Production method of continuous casting of titanium-containing austenitic stainless steel round tube blanks for seamless steel tubes

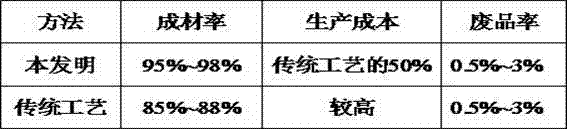

A technology of austenitic stainless steel and seamless steel pipe, applied in the field of iron and steel smelting, can solve problems such as inapplicability, and achieve the effects of low production cost, improved yield and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

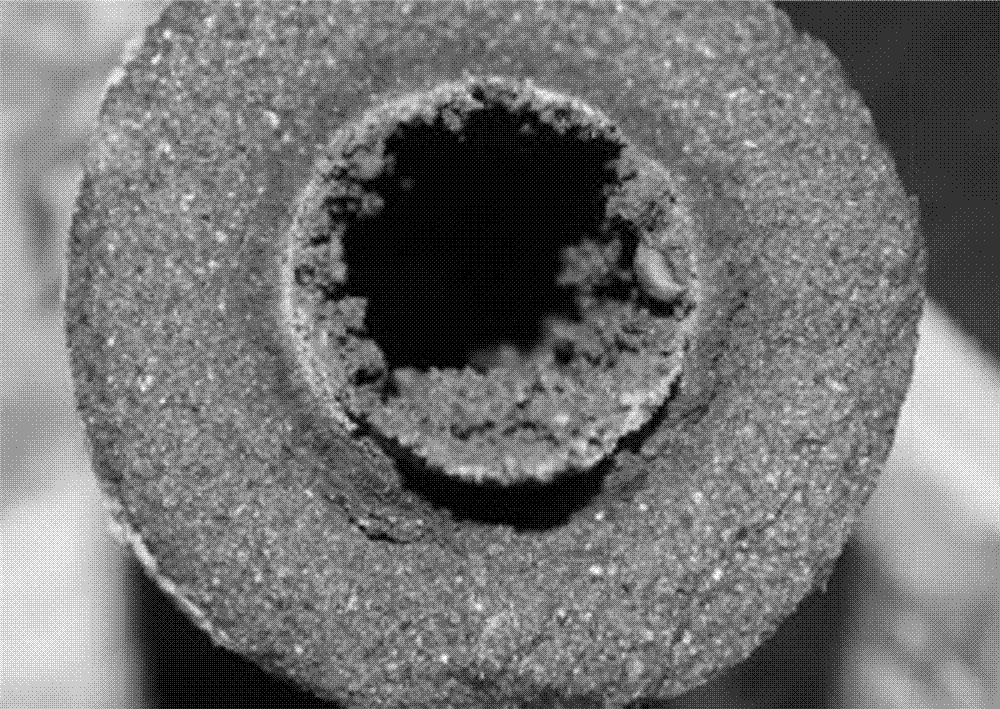

Image

Examples

Embodiment 1

[0039] The type of steel smelted in this embodiment is 06Cr18Ni11Ti, the capacity of the AOD and LF refining furnaces is 30 tons, and the ladle used is a magnesia-carbon brick ladle.

[0040] The mass percentage ratio of 06Cr18Ni11Ti in the national standard is: C ≤ 0.08; Si ≤ 1.00; Mn ≤2.00; Cr 17.00-19.00; Ni 9.00-12.00; Ti ≥ 5*C; P ≤ 0.045; ;

[0041] The present invention controls the mass percentage distribution ratio of the composition of this steel type to:

[0042] C ≤ 0.03; Si 0.30-0.75; Mn 0.80-1.50; Cr 17.00-18.00;

[0043] Ni 9.00-9.30; Ti 5*C-0.25; P ≤ 0.045; S ≤ 0.005; N ≤ 0.030.

[0044] The rest is Fe and unavoidable impurities.

Embodiment 2

[0046] The type of steel smelted in this embodiment is 0Cr18Ni9Ti, the capacity of the AOD and LF refining furnaces is 30 tons, and the ladle used is a magnesia-carbon brick ladle.

[0047] The mass percentage ratio of 0Cr18Ni9Ti in the national standard is: C ≤ 0.08; Si ≤ 1.00; Mn ≤2.00; Cr 17.00-19.00; Ni 8.00-11.00; Ti ≥ 5*C; P ≤ 0.040; ;

[0048] The present invention controls the mass percentage distribution ratio of the composition of this steel type to:

[0049] C ≤ 0.03; Si 0.30-0.75; Mn 0.80-1.50; Cr 17.00-18.00;

[0050] Ni 8.00-8.30; Ti 5*C-0.25; P ≤ 0.040; S ≤ 0.005; N ≤ 0.030.

[0051] The rest is Fe and unavoidable impurities.

[0052] The specific steps of the production method for the round tube billet continuous casting of the titanium-containing austenitic stainless steel seamless steel pipe of embodiment 1 and 2 are as follows:

[0053] 1) Add 10kg of recarburizer per ton of steel into the AOD furnace with AOD mixed with steel. The initial carbon content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com