials and energy, fully and efficiently utilizing, and having the same content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

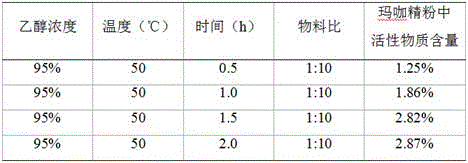

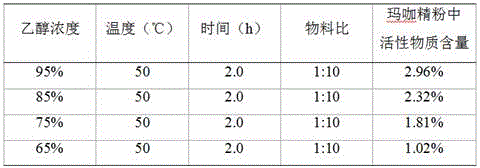

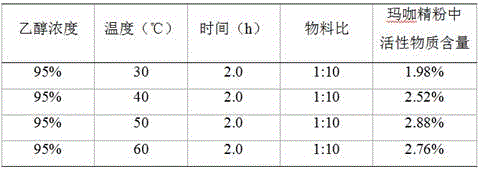

Method used

Image

Examples

Embodiment 1

[0021] a. Crushing: Wash the fresh maca roots, dry them naturally for 2 days, cut them into slices with a thickness of 0.3 cm, and then dry them at 50°C until the maca dry product has a moisture content of 6%, and then place them in multi- Pulverize in the function pulverizer, make the particle size of maca powder be 200 orders;

[0022] b, extraction: put the maca powder of step a into the multifunctional extraction tank, then add edible ethanol with a concentration of 95v / v% to the extraction tank according to the solid-to-liquid ratio kg:L, and seal the extraction tank , reflux extraction at a temperature of 55°C for 90 minutes;

[0023] c, centrifugation: the Maca extract obtained in step b is centrifuged through a centrifuge, the filtrate is taken, the filter residue is repeatedly extracted once, and the obtained filtrate is combined twice;

[0024] d. Evaporation: put the combined filtrate in a low-temperature concentrator, evaporate under reduced pressure at a temperat...

Embodiment 2

[0027] a. Crushing: Wash the fresh maca roots, dry them naturally for 2 days, cut them into slices with a thickness of 0.2 cm, and then dry them at 50°C until the maca dry product has a moisture content of 5%, and then place them in multi- Pulverize in the function pulverizer, make the particle size of maca powder be 100 orders;

[0028] b, extraction: put the maca powder of step a into the multifunctional extraction tank, then add edible ethanol with a concentration of 65v / v% to the extraction tank according to the solid-liquid ratio kg:L, and seal the extraction tank , reflux extraction at a temperature of 40°C for 120 minutes;

[0029] c, centrifugation: the Maca extract obtained in step b is centrifuged through a centrifuge, the filtrate is taken, the filter residue is repeatedly extracted once, and the obtained filtrate is combined twice;

[0030] d. Evaporation: place the combined filtrate in a low-temperature concentrator, evaporate under reduced pressure at a temperat...

Embodiment 3

[0033] a. Crushing: Wash the fresh maca roots, dry them naturally for 2 days, cut them into slices with a thickness of 0.5 cm, and then dry them at 50°C until the maca dry product has a moisture content of 9%, and then place them in multi- Pulverize in the function pulverizer, make the particle size of maca powder be 300 orders;

[0034] b. Extraction: put the maca powder in step a into the multifunctional extraction tank, then add edible ethanol with a concentration of 85v / v% to the extraction tank according to the solid-to-liquid ratio kg:L as 1:15, and seal the extraction tank , reflux extraction at a temperature of 60°C for 30 minutes;

[0035] c, centrifugation: the maca extract obtained in step b is centrifuged through a centrifuge, the filtrate is taken, the filter residue is repeatedly extracted once, and the obtained filtrate is combined twice;

[0036] d. Evaporation: put the combined filtrate in a low-temperature concentrator, evaporate under reduced pressure at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com