Implementation method for electric dust removal of high-frequency high-voltage SIR power supply

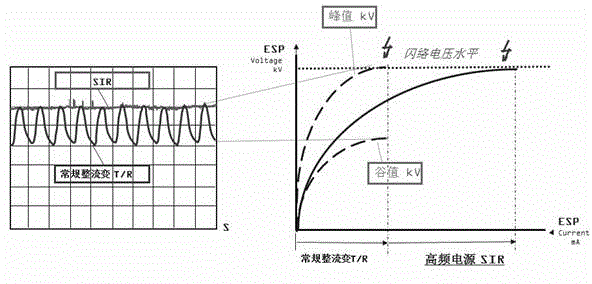

A realization method, high-frequency and high-voltage technology, applied in the fields of environmental protection and electric dust removal, can solve problems such as low corona voltage, large output ripple, and increased infrastructure costs, so as to increase power supply voltage and current, reduce dust emission concentration, Effect of reducing dust emission concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

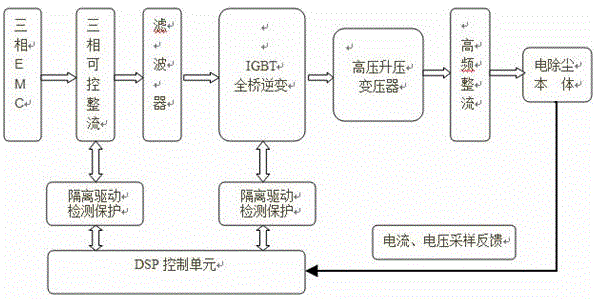

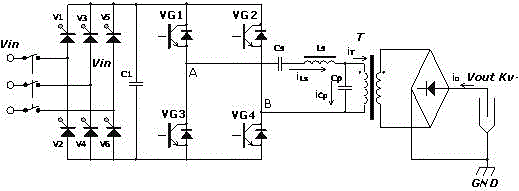

Method used

Image

Examples

Embodiment 1

[0027] A steel factory 360m 2 16 high-frequency power supplies are used for all electric fields of the dust collector to replace the original power frequency power supply. The original power frequency power supply, the secondary voltage is about 40kV, the average monthly electricity consumption is 890,000 kW, and the monthly electricity bill is about 547,000 yuan. After applying this high-frequency power supply, the secondary voltage increases to above 60kV, and there is basically no flashover. The average monthly electricity consumption is 510,000 kW, the monthly electricity bill is about 313,000 yuan, and the electricity cost is saved by 234,000 yuan. The power saving efficiency is about 42.6%. At the same time, the emission concentration is changed from 48.5mg / Nm before transformation 3 Reduced to 31.5mg / Nm after emission modification 3 .

Embodiment 2

[0029] A company in Yunnan owns a power plant to improve the efficiency of the 3# electrostatic precipitator, and replace the original power frequency power supply with 8 high-frequency power supplies. Power consumption before transformation: 310kW / h Power consumption after transformation: 143kW / h Power saving efficiency: 54%. At the same time, the emission concentration is changed from 200mg / Nm before transformation 3 Reduced to 45mg / Nm after emission modification 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com