A broad-spectrum chlorine-free coagulation accelerator accelerator for oil field cementing

A technology of accelerating coagulation early strength and early strength agent, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problem of slow development of cement stone strength, long thickening transition time and initial and final setting transition time, and unfavorable oil and gas. Water channeling and other problems, to achieve the effect of shortening the initial setting time and initial and final setting transition time, shortening the thickening time and thickening transition time, and shortening the strength development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a broad-spectrum chlorine-free coagulation accelerator accelerator for cement used in oilfield well cementing, which is prepared by the following steps:

[0039] Weigh 1 part by weight of sodium fluorosilicate, 1 part by weight of calcium aluminate, 1 part by weight of aluminum sulfate, and 1 part by weight of metakaolin, and pour them into a mixing device and mix them uniformly to obtain the early strength agent.

[0040] This embodiment also provides a kind of cement slurry that is used for oil field well cementing, and it is prepared through the following steps:

[0041] Take by weighing 700g grade G oilfield cement, 21g early strength agent (accounting for 3.0% of cement mass), 17.5g fluid loss reducer DRF-300S, 4.2g dispersant DRS-1S and 301g water, the above components Mix to make cement slurry.

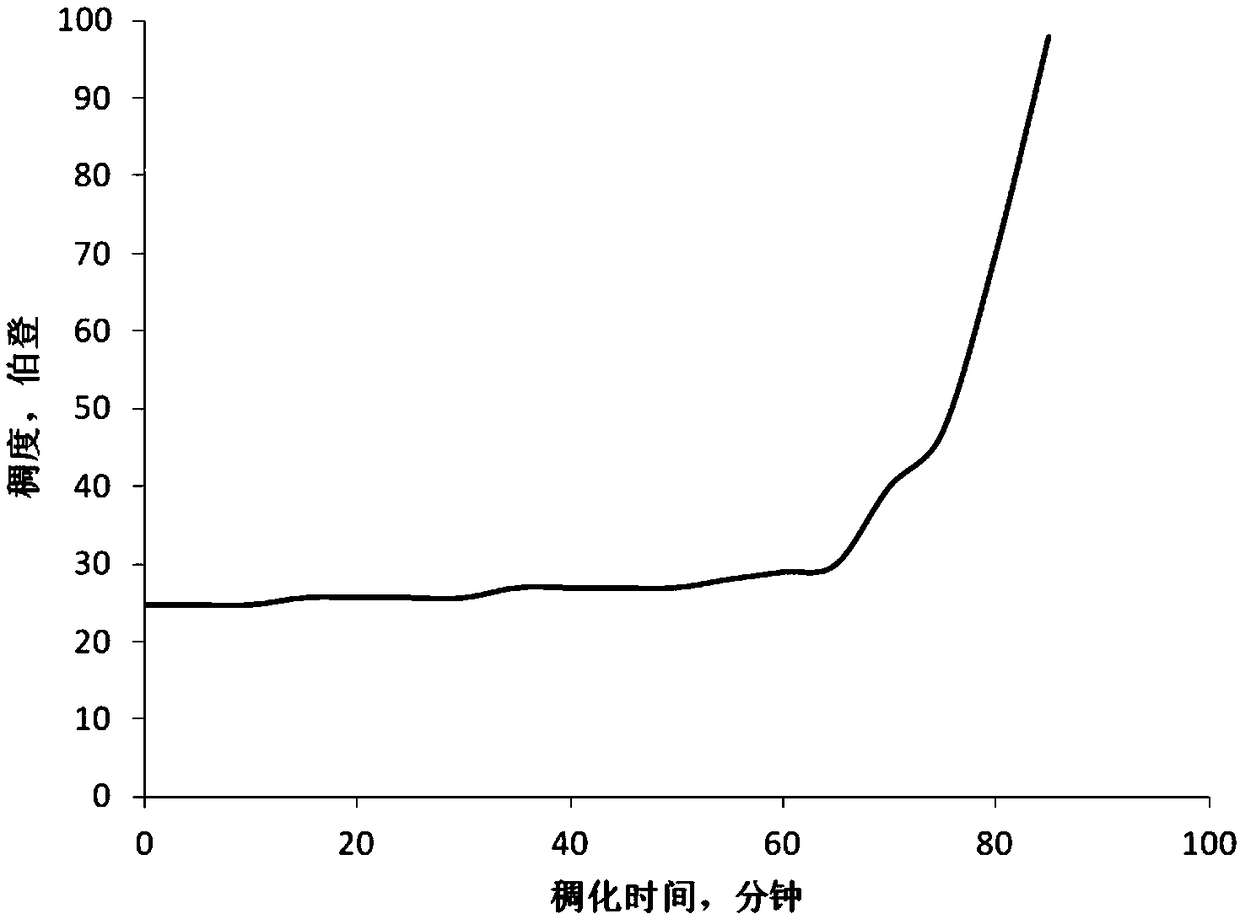

[0042] The measured performance parameters of the cement slurry are shown in Table 1. figure 1 When being the 3% of cement quality for embodim...

