Extraction and purification process for total phenolic acid in chaenomeles speciosa

A technology of wrinkled papaya and total phenolic acids, which is applied to medical preparations containing active ingredients, plant raw materials, plant/algae/fungus/moss components, etc., can solve the problems of low extraction efficiency and waste of total phenolic acids, Achieve the effects of high production efficiency, good extraction rate and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

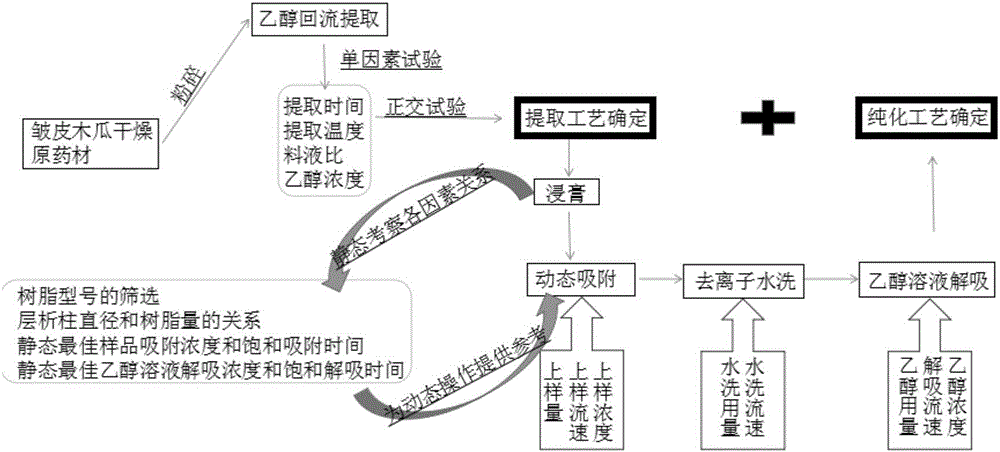

[0020] The method of extraction and purification provided in this embodiment is as figure 1 As shown, in this embodiment, the selection of various process parameters and the selection of resin types have been repeatedly tested in order to obtain the best technical conditions.

[0021] 1) The main characteristics of the macroporous resin used in the experiment

[0022] According to the polarity and other physical parameters of the macroporous resin, the following six types of resins, D101, AB-8, NKA-9, S-8, HPD750, D1400, were screened for pretreatment.

[0023] 2) Static adsorption and desorption test of resin

[0024] Weigh the above-mentioned types of resins respectively, put them in conical flasks, add a certain concentration of phenolic acid extract deionized water solution, seal with a parafilm, place in a constant temperature oscillator, 25 ° C, 120r / min, shake for 24h, After reaching the adsorption equilibrium, filter the filtrate to determine the concentration of phe...

Embodiment 2

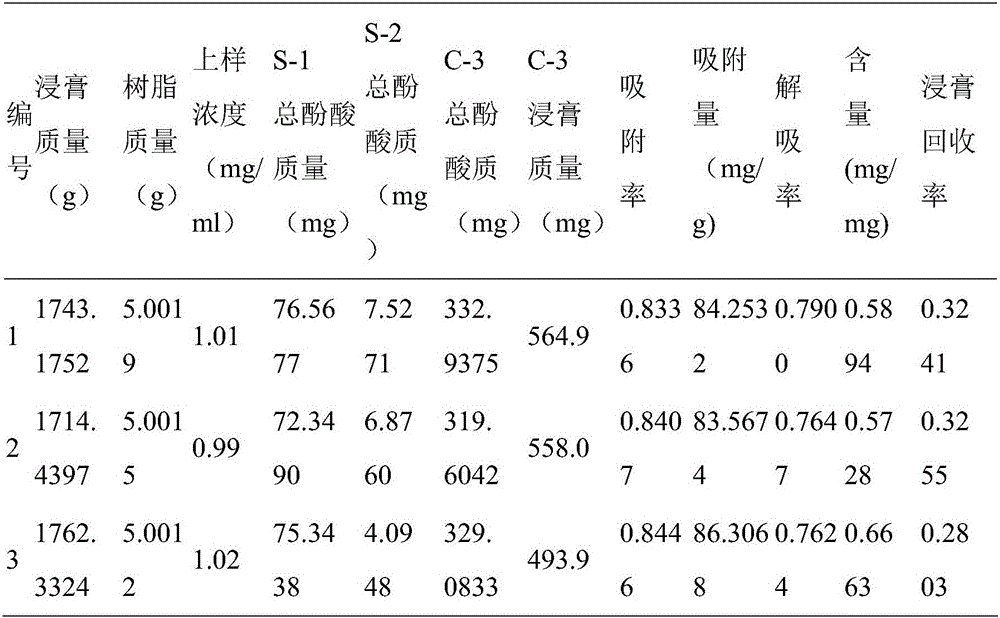

[0058] Take about 5g of D101 macroporous resin, pack it into a column, wash it with alcohol and wash it with water until there is no alcohol smell, apply the aqueous solution of wrinkled papaya extract with a concentration of approximately 1.0mg / ml, the flow rate of the sample is 2BV / h, and the sample volume is 20BV, and the effluent is collected S-1, deionized water elution, elution flow rate 2BV / h, dosage 4BV, collected effluent S-2, 60% ethanol solution elution, elution flow rate 4BV / h, dosage 4BV, collected effluent C-3 , respectively measure the phenolic acid concentration of the three effluents to obtain the quality of the effluent C-3. Repeat this experiment three times to obtain the adsorption rate and elution rate, as well as the content of total phenolic acids in papaya wrinkled skin after purification. The conclusions are shown in the table below.

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com