Method for preparing cement slurry thixotropic agent of plugging oil well

A technology of oil well cement slurry and thixotropic agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems affecting the plugging performance of thixotropic agent, the decrease of thixotropic performance, and the increase of water loss, and achieve viscosity Effects of enhancing, reducing water loss, and enhancing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

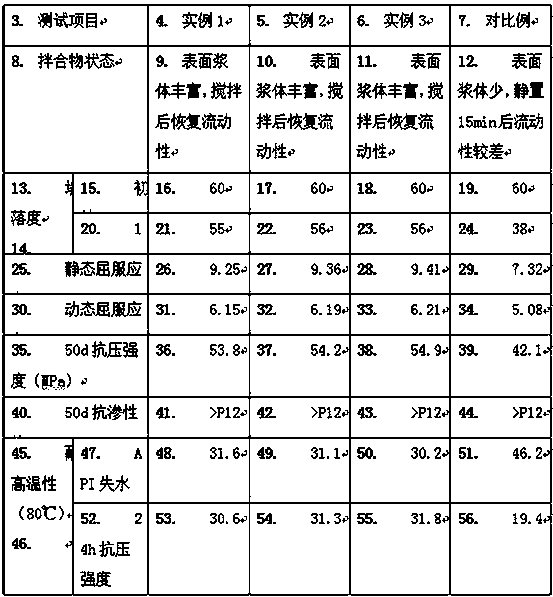

Examples

example 1

[0026] Methyl methacrylate and styrene are mixed in a mass ratio of 2:3 to obtain a mixed monomer. In parts by weight, 40 parts of a mixed monomer, 5 parts of a mass fraction of 30% sodium hydroxide solution and 30 Add one part of deionized water into a three-necked flask with a stirrer and a ventilation tube, heat up to 75°C, feed nitrogen, start the agitator, stir at a speed of 200r / min, add 1 part of potassium thiosulfate to the three-necked flask, React for 1.5h to obtain seed emulsion; in parts by weight, after cooling the above-mentioned three-necked flask to 68°C, add 30 parts of butyl acrylate, 20 parts of methyl methacrylate, 2 parts of potassium thiosulfate, 20 parts of Parts of sodium carbonate solution with a mass fraction of 25%, 3 parts of sodium lauryl sulfate, stirred and reacted for 3 hours, heated to 80°C, then incubated for 30 minutes, cooled to room temperature naturally, and discharged to obtain a soap-free emulsion, which is set aside; by weight By counti...

example 2

[0028] Methyl methacrylate and styrene are mixed in a mass ratio of 2:3 to obtain a mixed monomer. In parts by weight, 45 parts of a mixed monomer, 6 parts of a mass fraction of 30% sodium hydroxide solution and 35 Add one part of deionized water into a three-necked flask with a stirrer and a ventilation tube, heat up to 77°C, feed nitrogen, start the agitator, stir at a speed of 225r / min, add 2 parts of potassium thiosulfate to the three-necked flask, React for 1.7h to obtain seed emulsion; in parts by weight, after cooling the above-mentioned three-necked flask to 70°C, add 35 parts of butyl acrylate, 25 parts of methyl methacrylate, 3 parts of potassium thiosulfate, 23 parts of Parts of sodium carbonate solution with a mass fraction of 25%, 4 parts of sodium lauryl sulfate, stirred and reacted for 3 hours, heated to 83°C, then incubated for 35 minutes, cooled to room temperature naturally, and discharged to obtain a soap-free emulsion for subsequent use; parts by weight By ...

example 3

[0030] Methyl methacrylate and styrene are mixed in a mass ratio of 2:3 to obtain a mixed monomer. In parts by weight, 50 parts of a mixed monomer, 7 parts of a mass fraction of 30% sodium hydroxide solution and 40 Add one part of deionized water into a three-necked flask with a stirrer and a ventilation tube, heat up to 78°C, feed nitrogen, start the agitator, stir at a speed of 250r / min, add 3 parts of potassium thiosulfate to the three-necked flask, React for 2.0 hours to obtain seed emulsion; in parts by weight, after cooling the above-mentioned three-necked flask to 72°C, add 40 parts of butyl acrylate, 30 parts of methyl methacrylate, 4 parts of potassium thiosulfate, 25 parts of Parts of sodium carbonate solution with a mass fraction of 25%, 5 parts of sodium lauryl sulfate, stirred and reacted for 4 hours, heated to 85°C, then incubated for 40 minutes, cooled to room temperature naturally, and discharged to obtain a soap-free emulsion, which is set aside; by weight Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com