A high-frequency horizontal double-diffused oxide semiconductor device and its manufacturing method

An oxide semiconductor and double-diffusion technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc. The effects of grid defects, reduced on-resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

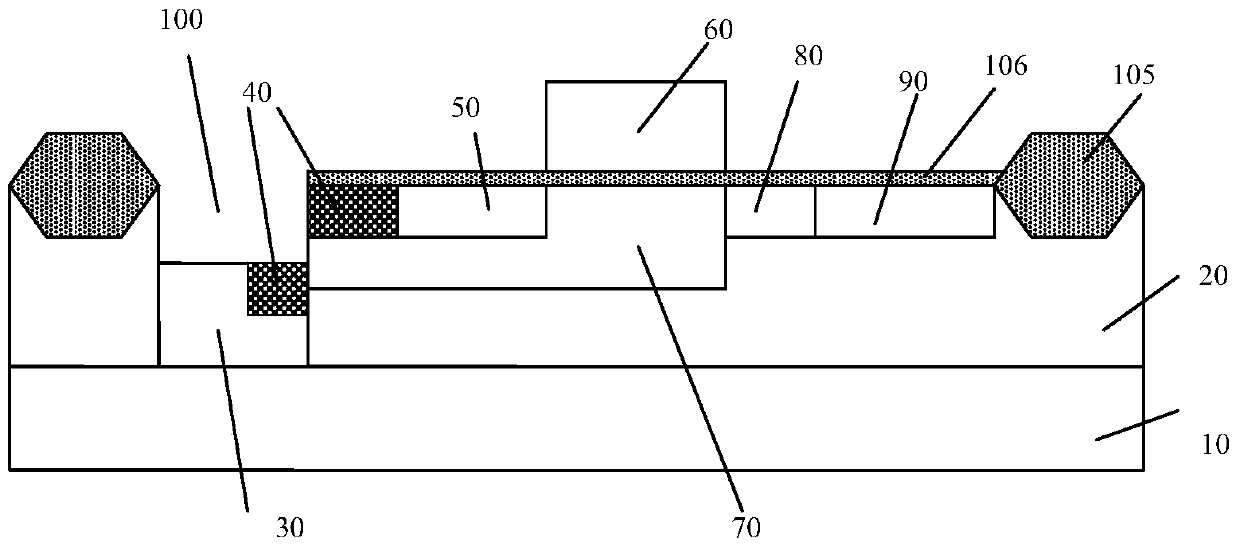

[0033] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

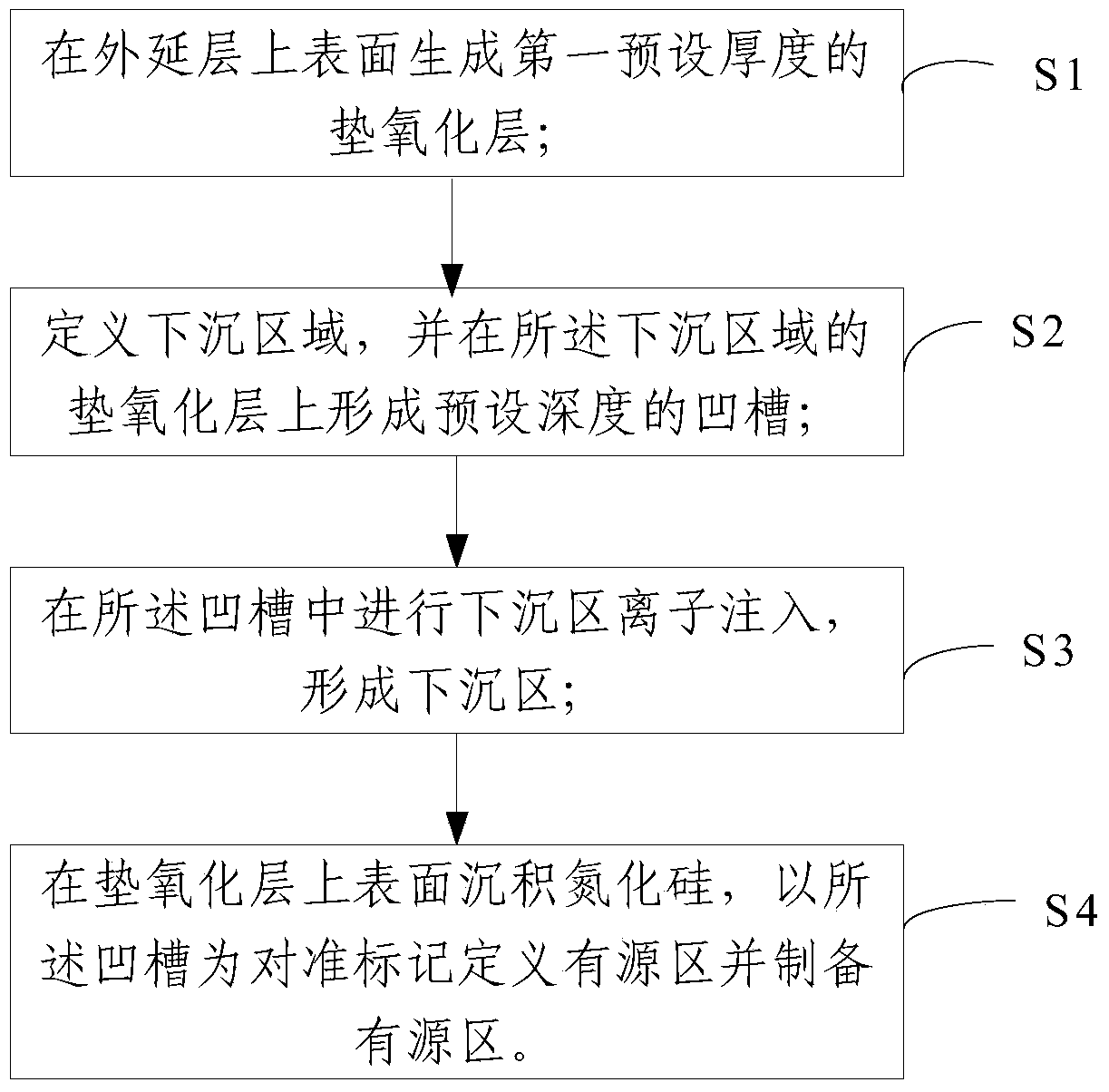

[0034] figure 2 A flow chart of the method of fabricating an RF LDMOS device of the present invention is shown.

[0035] refer to figure 2 , the concrete process of the method for manufacturing RF LDMOS device of the present invention is as follows:

[0036] S1, generating a pad oxide layer with a first preset thickness on the upper surface of the epitaxial layer;

[0037] The pad oxide layer in this embodiment is formed by thermally oxidizing the upper surface of the epitaxial layer to form a pad oxide layer of the first preset thickness on the upper surface of the epitaxial layer; or using a chemical vapor deposition process on the epitaxial layer A pad oxide layer with a first preset thickness is deposited on the upper surface of the pad oxide layer, and the thickness of the generated pad oxide layer is 1500-2000 angstroms.

[0038] S2. A first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com