Method for preparing artificial nerve conduit based on 3D printing and artificial nerve conduit

An artificial nerve and 3D printing technology, applied in the field of artificial nerve conduits, can solve the problems of restricting clinical application of autologous nerve transplantation, and achieve the effect of facilitating cell proliferation and growth, long degradation cycle, and fast degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

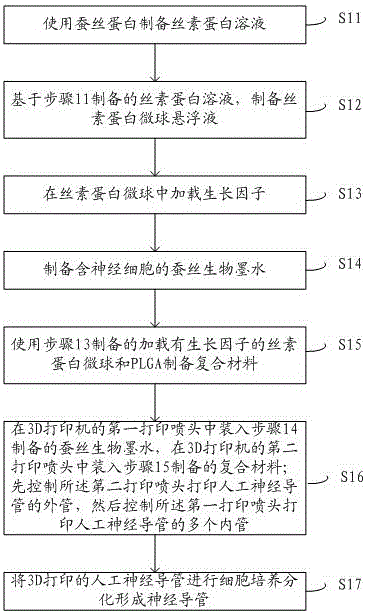

Method used

Image

Examples

Embodiment 1

[0053] 1. Preparation of silk fibroin solution: In order to remove the sericin in silk fibroin, place silk fibroin in 4.24g / L sodium carbonate solution, boil it for 20 minutes, wash it with deionized water and dry it . Dissolve silk fibroin with a 9.3mol / L lithium bromide aqueous solution, dialyze the resulting solution, remove the lithium bromide in the solution by ion exchange, and obtain fresh regenerated silk fibroin aqueous solution after centrifugation. Place the solution in an oven and slowly concentrate to the silk fibroin solution The concentration is 15%. Store at 4°C.

[0054] 2. Preparation of silk fibroin microsphere suspension: mix the above silk fibroin solution with 10% PEG solution, add emulsifier Tween-20 dropwise while stirring, and the volume ratio is 2:1, then mix The solution was placed in the refrigerator to freeze for 48 hours, and after taking it out, it was melted at room temperature to obtain a milky white solution. The solution was centrifuged at a s...

Embodiment 2

[0062] 1. Preparation of silk fibroin solution: In order to remove the sericin in silk fibroin, place silk fibroin in 4.24g / L sodium carbonate solution, boil it for 30 minutes, wash it with deionized water and dry it . Dissolve silk fibroin with a 9.3mol / L lithium bromide aqueous solution, dialyze the resulting solution, remove the lithium bromide in the solution by ion exchange, and obtain fresh regenerated silk fibroin aqueous solution after centrifugation. Place the solution in an oven and slowly concentrate to the silk fibroin solution The concentration is 20%. Store at 4°C.

[0063] 2. Preparation of silk fibroin microsphere suspension: mix the above silk fibroin solution with 10% PEG solution, add emulsifier Tween-40 dropwise while stirring, and the volume ratio is 2:1, then mix The solution was placed in the refrigerator to freeze for 48 hours, and after taking it out, it melted at room temperature to obtain a milky white solution. The solution was centrifuged at a speed...

Embodiment 3

[0071] 1. Preparation of silk fibroin solution: In order to remove the sericin in silk fibroin, place silk fibroin in 4.24g / L sodium carbonate solution, boil it for 50 minutes, wash it with deionized water and dry it . Dissolve silk fibroin with a 9.3mol / L lithium bromide aqueous solution, dialyze the resulting solution, remove the lithium bromide in the solution by ion exchange, and obtain fresh regenerated silk fibroin aqueous solution after centrifugation. Place the solution in an oven and slowly concentrate to the silk fibroin solution The concentration is 25%. Store at 4°C.

[0072] 2. Preparation of silk fibroin microsphere suspension: mix the above silk fibroin solution with 20% PEG solution, add emulsifier Tween-60 dropwise while stirring, the volume ratio is 2:1, and then mix The solution was placed in the refrigerator to freeze for 48 hours, and after taking it out, it melted at room temperature to obtain a milky white solution. The solution was centrifuged at a speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com