Arsenic-poisoned denitration catalyst regeneration liquid and application

A denitration catalyst, arsenic poisoning technology, applied in catalyst regeneration/reactivation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. Denitration requirements and other issues, to avoid multiple roasting, meet the requirements of denitration engineering, reduce the effect of safety impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

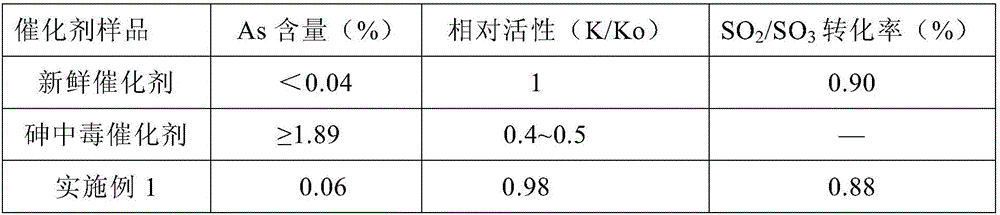

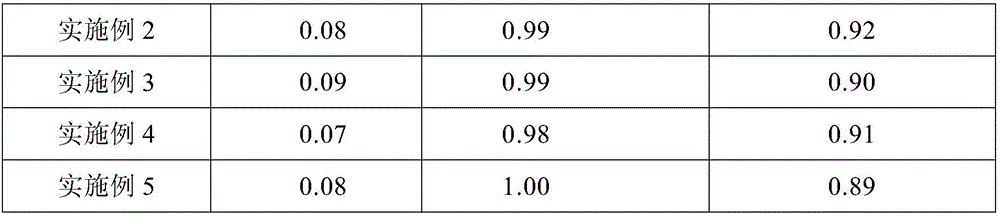

Examples

Embodiment 1

[0014] 1. Preparation of regeneration solution

[0015] 1. Preparation of cleaning solution

[0016] In the cleaning tank, the penetrant SF with a mass fraction of 1%, H 2 o 2 The mass fraction is 0.05%, the rest is water, and the pH value of the solution is adjusted to 10.5 by using TMAH. Carry out air bubbling treatment for 20 minutes, make it mix uniformly, leave to age for 1 hour, and obtain cleaning liquid, totally 7000L.

[0017] 2. Preparation of active replenishing liquid

[0018] In the activation pool, configure VOSO with a molar concentration of 0.8mol / L 4 , and the rest is water. Air stirring was carried out for 10 minutes to make it evenly mixed, and left to age for 1 hour to obtain an active replenishing solution, totaling 7000 L.

[0019] 2. Denitrification catalyst regeneration process

[0020] Put the arsenic poisoning catalyst module into the cleaning tank with cleaning solution, keep it at 60°C, and wash it with air bubbling for 60 minutes; then, imme...

Embodiment 2

[0022] 1. Preparation of regeneration solution

[0023] 1. Preparation of cleaning solution

[0024] In the cleaning pool, configure the mass fraction of penetrant SF as 1%, H 2 o 2 The mass fraction is 0.03%, the rest is water, and the pH value of the solution is adjusted to 10.5 by using TMAH. Carry out air bubbling treatment for 20 minutes, make it mix uniformly, leave to age for 1 hour, and obtain cleaning liquid, totally 7000L.

[0025] 2. Preparation of active replenishing liquid

[0026] In the activation pool, configure VOSO with a molar concentration of 0.6mol / L 4 , and the rest is water, and the air is stirred for 10 minutes to make it evenly mixed, left to age for 1 hour, and the active replenishing liquid is obtained, a total of 7000L.

[0027] 2. Denitrification catalyst regeneration process

[0028] Put the arsenic poisoning catalyst module into the cleaning pool with cleaning solution, keep it at 50°C, and wash it with air bubbling for 50 minutes; then, im...

Embodiment 3

[0030] 1. Preparation of regeneration solution

[0031] 1. Preparation of cleaning solution

[0032] In the cleaning pool, configure the mass fraction of penetrant SF as 1%, H 2 o 2 The mass fraction is 0.05%, the rest is water, and the pH value of the solution is adjusted to 10.5 by using TMAH. Carry out air bubbling treatment for 20 minutes, make it mix uniformly, leave to age for 1 hour, and obtain cleaning liquid, totally 7000L.

[0033] 2. Preparation of active replenishing liquid

[0034] In the activation pool, configure VOSO with a molar concentration of 0.4mol / L 4 , and the rest is water. Air stirring was carried out for 10 minutes to make it evenly mixed, and left to age for 1 hour to obtain an active replenishing solution, totaling 7000 L.

[0035] 2. Denitrification catalyst regeneration process

[0036] Put the arsenic poisoning catalyst module into the cleaning pool with cleaning solution, keep it at 45°C, and wash it with air bubbling for 55 minutes; then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com