Embodiment 2

[0045] This embodiment provides a broad-spectrum chlorine-free coagulation accelerator accelerator for cement used in oilfield well cementing, which is prepared by the following steps:

[0046] Weigh respectively 1.5 parts by weight of sodium aluminate, 1.5 parts by weight of calcium formate, 1 part by weight of aluminum silicate, and 1 part by weight of magnesium oxide, and pour them into a mixing device in turn and mix them uniformly to obtain the early strength agent.

[0047] This embodiment also provides a kind of cement slurry that is used for oil field well cementing, and it is prepared through the following steps:

[0048] Take by weighing 700g grade G oilfield cement, 21g early strength agent (accounting for cement mass ratio 3.0%), 17.5g fluid loss reducer DRF-300S, 4.2g dispersant DRS-1S and 301g water, the above components Mix to make cement slurry.

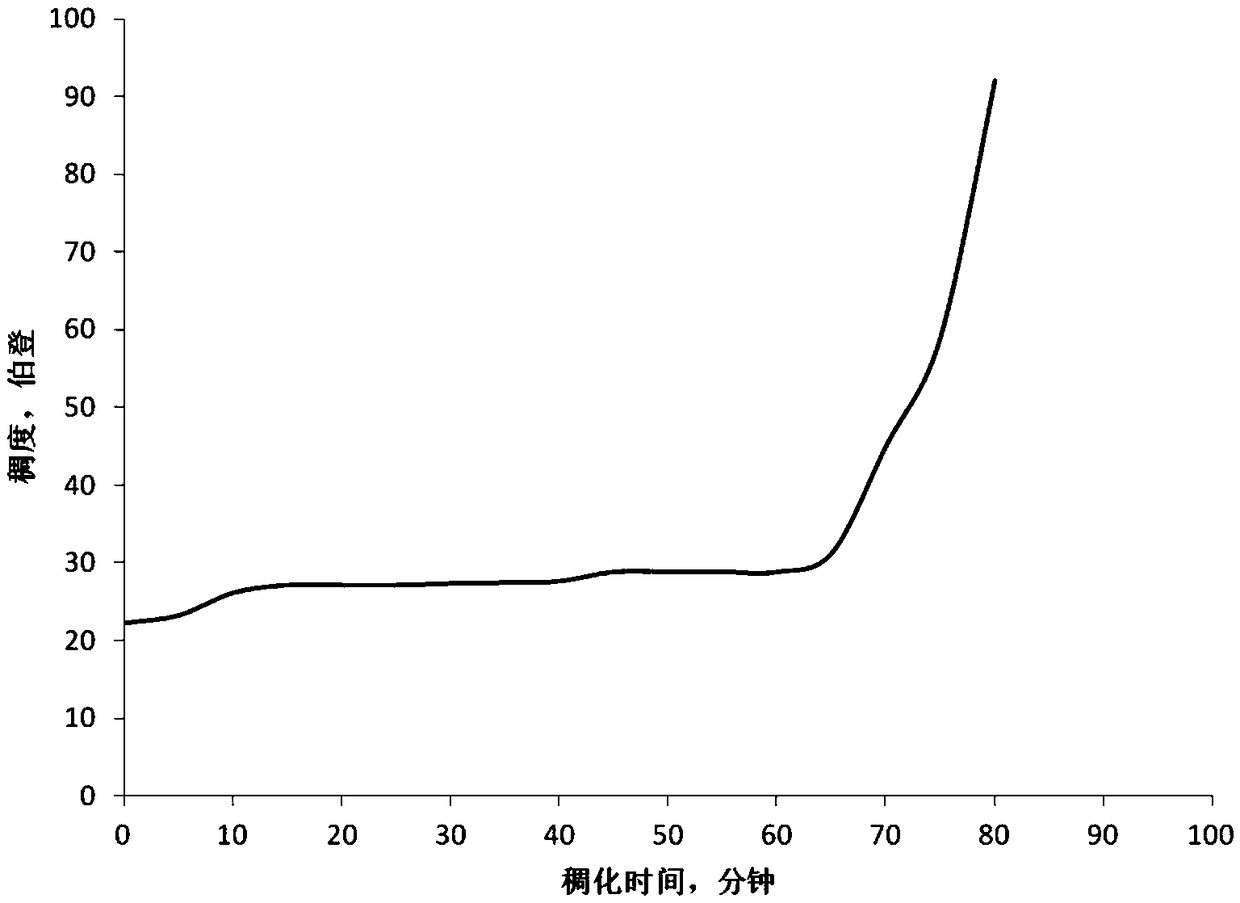

[0049] The measured performance parameters of the cement slurry are shown in Table 1. figure 2 When the amount of ...

