A kind of nano flake ni (oh) Catalyst and its preparation method and application

A nanosheet-like, catalyst technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

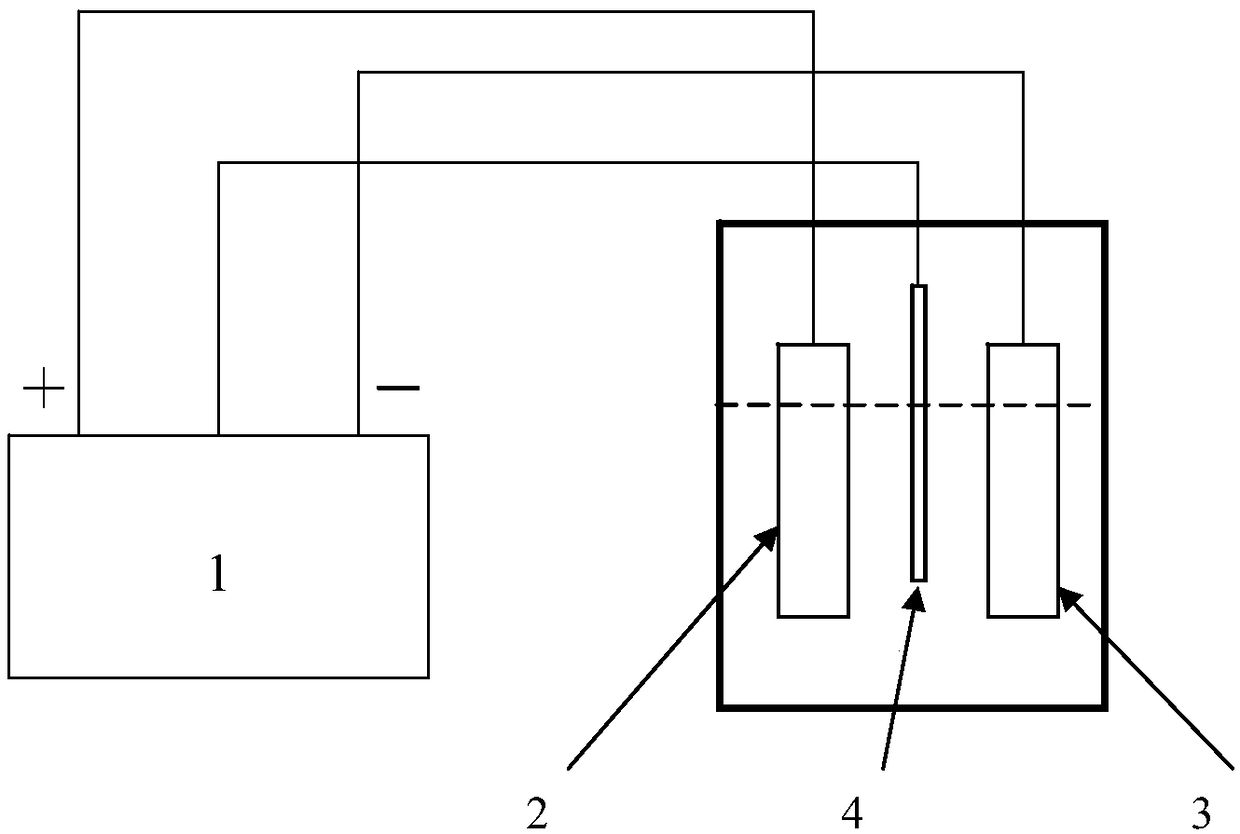

[0042] The nano flake Ni(OH) of this implementation 2 The preparation method of catalyst comprises the following steps:

[0043] (1) Use a pure nickel sheet with a thickness of 0.2mm and a purity of 96.6% as the base metal, cut it into a rectangle of 3.5cm × 0.5cm, and the upper part with a length of 1.5cm is the clamping part, which is used to connect with the Connection, the lower part with a length of 2cm is the actual use part, which is immersed in the electrolyte to participate in the anodic oxidation reaction.

[0044] (2) Use acetone and alcohol to remove the oil stain and oxide layer on the surface of the nickel sheet in an ultrasonic environment. The amount of acetone and alcohol is just enough to cover the nickel sheet sample. First, ultrasonically clean it in the acetone solution for 10 minutes, and then put it in the alcohol solution. Ultrasonic cleaning for 10 minutes; after ultrasonic degreasing, rinse with deionized water and dry.

[0045] (3) Add 1mol L to th...

Embodiment 2

[0077] The nano flake Ni(OH) of this implementation 2 The preparation method of catalyst comprises the following steps:

[0078] (1) Use nickel foam with a thickness of 0.5mm and a purity of 96.6% as the base metal, cut it into a rectangle of 3.5cm × 0.5cm, and the upper part with a length of 1.5cm is the clamping part, which is used to connect with the fixture , the lower part with a length of 2cm is the actual use part, which is immersed in the electrolyte to participate in the anodic oxidation reaction.

[0079] (2) Use acetone and alcohol to remove the oil stain and oxide layer on the surface of the nickel foam in an ultrasonic environment. The amount of acetone and alcohol is just enough to cover the nickel sheet sample. First, ultrasonically clean it in the acetone solution for 10 minutes, and then put it in the alcohol solution. Ultrasonic cleaning for 10 minutes; after ultrasonic degreasing, rinse with deionized water and dry.

[0080] (3) Add 0.5mol L to the contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com