Aroma enhancement method for baijiu fermentation

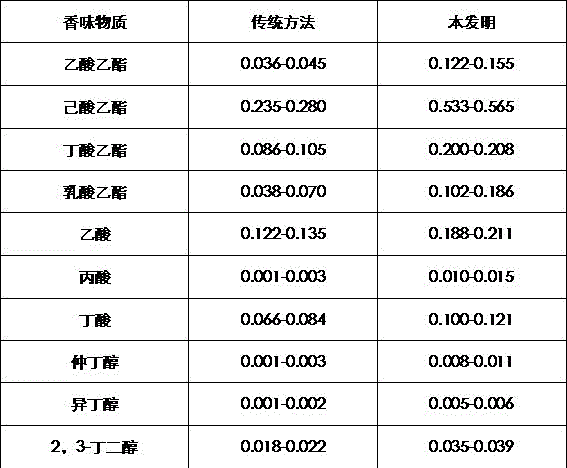

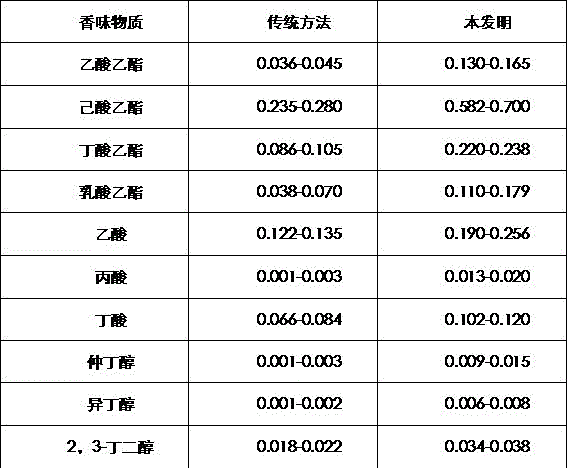

A liquor and main fermentation technology, applied in the field of winemaking, can solve the problems of low water content and acidity, affecting the taste and quality of liquor, and affecting the production of esters, etc., to increase the content, avoid secondary fermentation, and promote the effect of heating and deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 11t of pit grains into the pit, the height of the grains exceeds the mouth of the pit, insert a nozzle that circulates yellow water in the pit of the grain, and then cover the surface of the pit mud to seal the pit to begin fermentation. After the previous main fermentation produces ethanol, the fermentation enters the fragrance-producing period. During the first day of the fragrance-producing period, yellow water is sprayed periodically to the fermented grains in the pit, and the yellow water is sprayed at intervals of 4 hours for 3 minutes. The yellow water flow rate is 18Kg per minute, which can effectively avoid affecting production. During the fermentation process, it also reduces the amount of scouring substances in the upper fermented grains, such as starch, dextrin, fragrance precursors, and microbial lysates, that will be flushed to the bottom of the pit with yellow water due to circulation. , Fragrance precursor substances, microbial lysates, etc. to obtain ...

Embodiment 2

[0023] Add 12t grain grains to the pit, and the height of grain grains exceeds the mouth of the pit. Insert a nozzle that circulates yellow water into the grain grains with high yards, and then cover the surface of the pit mud to seal the pit to begin fermentation. After ethanol is produced by fermentation, the fermentation enters the fragrance-producing period. During the fifth day of the fragrance-producing period, yellow water is sprayed periodically to the fermented grains in the pit, and the yellow water is sprayed at intervals of 6 hours for 3.5 minutes. The yellow water flow rate is 19Kg per minute; Then take yellow water from other pits or spare yellow water storage tanks to flood the pits, immerse the fermented ferments to the mouth of the pit, and submerge the fermented ferments below the mouth of the pit; the yellow water will be drawn on the 35th day of the fragrance period. , The yellow water is deposited in the yellow water collection pit at the bottom of the pit, ...

Embodiment 3

[0028] Add 14t grain grains to the pit, and the height of grain grains exceeds the mouth of the pit. Insert a nozzle that circulates yellow water in the grain grains with high yards, and then cover the surface of the pit mud to seal the pit to begin fermentation. After the ethanol is produced by fermentation, the fermentation enters the aroma-producing period. During the eighth day of the aroma-producing period, yellow water is sprayed on the fermented grains in the pit at intervals of 7 hours for 4 minutes, and the yellow water flow rate is 20Kg per minute; on the 24th day of the aroma period Then draw yellow water from other pits or spare yellow water storage tanks to flood the pits, immerse the fermented ferments to the mouth of the pit, and immerse the fermented ferments below the mouth of the pit; the yellow water will be drawn on the 36th day of the fragrance period. Yellow water is deposited in the yellow water collection pit at the bottom of the pit, pumped into containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com