Water-based flame-retardant epoxy resin coating

A technology of epoxy resin coatings and epoxy resins, which is applied in the direction of epoxy resin coatings, fireproof coatings, polyether coatings, etc., can solve the problems of less research on water-based epoxy resin coatings, and achieve obvious product differentiation and coating film High hardness and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

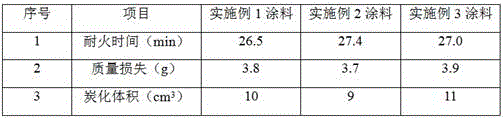

Examples

Embodiment 1

[0027] A water-based flame-retardant epoxy resin coating composed of three components A, B, and C in a mass ratio of 5:1:1;

[0028] The A component is composed of the following raw materials in parts by weight: 90 parts of bisphenol A epoxy resin, 20 parts of polyoxyethylene alkyl ester, and 10 parts of polyacrylate;

[0029] The B component is composed of the following raw materials in parts by weight: 20 parts of triethylenetetramine, 5 parts of titanium dioxide, 8 parts of pigments, 110 parts of talc, and 30 parts of water;

[0030] The C component is composed of the following raw materials in parts by weight: 1 part of wetting and dispersing agent, 1.6 parts of defoaming agent, 1.2 parts of leveling agent, 20 parts of phosphorus-nitrogen composite flame retardant, 5 parts of hypophosphite flame retardant, 6 parts of phosphate.

[0031] A method for preparing the above-mentioned water-based flame-retardant epoxy resin coating includes the following steps:

[0032] 1) Mix and stir t...

Embodiment 2

[0036] A water-based flame-retardant epoxy resin coating composed of three components A, B, and C in a mass ratio of 5:1:1;

[0037] The A component is composed of the following raw materials in parts by weight: 95 parts of bisphenol A epoxy resin, 15 parts of polyoxyethylene alkyl ester, and 20 parts of polyacrylate;

[0038] The B component is composed of the following raw materials in parts by weight: 22 parts of triethylenetetramine, 4 parts of titanium dioxide, 9 parts of pigments, 105 parts of talc, and 35 parts of water;

[0039] The C component is composed of the following raw materials in parts by weight: 2.0 parts of wetting and dispersing agent, 1.4 parts of defoaming agent, 1.5 parts of leveling agent, 17 parts of phosphorus-nitrogen composite flame retardant, 5 parts of hypophosphite flame retardant, 6 parts of phosphate.

[0040] A method for preparing the above-mentioned water-based flame-retardant epoxy resin coating includes the following steps:

[0041] 1) Mix and sti...

Embodiment 3

[0045] A water-based flame-retardant epoxy resin coating composed of three components A, B, and C in a mass ratio of 5:1:1;

[0046] The A component is composed of the following raw materials in parts by weight: 100 parts of bisphenol A epoxy resin, 10 parts of polyoxyethylene alkyl ester, and 25 parts of polyacrylate;

[0047] The B component is composed of the following raw materials in parts by weight: 25 parts of triethylenetetramine, 3 parts of titanium dioxide, 10 parts of pigments, 100 parts of talc, and 40 parts of water;

[0048] The C component is composed of the following raw materials in parts by weight: 3.2 parts of wetting and dispersing agent, 1.2 parts of defoaming agent, 1.8 parts of leveling agent, 15 parts of phosphorus-nitrogen composite flame retardant, 6 parts of hypophosphite flame retardant, 5 parts of phosphate.

[0049] A method for preparing the above-mentioned water-based flame-retardant epoxy resin coating includes the following steps:

[0050] 1) Mix and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com