Amoxicillin soluble powder and preparation method thereof

A technology of amoxicillin and amoxicillin trihydrate, applied in the field of amoxicillin soluble powder and its preparation, can solve the problems of amoxicillin failure, easy ring opening, etc. The effect of easy operation of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

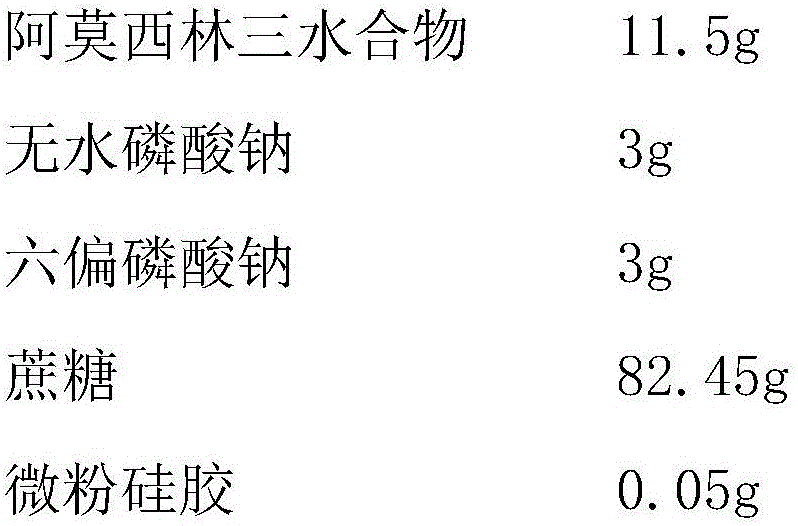

[0033] The amoxicillin soluble powder of the present embodiment, its prescription composition and preparation process are as follows:

[0034]

[0035] (1) The raw material amoxicillin trihydrate is micronized, and jet milling is used to obtain drug particles with a particle diameter of 50-100 microns.

[0036] (2) Grinding and sieving anhydrous sodium phosphate, sodium hexametaphosphate, sucrose, and micronized silica gel, with a mesh number of 80-100 mesh.

[0037] (3) Mixing: Mix the materials obtained in (1) and (2), the mixing time is 40 minutes, mix well and set aside.

[0038] (4) Subpackage: Subpackage and inspect the materials obtained in (3) to obtain the finished product of amoxicillin soluble powder.

Embodiment 2

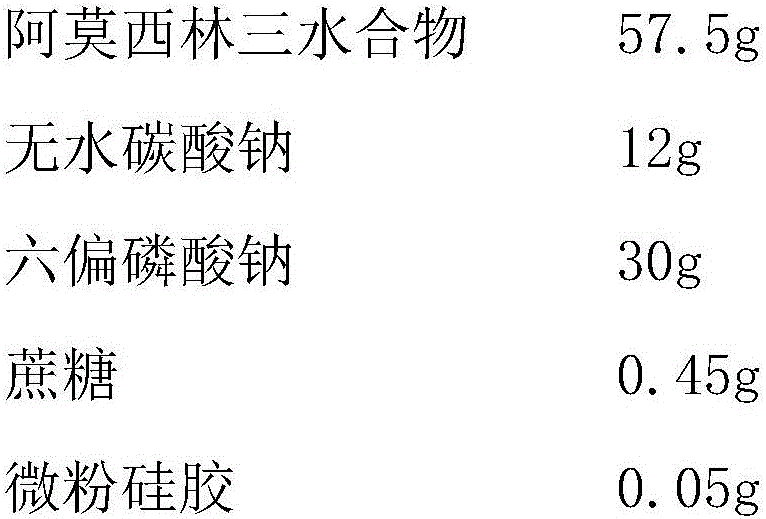

[0040] The amoxicillin soluble powder of the present embodiment, its prescription composition and preparation process are as follows:

[0041]

[0042] (1) The raw material amoxicillin trihydrate is micronized, and jet milling is used to obtain drug particles with a particle diameter of 50-100 microns.

[0043] (2) Grinding and sieving anhydrous sodium carbonate, sodium hexametaphosphate, sucrose, and micropowder silica gel, the mesh number of which is 80-100 mesh.

[0044] (3) Mixing: Mix the materials obtained in (1) and (2), the mixing time is 40 minutes, mix well and set aside.

[0045] (4) Subpackage: Subpackage and inspect the materials obtained in (3) to obtain the finished product of amoxicillin soluble powder.

Embodiment 3

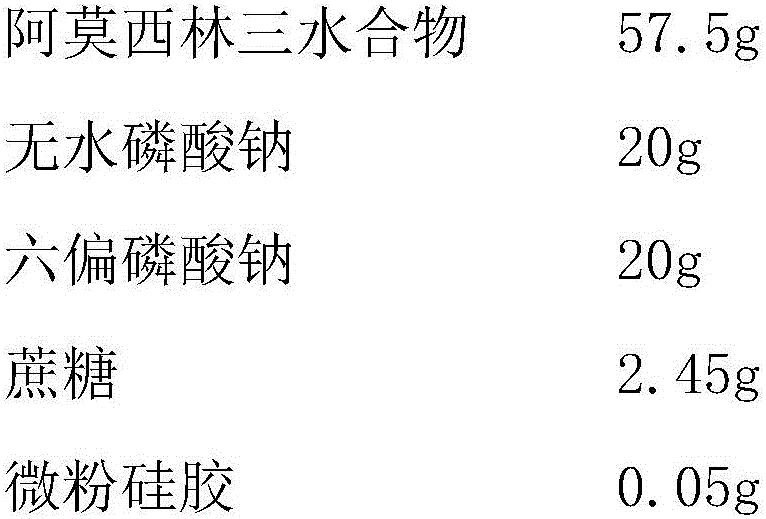

[0047] The amoxicillin soluble powder of the present embodiment, its prescription composition and preparation process are as follows:

[0048]

[0049] (1) The raw material amoxicillin trihydrate is micronized, and jet milling is used to obtain drug particles with a particle diameter of 50-100 microns.

[0050] (2) Grinding and sieving anhydrous sodium phosphate, sodium hexametaphosphate, sucrose, and micronized silica gel, with a mesh number of 80-100 mesh.

[0051] (3) Mixing: Mix the materials obtained in (1) and (2), the mixing time is 40 minutes, mix well and set aside.

[0052] (4) Subpackage: Subpackage and inspect the materials obtained in (3) to obtain the finished product of amoxicillin soluble powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com