Laser engraving technique of decorative sheet

A technology of laser engraving and laser engraving machine, which is applied in the direction of decorative art and the process for producing decorative surface effects, etc. It can solve the problems of long development time, weeks to one month, low processing efficiency, etc., and achieve uniform and detailed patterns and characters Natural, good application effect, stronger three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

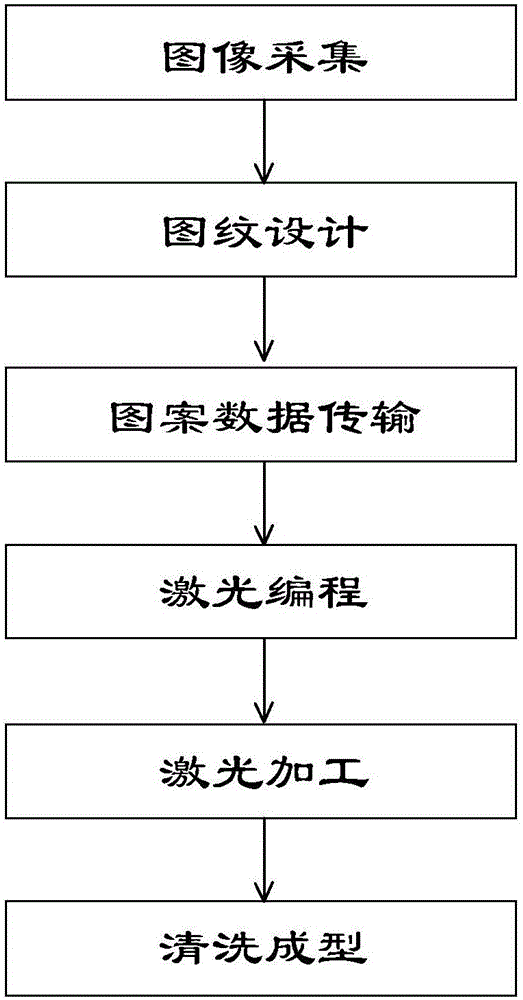

[0020] Such as figure 1 As shown, a decorative sheet laser engraving process has a short pattern development cycle, low input cost, and the processed product has smooth corners and a stronger three-dimensional effect.

[0021] This laser engraving process, during concrete implementation, comprises the following steps:

[0022] A1. First collect the approximate image model to be designed, use a scanner to scan the collected pattern, and transfer it to the computer for storage;

[0023] A2. Redesign based on the collected pattern, use CORELDRAW or PHOTOSHOP graphics software on the computer to take the scanned pattern as the prototype, modify and adjust, and add new ideas to design the required new pattern;

[0024] A3. Transfer the newly designed pattern data information to the storage unit of the laser engraving machine control system for storage;

[0025] A4. Edit the driver program according to the pattern data information stored in the laser engraving machine control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com