Ceramic micro-needle crystal plate and preparation method thereof

A ceramic micro- and needle-crystal technology is applied in the field of medical beauty equipment, which can solve the problems of insufficient morphology consistency of mesh silicon micro-needles, insufficient micro-needle strength, unsatisfactory puncture effect, poor biocompatibility, etc., and achieves stable and reliable preparation methods. The effect of high drug absorption efficiency and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

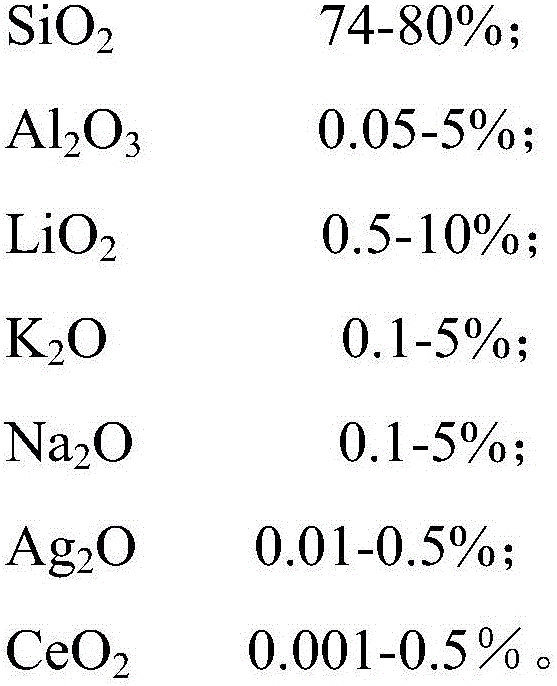

[0038] Prepare ceramic microneedle wafer raw material oxide powder, this powder is made up of the following components by mass percentage:

[0039]

[0040] Prepare ceramic microneedle wafers as follows:

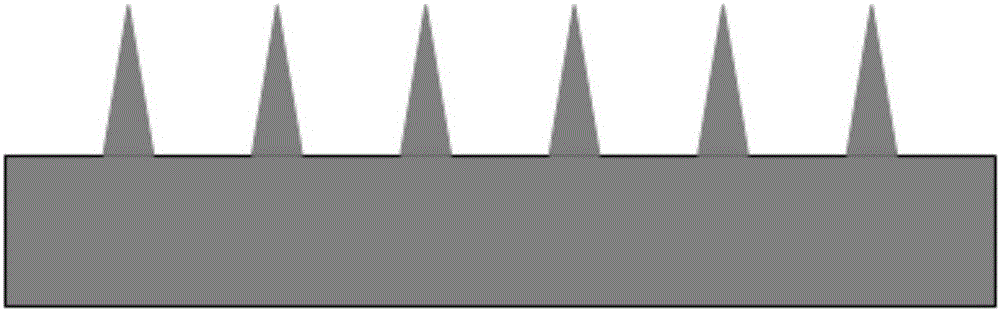

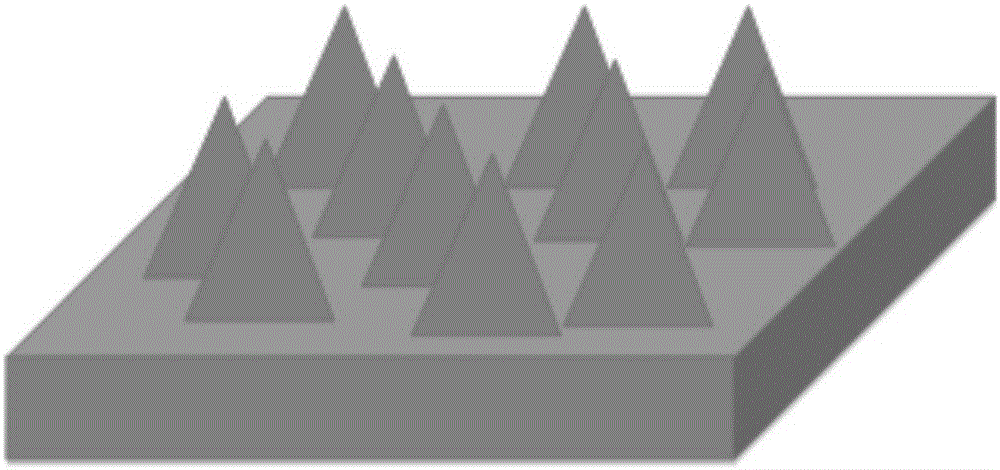

[0041] 1) Prepare a stainless steel mother board, cut the mother board into a rectangle and etch the surface of the mother board to obtain an array of inverted conical needle-shaped depressions, the diameter of the conical bottom surface is 150 μm, and the distance between the centers of the bottom surface is 300 μm;

[0042] 2) mixing the prepared wafer raw materials, and finally coating the raw material mixture on the surface of the motherboard;

[0043] 3) Sintering the raw material mixture at 900°C to obtain a wafer;

[0044] 4) Separate the motherboard and the wafer, and cut the wafer to the required size.

[0045] The thickness of the obtained microneedle wafer is 250 μm, and there are microneedles distributed in an array on the surface. and the spacing between t...

Embodiment 2

[0047] Prepare ceramic microneedle wafer raw material oxide powder, this powder is made up of the following components by mass percentage:

[0048]

[0049] Prepare ceramic microneedle wafers as follows:

[0050]1) Prepare a stainless steel mother board, cut the mother board into a rectangle and etch the surface of the mother board to obtain an array of inverted conical needle-shaped depressions, the diameter of the conical bottom surface is 120 μm, and the distance between the centers of the bottom surface is 200 μm;

[0051] 2) mixing the prepared wafer raw materials, and finally coating the raw material mixture on the surface of the motherboard;

[0052] 3) Sintering the raw material mixture at 1200°C to obtain a wafer;

[0053] 4) Separate the motherboard and the wafer, and cut the wafer to the required size.

[0054] The thickness of the obtained microneedle wafer is 450 μm, and there are microneedles distributed in an array on the surface. and the spacing between t...

Embodiment 3

[0056] Prepare ceramic microneedle wafer raw material oxide powder, this powder is made up of the following components by mass percentage:

[0057]

[0058] Prepare ceramic microneedle wafers as follows:

[0059] 1) Prepare a stainless steel mother board, cut the mother board into a rectangle and etch the surface of the mother board to obtain an array of inverted conical needle-shaped depressions, the diameter of the conical bottom surface is 120 μm, and the distance between the centers of the bottom surface is 300 μm;

[0060] 2) mixing the prepared wafer raw materials, and finally coating the raw material mixture on the surface of the motherboard;

[0061] 3) Sintering the raw material mixture at 1100°C to obtain a wafer;

[0062] 4) Separate the motherboard and the wafer, and cut the wafer to the required size.

[0063] The thickness of the obtained microneedle wafer is 450 μm, and there are microneedles distributed in an array on the surface. The pitch between the ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com