Block copolymer composition

A block copolymer and composition technology, applied in the field of block copolymer composition, can solve problems such as non-compliance, and achieve the effect of maintaining transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] Preparation of Block Copolymer Compositions

[0052] The preparation method of the block copolymer composition of the present invention comprises first carrying out the polymerization reaction of the block copolymer (A), and then adding the compound (B) of the present invention, and after removing the solvent and drying, the compound of the present invention can be obtained block copolymer composition. In more detail, the polymerization reaction of the block copolymer (A) in the block copolymer composition of the present invention is carried out by dissolving the monomer in a solvent to carry out the polymerization reaction, and then adding the compound (B) of the present invention, and then adding the compound (B) in the solvent Forming a polymer glue in the middle, the above-mentioned glue usually contains 10% by weight to 35% by weight of solids, and the aforementioned glue can be re-concentrated to 50% by weight to 99% by weight of solids in advance by decompression...

experiment example 1~11

[0078] The raw materials used are:

[0079] 1. The vinyl aromatic monomer is styrene (referred to as SM).

[0080] 2. The conjugated diene monomer is 1,3-butadiene (abbreviated as BD).

[0081] 3. The initiator (C) is n-butyllithium (n-BuLi for short) with a concentration of 8% by weight.

[0082] 4. The polar compound (E) is tetrahydrofuran (THF for short).

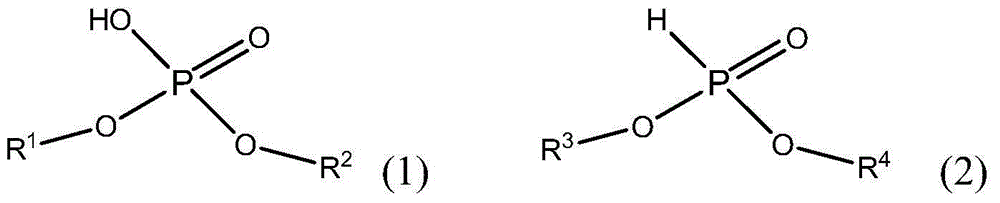

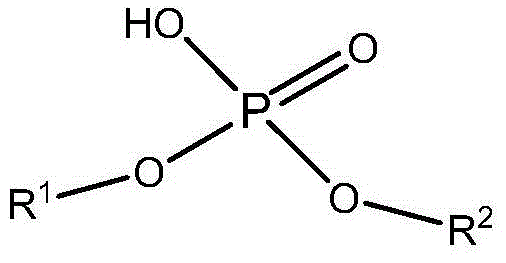

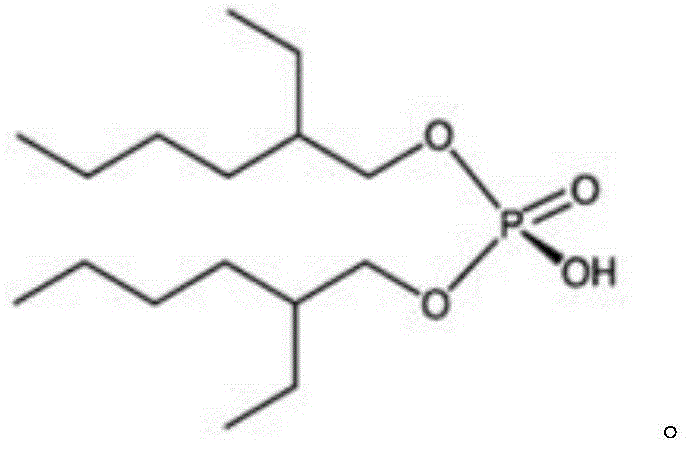

[0083] 5. Compounds (B) include (1) dioctyl phosphate, (2) diphenyl phosphite, and (3) 3,5,5-trimethylhexanoic acid.

[0084] 6. As the solvent (D), cyclohexane is used.

[0085] First, in the presence of nitrogen, the polymerization is carried out in a batch reactor, wherein the reaction pressure is about 1Kg / cm 2 ~3Kg / cm 2 , The reaction temperature is 50°C to 120°C, and the reaction time is about 60 minutes to 150 minutes. The volume of the reactor is 160 liters, the solvent (D) uses cyclohexane, and the order of feeding and the weight of raw materials are as shown in Table 1. After the above reaction was compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com