Deep-hole drilling system and method for increasing precision and efficiency of deep curtain grouting hole thereof

A curtain grouting and drilling depth technology, applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve the problems of increased construction cost, no longer popularized and adopted, low construction efficiency, etc., to reduce construction cost and shorten the The effect of simple construction period and construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

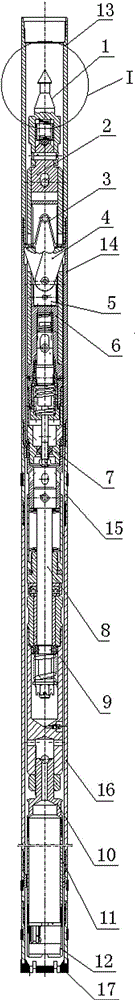

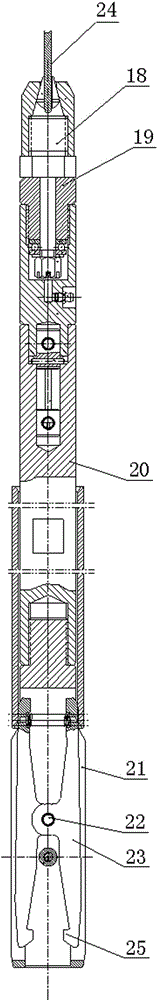

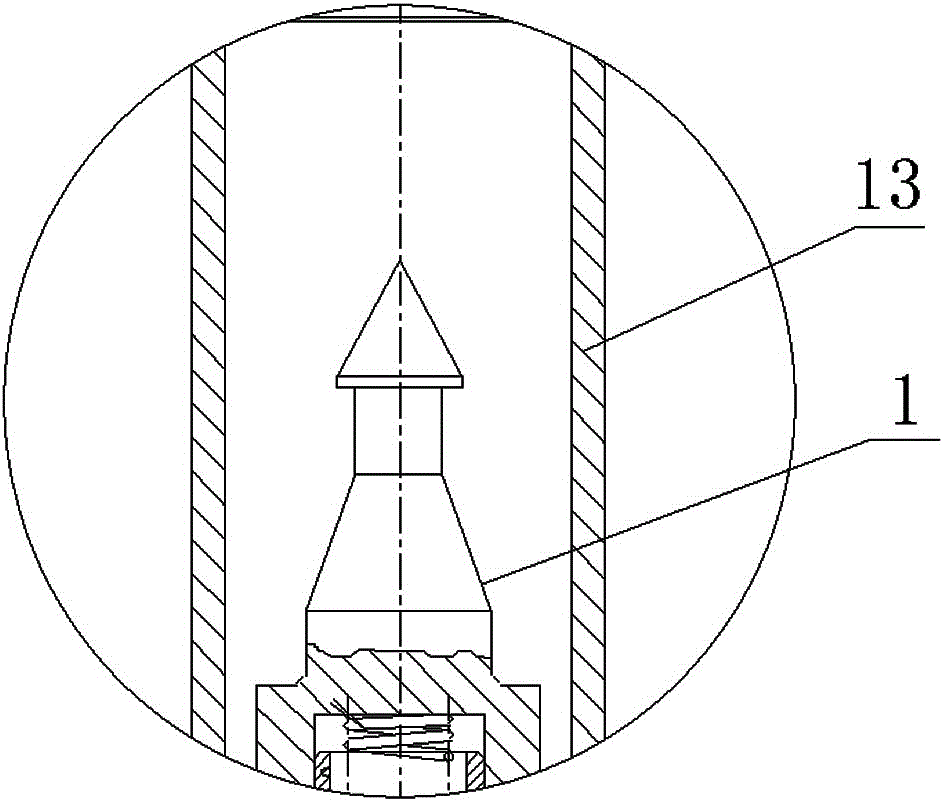

[0023] Embodiment one: if Figure 1~3 As shown, a deep hole drilling system, the deep hole drilling system includes a double-tube coring drill and a coring drill overshot, the double-tube coring drill includes a cylinder and is arranged in the cylinder and sequentially Connected fishing spear head 1, fishing spear seat 2, tension spring 3, bullet caliper 4, bullet clamping seat 5, bullet clamping frame 6, suspension joint 7, shaft 8, spring sleeve 9, adjustment joint 10 and rock core inner tube 11, The bottom of the core inner tube 11 is equipped with a spring seat 12, and the cylinder body is composed of a bullet stopper 13, a bullet chamber 14, a hole reamer 15, and an outer core connected sequentially from top to bottom. Tube 16 and drill bit 17, the described coring drill overhauler is composed of connecting rod 18, gland 19, weight 20, fishing hook frame 21 connected sequentially from top to bottom, and described fishing hook frame 21 Two fishing hooks 23 are hinged in t...

Embodiment 2

[0032] Embodiment two: the difference between this embodiment and embodiment one is: the method for improving the drilling accuracy and work efficiency of the deep hole curtain grouting system described in the deep hole drilling system comprises the following steps:

[0033] S1. Connect the drill pipe to the top of the stopper head 13, connect the drill pipe to the power head device of the ground drilling rig, select the drilling position and position the drill bit 17;

[0034] S2, start the power head device of the drilling rig, the drill bit drills into the foundation at a drilling speed of 390r / min, and the drilling pressure is 9KN during drilling, and the drill bit 17 is ground to act on the rock surface at the bottom of the hole, thereby obtaining continuous extension of the drilled hole; During the process, the rock core gradually enters the core inner tube 11 at the lower part of the double-tube core drilling tool. Due to the action of the spring seat 12 at the bottom of...

Embodiment 3

[0039] Embodiment three: the difference between this embodiment and embodiment one is: the method for improving the drilling accuracy and work efficiency of the deep hole curtain grouting system described in the deep hole drilling system comprises the following steps:

[0040]S1. Connect the drill pipe to the top of the stopper head 13, connect the drill pipe to the power head device of the ground drilling rig, select the drilling position and position the drill bit 17;

[0041] S2, start the power head device of the drilling rig, the drill bit drills into the foundation at a drilling speed of 410r / min, and the drilling pressure is 10KN during drilling, and the drill bit 17 is ground to act on the rock surface at the bottom of the hole, thereby obtaining continuous extension of the drilled hole; During the process, the rock core gradually enters the core inner tube 11 at the lower part of the double-tube core drilling tool. Due to the action of the spring seat 12 at the bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com