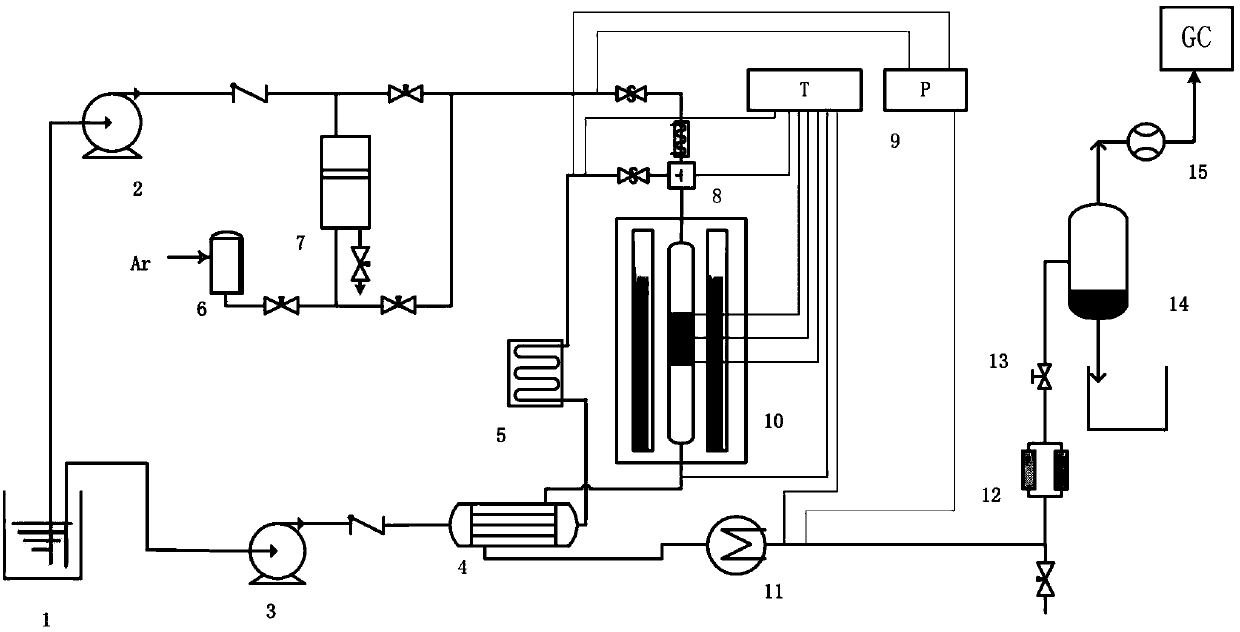

A method and device for continuous supercritical water fixed-bed catalytic gasification of organic matter

A technology of supercritical water and organic matter, applied in the direction of gasification process, manufacture of combustible gas, bulk chemical production, etc. The effect of gasification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

