Metal tube drawing oil

A metal pipe and drawing oil technology, which is applied in the field of metal pipe and metal pipe drawing oil, can solve the problems of dispersion, no uniform quality standard, and small production scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

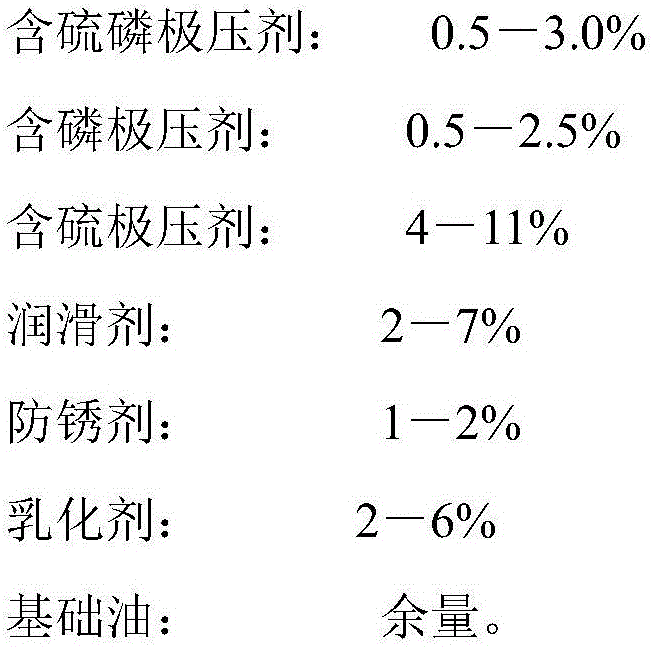

[0019] A metal pipe drawing oil, the main component is base oil, other additives and their percentages are based on the mass of the drawing oil:

[0020] ZnDDP 0.5%

[0021] ElCO Phosphates and Phosphites (Oil Soluble) 2.5%

[0022] Sulfurized isobutylene 2%

[0023] Sulfurized fatty acid esters 5%

[0024] Trimethylolpropane Oleate 2%

[0025] T705A rust inhibitor 2%

[0026] Fatty alcohol polyoxyethylene ether 1%

[0027] Polyoxyethylene (4EO) sorbitan monolaurate 3%

[0028] Base oil balance

Embodiment 2

[0030] A metal pipe drawing oil, the main component is base oil, other additives and their percentages are based on the mass of the drawing oil:

[0031] ZnDDP 3.0%

[0032] ElCO phosphates and phosphites (oil soluble) 0.5%

[0033] Sulfurized isobutylene 6%

[0034] Sulfurized fatty acid esters 2%

[0035] Trimethylolpropane Oleate 7%

[0036] T705A rust inhibitor 1%

[0037] Fatty alcohol polyoxyethylene ether 3%

[0038] Polyoxyethylene (4EO) sorbitan monolaurate 1%

[0039] Base oil: balance

Embodiment 3

[0041] A metal pipe drawing oil, the main component is base oil, other additives and their percentages are based on the mass of the drawing oil:

[0042] ZnDDP 1.5%

[0043] ElCO Phosphates and Phosphites (Oil Soluble) 2%

[0044] Sulfurized isobutylene 3%

[0045] Sulfurized fatty acid esters 3.5%

[0046] Trimethylolpropane Oleate 5%

[0047] T705A rust inhibitor 1.5%

[0048] Fatty alcohol polyoxyethylene ether 2%

[0049] Polyoxyethylene (4EO) sorbitan monolaurate 2%

[0050] Base oil: balance

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com