Device based on injection pump and used for realizing emulsifying combustion of supercharged diesel engine and reducing NOx emission

A diesel engine and jet pump technology, applied in the direction of machine/engine, charging system, mechanical equipment, etc., can solve the problems of low nozzle durability, water and oil stratification, high price, and achieve lower temperature, small structural changes, and lower emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in more detail below in conjunction with accompanying drawing example:

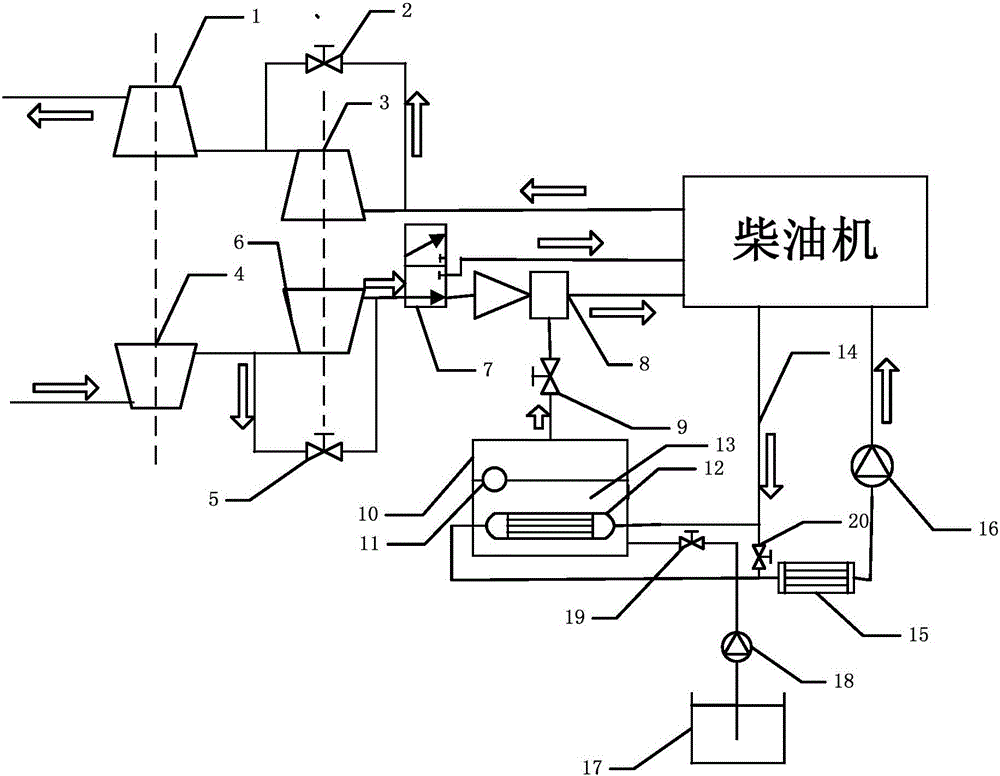

[0012] combine figure 1 , the present invention realizes supercharged diesel engine water-mixed combustion and reduces NOx discharge device based on injection pump, comprises low-pressure stage turbine 1, high-pressure stage turbine 3, turbine bypass valve 2, low-pressure stage compressor 4, compressor bypass valve 5, high-pressure stage Stage compressor 6, two-position three-way reversing valve 7, jet pump 8, water vapor volume control valve 9, closed container 10, water level detector 11, fresh water 13, fresh water heating tube bundle 12, cylinder liner cooling water pipeline 14, cylinder Jacket cooling water cooler 15, cylinder jacket cooling water circulating pump 16, fresh water tank 17, fresh water supply pump 18, check valve 19 and fresh water heating tube bundle bypass valve 20. Among them, the high-pressure stage turbine 3 and the low-pressure stage tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com