Embodiment 3

[0052] This embodiment provides a broad-spectrum chlorine-free coagulation accelerator accelerator for cement used in oilfield well cementing, which is prepared by the following steps:

[0053] Weigh 1 part by weight of sodium aluminate, 1 part by weight of calcium formate, 1.5 parts by weight of aluminum sulfate, and 1.5 parts by weight of hydroxyapatite, and pour them into a mixing device and mix them uniformly to obtain the early strength agent.

[0054] This embodiment also provides a kind of cement slurry that is used for oil field well cementing, and it is prepared through the following steps:

[0055] Take by weighing 700g grade G oilfield cement, 21g early strength agent (accounting for 3.0% of cement mass), 17.5g fluid loss reducer DRF-300S, 4.2g dispersant DRS-1S and 301g water, the above components Mix to make cement slurry.

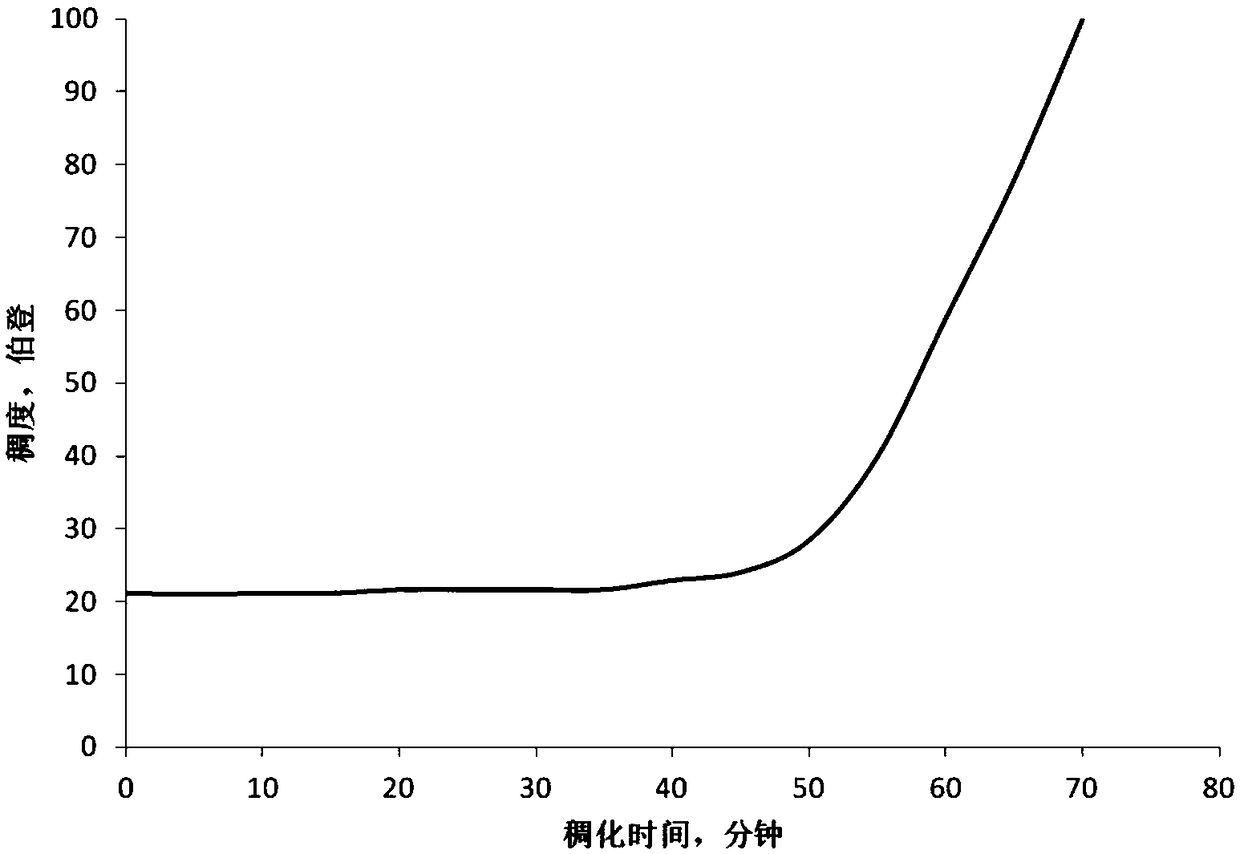

[0056] The measured performance parameters of the cement slurry are shown in Table 1. image 3 When the amount of early strength agent of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com