PET polyester film antistatic agent and preparation method thereof

A technology of antistatic agent and polyester film, applied in the field of antistatic agent and its preparation, can solve problems such as limited application, and achieve the effect of reducing surface resistance and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

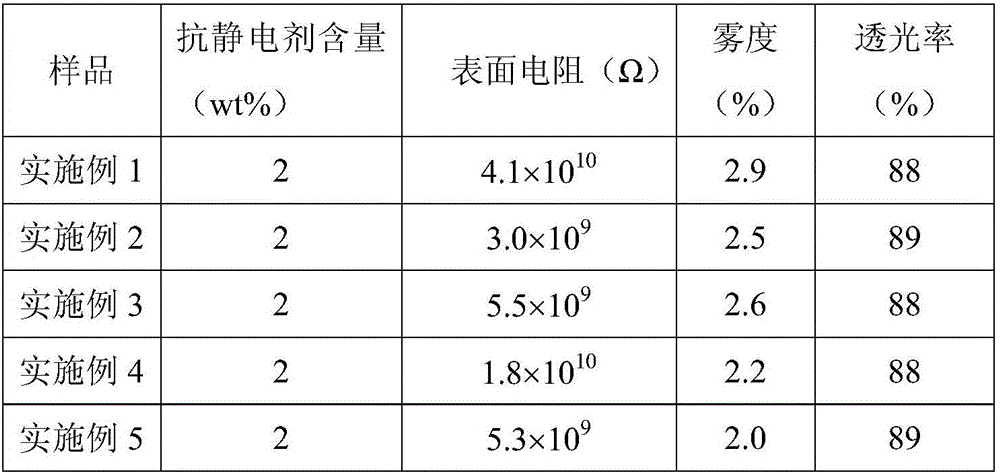

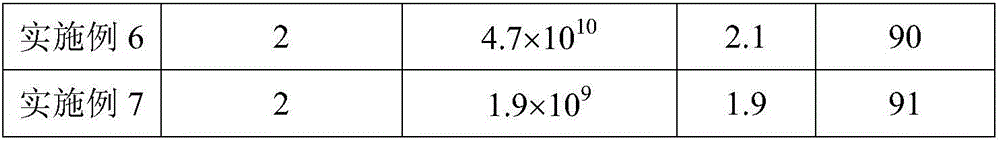

Examples

Embodiment 1

[0033] Synthesis of Aliphatic Polyester Oligomers. Take 146g of adipic acid, 62g of ethylene glycol, and 1% by mass fraction of p-toluenesulfonic acid, mix and esterify at 160°C for 1 hour. Then evacuate to reduce the vacuum of the system to below 100Pa, and continue the polycondensation for 0.5h. The product was then allowed to cool and THF was added to dissolve the product. Precipitate in ether and dry to obtain an aliphatic polyester oligomer with a molecular weight of 400 g / mol.

[0034] Synthesis of Unsaturated Aliphatic Polyester Oligomers. Take 60 g of the above-mentioned aliphatic polyester oligomer and 14 g of maleic anhydride, and the molar ratio of the two is 1:1. After mixing, esterify at 160°C for 4h. After cooling, THF was added to dissolve the product, followed by precipitation in ether, followed by drying to obtain an unsaturated aliphatic polyester oligomer. The molecular weight is 500 g / mol.

[0035] Synthesis of Copolymer of Unsaturated Aliphatic Polye...

Embodiment 2

[0037] Synthesis of Aliphatic Polyester Oligomers. Take 146g of adipic acid, 62g of ethylene glycol, and 1% by mass fraction of p-toluenesulfonic acid, mix and esterify at 160°C for 1 hour. Then evacuate to reduce the vacuum of the system to below 100Pa, and continue the polycondensation for 0.5h. The product was then allowed to cool and THF was added to dissolve the product. Precipitate in ether and dry to obtain an aliphatic polyester oligomer with a molecular weight of 400 g / mol.

[0038] Synthesis of Unsaturated Aliphatic Polyester Oligomers. Take 60 g of the above-mentioned aliphatic polyester oligomer and 14 g of maleic anhydride, and the molar ratio of the two is 1:1. After mixing, esterify at 160°C for 4h. After cooling, THF was added to dissolve the product, followed by precipitation in ether, followed by drying to obtain an unsaturated aliphatic polyester oligomer. The molecular weight is 500 g / mol.

[0039] Synthesis of Copolymer of Unsaturated Aliphatic Polye...

Embodiment 3

[0041] Synthesis of Aliphatic Polyester Oligomers. Take 146g of adipic acid, 62g of ethylene glycol, and 1% by mass fraction of p-toluenesulfonic acid, mix and esterify at 160°C for 1 hour. Then evacuate to reduce the vacuum of the system to below 100Pa, and continue the polycondensation for 0.5h. The product was then allowed to cool and THF was added to dissolve the product. Precipitate in ether and dry to obtain an aliphatic polyester oligomer with a molecular weight of 400 g / mol.

[0042] Synthesis of Unsaturated Aliphatic Polyester Oligomers. Take 60 g of the above-mentioned aliphatic polyester oligomer and 14 g of maleic anhydride, and the molar ratio of the two is 1:1. After mixing, esterify at 160°C for 4h. After cooling, THF was added to dissolve the product, followed by precipitation in ether, followed by drying to obtain an unsaturated aliphatic polyester oligomer. The molecular weight is 500 g / mol.

[0043]Synthesis of Copolymer of Unsaturated Aliphatic Polyes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com