Method for depositing nanogold in microfluidic pore passage

A nano-gold, microfluidic technology, applied in chemical instruments and methods, laboratory containers, measuring devices, etc., to achieve high repeatability, low price, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

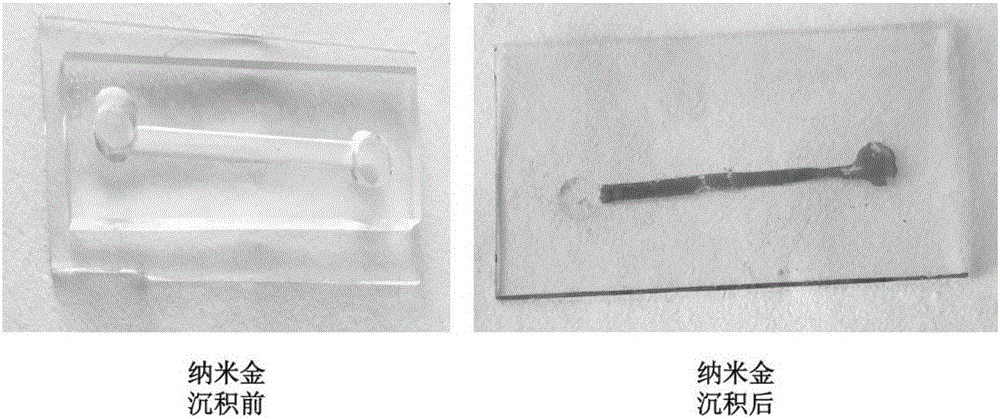

[0022] (1) Pour PDMS liquid A (monomer) and liquid B (initiator) into a beaker at a mass ratio of 10:1, stir with a glass rod for 5 minutes, and then pour it into the above-mentioned petri dish with a silicon wafer.

[0023] (2) Put the petri dish in a concentrated desiccator, pump air with a diaphragm vacuum pump for 1.5 hours to remove air bubbles in PDMS, and then place it in a vacuum oven at 80° C. for 1 hour to solidify.

[0024] (3) After it cools naturally, gently peel off the PDMS from the silicon wafer template, cut it into small pieces with a cutting machine, and then punch holes in the corresponding parts with a manual chip puncher for experimental use.

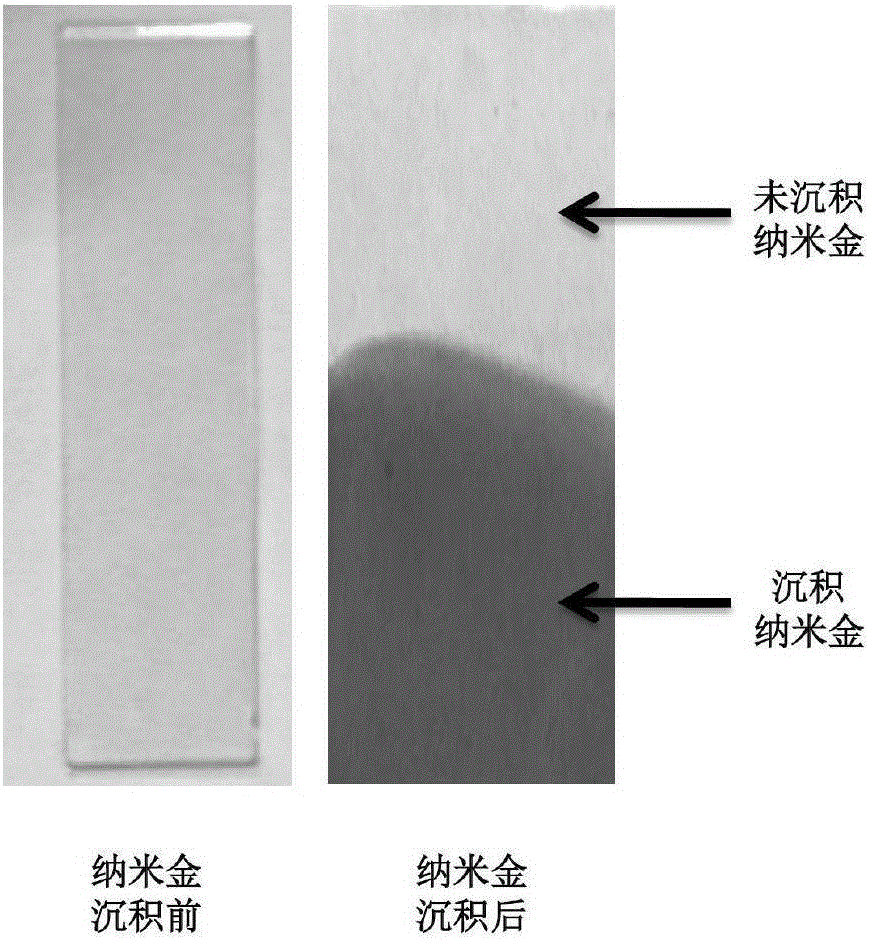

[0025] (4) Ultrasonic clean the ITO glass with absolute ethanol, and then place it in a UV ozone cleaner for 30 minutes, then place the cleaned ITO with the conductive surface facing up, soak it in 1 mg / mL PDDA solution for 5 minutes, and take it out , washed with distilled water several times in a small amount, an...

Embodiment 2

[0033] (1) Pour PDMS liquid A (monomer) and liquid B (initiator) into a beaker at a mass ratio of 10:1, stir with a glass rod for 5 minutes, and then pour it into the above-mentioned petri dish with a silicon wafer. The culture dish was placed in a concentrated desiccator, evacuated with a diaphragm vacuum pump for 1.5 hours to remove air bubbles in PDMS, and then placed in a vacuum oven at 80°C for 1 hour to solidify. After it cooled naturally, the PDMS was gently peeled off from the silicon wafer template, cut into small pieces with a cutting machine, and then punched holes in the corresponding parts with a manual chip puncher for experimental use.

[0034] (2) Ultrasonic clean the ITO glass with absolute ethanol, then place it in a UV ozone cleaner for 30 minutes, then place the cleaned ITO with the conductive surface facing up, soak it in 10mg / mL PDDA solution for 5min, take it out , washed with distilled water several times in a small amount, and then blown dry with nitro...

Embodiment 3

[0038] (1) Pour PDMS liquid A (monomer) and liquid B (initiator) into a beaker at a mass ratio of 10:1, stir with a glass rod for 5 minutes, and then pour it into the above-mentioned petri dish with a silicon wafer. The culture dish was placed in a concentrated desiccator, evacuated with a diaphragm vacuum pump for 1.5 hours to remove air bubbles in PDMS, and then placed in a vacuum oven at 80°C for 1 hour to solidify. After it cooled naturally, the PDMS was gently peeled off from the silicon wafer template, cut into small pieces with a cutting machine, and then punched holes in the corresponding parts with a manual chip puncher for experimental use.

[0039] (2) Ultrasonic clean the ITO glass with absolute ethanol, then place it in a UV ozone cleaner for 30 minutes, then place the cleaned ITO with the conductive surface facing up, soak it in 10mg / mL PDDA solution for 5min, take it out , washed with distilled water several times in a small amount, and then blown dry with nitro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com