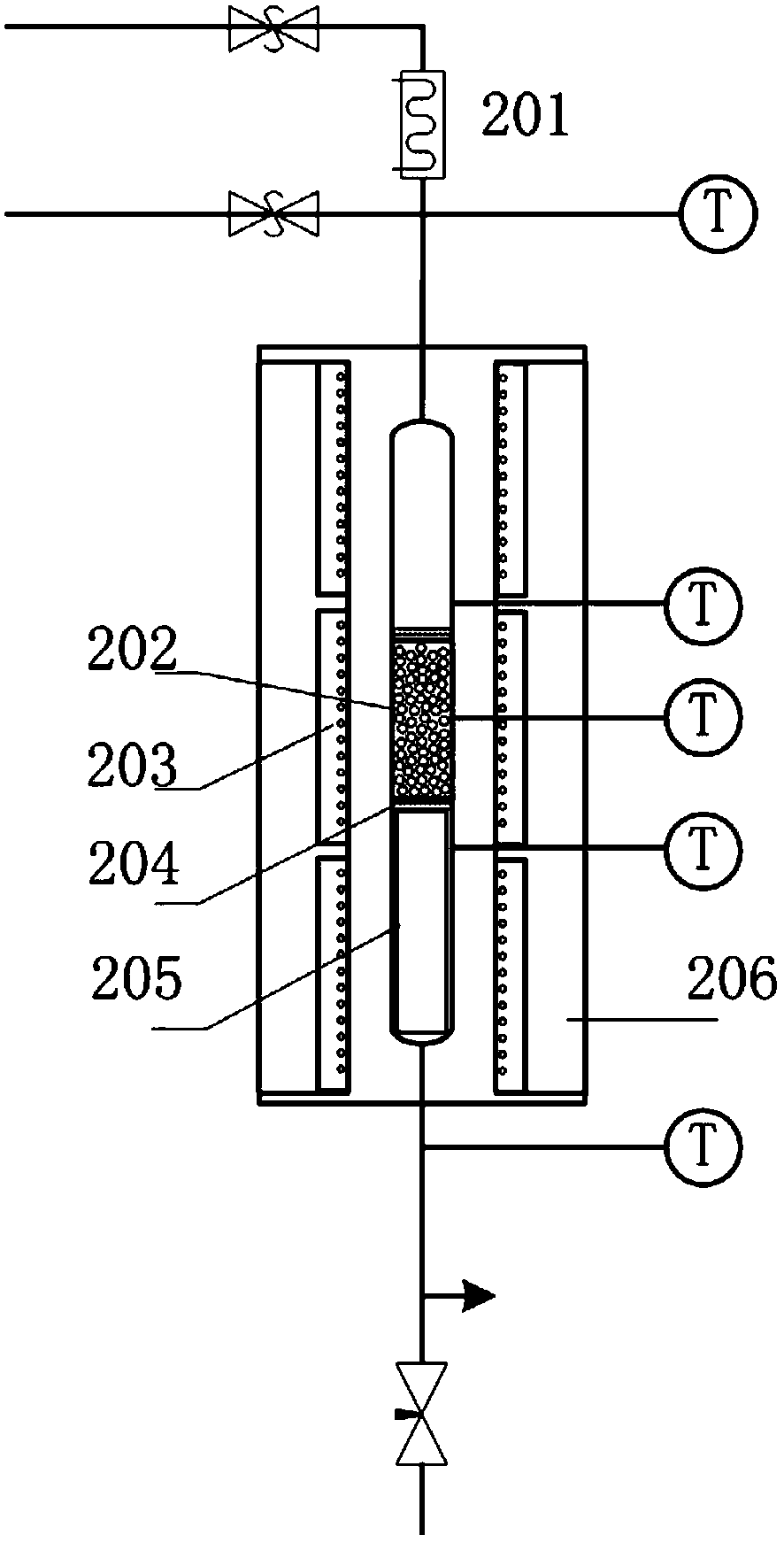

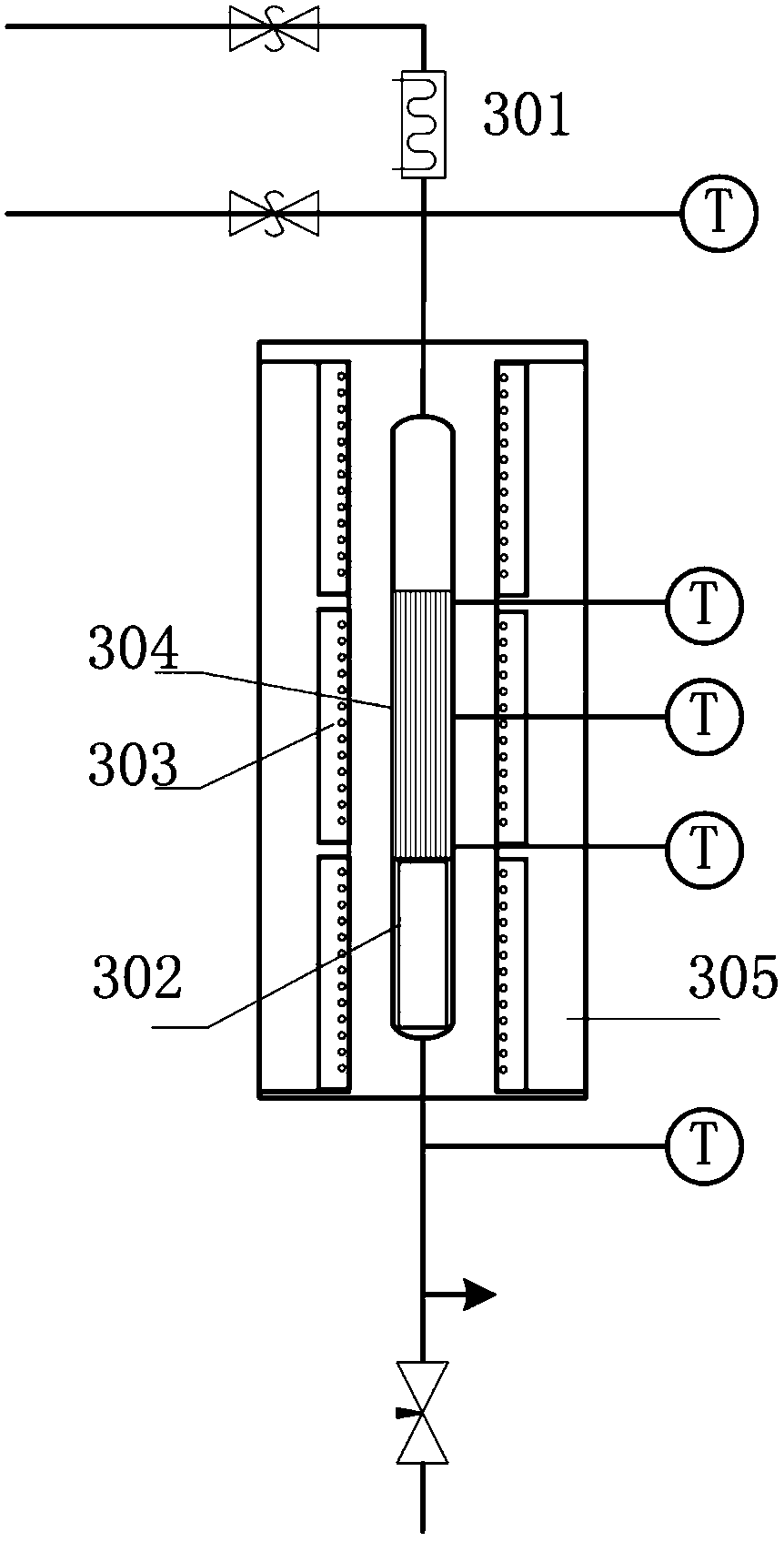

Embodiment 1

[0038] A continuous supercritical water fixed bed device was used to study the hydrogen production by catalytic gasification of glucose solution. A 5% Ru / C catalyst was used. The catalyst was placed in the middle of the reactor. The particle size of the catalyst was between 100-200 mesh. The height is 20cm, the residence time of the material in the reactor is 30s, the reaction temperature is 400-500°C, the pressure is 23MPa, and the glucose concentration range is 5-20wt.%.

[0039] Experimental research on glucose gasification at different temperatures in a fixed bed shows that the glucose solution with a feed concentration of 10% is nearly completely gasified at 400-500°C. The composition of gas produced at different temperatures is different, and high temperature is conducive to the formation of hydrogen and inhibits the formation of methane. As shown in Table 1:

[0040] Table 1 Variation of glucose gas production with temperature in fixed bed

[0041] (Material concentra...

Embodiment 2

[0048] A continuous supercritical water fixed bed device was used to study the catalytic gasification of depolymerization residual liquid to produce hydrogen. The depolymerization residual liquid used was wastewater after cassava oil production. The depolymerization residual liquid was mainly composed of alcohols, ketones, and esters. The initial COD value of the depolymerization raffinate was 194.6g / L. Ru / C catalyst is used, the catalyst is placed in the middle of the reactor, the catalyst particle size is between 200-300 mesh, the catalyst bed height is 20cm, the residence time of the material in the reactor is about 30s, and the reaction temperature is 400-500°C. Pressure 23MPa.

[0049] The supercritical water gasification of depolymerization raffinate under different temperature, concentration and ruthenium loading conditions was studied in a fixed bed using ruthenium carbon as a catalyst. The results show that under different conditions of temperature, concentration and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com