PVC environment-friendly stabilizer

An environmentally friendly stabilizer and unsaturated technology, applied in the field of material chemistry, can solve problems such as the inability to effectively control the degradation of PVC, and achieve the effects of better thermal stability, low energy consumption and low operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

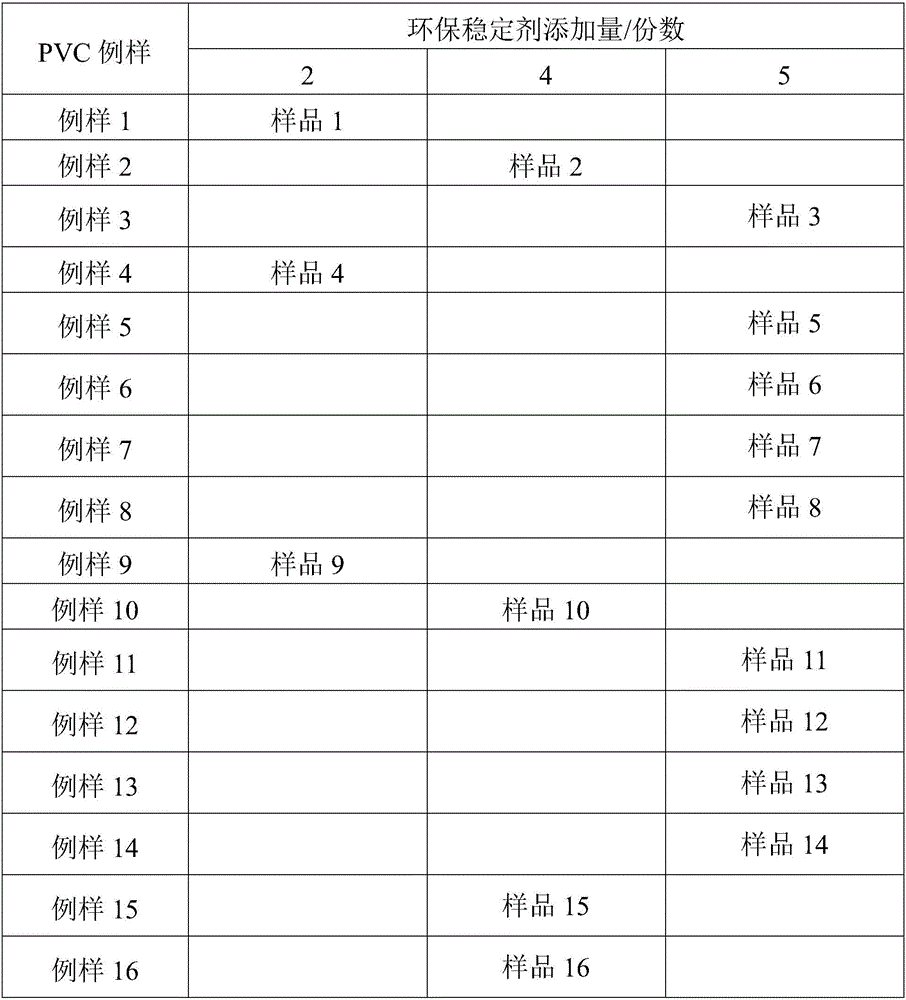

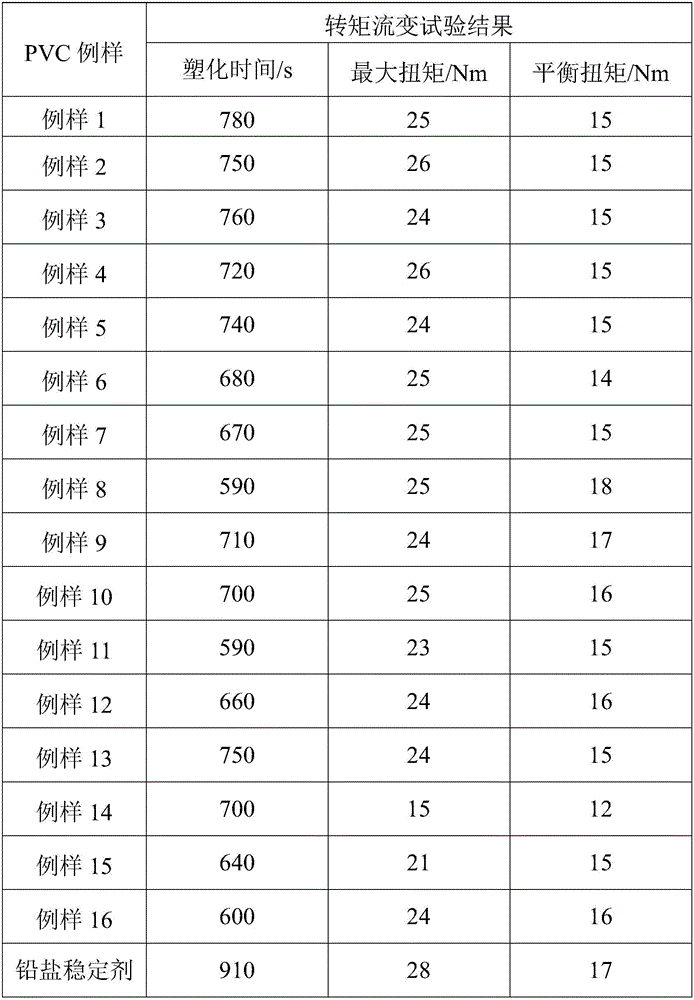

Examples

Embodiment 1

[0018] In the first step, glycerin and butenedioic acid are added into the stirred reactor at a molar ratio of 1.0:2.0, and reacted at 80°C for 4-6 hours under normal pressure (or 10-12 hours under normal pressure and room temperature) to obtain unsaturated glycerol ester; Calcium hydroxide and glycerol equimolarity were added to the unsaturated glycerol ester, stirred and reacted at normal temperature and pressure for 2 hours.

[0019] In the second step, the above product was dried at 105°C for 12 hours, then placed in a vacuum oven at 40°C for 6 hours, and crushed through a 100-mesh sieve to obtain a colorless powder calcium unsaturated glycerol ester calcium salt.

Embodiment 2

[0021] In the first step, add glycerin and butenedioic acid into the stirred reactor at a molar ratio of 0.5:1.0, and react for 2-10 hours under normal pressure at 50-150°C to obtain an unsaturated glycerol ester; Stir in the unsaturated glycerol ester at room temperature and pressure for 6 hours.

[0022] In the second step, the above product was dried at 105°C for 12 hours, then placed in a vacuum oven at 40°C for 6 hours, and crushed through a 100-mesh sieve to obtain a colorless powder calcium unsaturated glycerol ester calcium salt.

Embodiment 3

[0024] In the first step, glycerin and butenedioic acid are added to the stirred reactor at a molar ratio of 0.5:1.0, and react at normal pressure and 150°C for 4 hours to obtain unsaturated glycerol ester; The ester was stirred at room temperature and pressure for 4 h.

[0025] In the second step, the above product was dried at 105°C for 12 hours, then placed in a vacuum oven at 40°C for 6 hours, and crushed through a 100-mesh sieve to obtain a colorless powder calcium unsaturated glycerol ester calcium salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com