Micro-strip open loop filter

A filter and microstrip technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of high resonance frequency, large size, high order, etc., to reduce the resonance frequency, extend the current path, and extend the current path Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

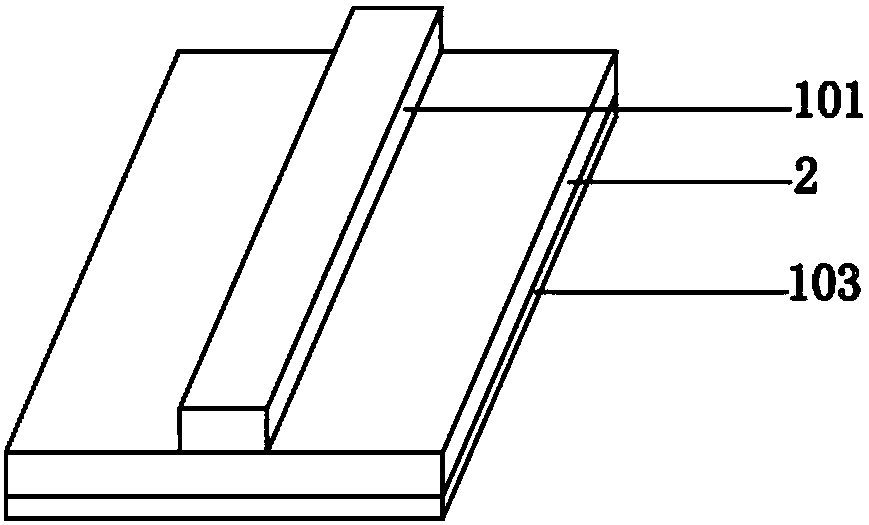

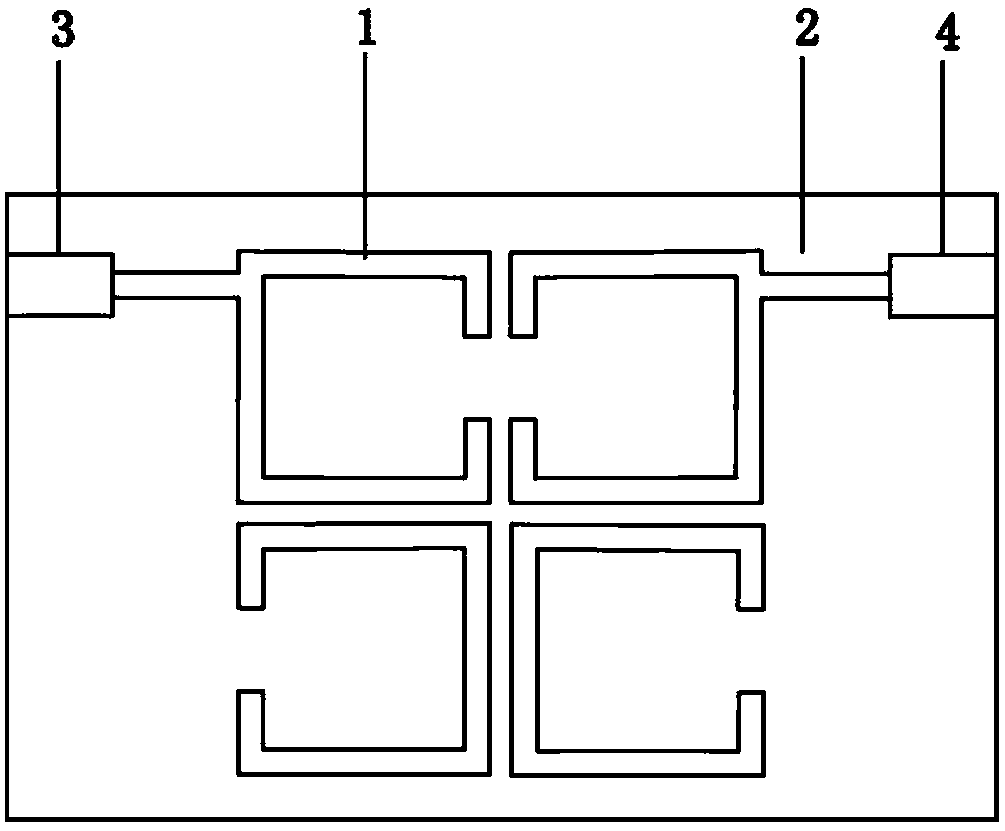

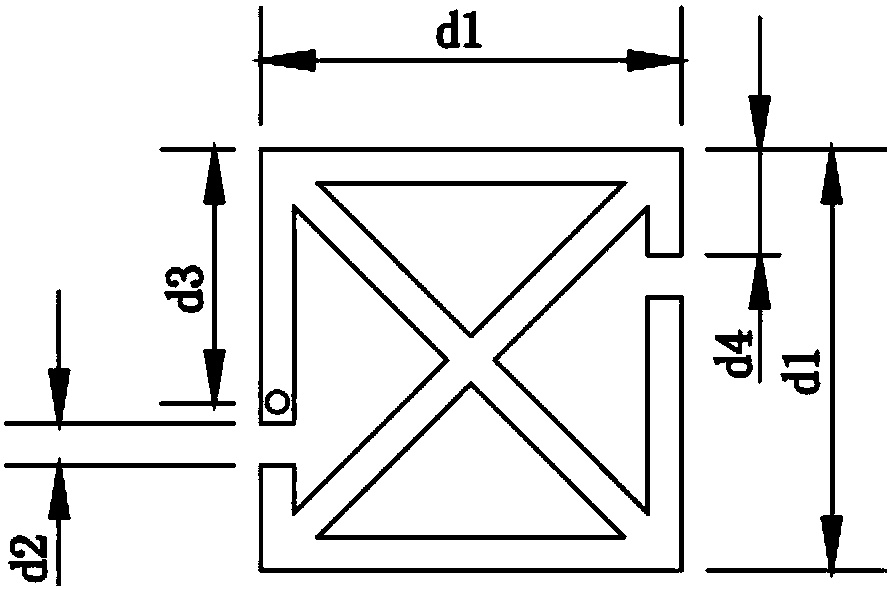

[0026] Such as Figure 5 As shown, the microstrip open-loop filter includes a ground plane 103 located on the back of the dielectric substrate 2 and an input terminal 3, an input terminal microstrip line 5, an output terminal 4, an output terminal microstrip line 6 and a Two square resonator groups, each resonator group includes two sub-resonators 1, and the four sub-resonators 1 are all open-loop structures with the same size and structure. The two sub-resonators 1 in the first resonator group in the first row are arranged in a straight line with the input end 3 and the output end 4 and are symmetrically distributed with the mid-perpendicular line of the line as the axis of symmetry, and the two resonator groups are connected to each other. Parallel and the sub-resonators 1 in each resonator group are distributed symmetrically with the mid-perpendicular line as the axis of symmetry. The output terminal 3 is coupled and connected to the sub-resonator 1 close to the input term...

Embodiment 2

[0029] Such as Image 6As shown, compared with the microstrip open-loop filter of Embodiment 1, the main difference is that the microstrip open-loop filter of this embodiment includes two resonator groups, wherein the first resonator group includes four sub-resonators 1. The second resonator group includes two sub-resonators 1 .

Embodiment 3

[0031] Such as Figure 7 As shown, compared with the microstrip open-loop filter of Embodiment 1, the main difference is that the microstrip open-loop filter of this embodiment includes three resonator groups, wherein the first resonator group includes two sub-resonators 1. The second resonator group includes four sub-resonators 1, and the third resonator group includes two sub-resonators 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com