Foamed ceramic filter and making method thereof

A technology of foam ceramics and filters, which is applied in the direction of membrane filters, ceramic products, chemical instruments and methods, etc., can solve the problems of high price and unsatisfactory filtration of molten steel, and achieve good porosity, good filtration and adsorption capacity , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

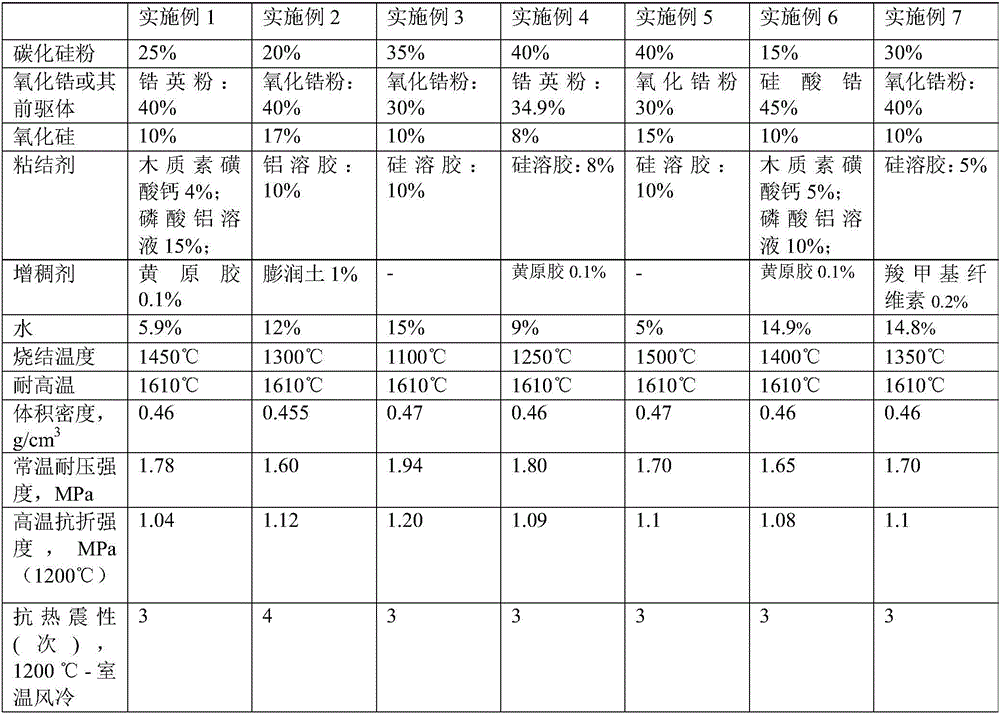

Embodiment 1

[0142] Silicon carbide powder: 25%; zircon powder: 40%; silicon oxide: 10%; calcium lignosulfonate: 4%; aluminum phosphate solution (containing aluminum phosphate 7.5%) 15%. The above-mentioned materials are all commercially available materials, and the stated ratios are all percentages by weight. In the above powder, 0.1% xanthan gum and 5.9% water need to be added. Slurry is made by mixing powder and water with a high-efficiency mixer. This slurry is used to coat polyurethane foam. After the foam is coated with the slurry, remove the blocked holes with air, then put it into a microwave drying oven, keep it warm at 100-120°C for 1 hour, put it into a sintering furnace, and then sinter at 1450°C. The polyurethane foam therein is also a commercially available material.

[0143] The size of the filter made according to this formula is 50×50×15mm, and the porosity is 82%. 50kg of molten steel was filtered at 1610°C. As a result, the filter withstood the test conditions and fi...

Embodiment 2

[0146] Silicon carbide powder: 20%; zirconia powder: 40%; silicon oxide: 17%; aluminum sol: 10%. The above-mentioned materials are all commercially available materials, and the stated ratios are all percentages by weight. In the above powder, 1% of bentonite and 12% of water need to be added. Slurry is made by mixing powder and water with a high-efficiency mixer. This slurry is used to coat polyurethane foam. After the foam is coated with the slurry, remove the blocked holes with air, then put it into a hot air drying furnace, keep it warm at 100-120°C for 2 hours, put it into a sintering furnace, and then sinter at 1300°C. The polyurethane foam therein is also a commercially available material.

[0147] The size of the filter made according to this formula is 50×50×15mm, and the porosity is 83%. 50kg of molten steel was filtered at 1610°C. As a result, the filter withstood the test conditions and filtered the molten steel as required.

[0148] The chemical composition of...

Embodiment 3

[0150] Silicon carbide powder: 35%; zirconia powder: 30%; silicon oxide: 10%; silica sol: 10%. The above-mentioned materials are all commercially available materials, and the proportions are all percentages by weight. In the above powder, 15% water needs to be added. Slurry is made by mixing powder and water with a high-efficiency mixer. This slurry is used to coat polyurethane foam. After the foam is coated with the slurry, remove the blocked holes with air, then put it into a hot air drying furnace, keep it warm at 100-120°C for 1 hour, put it into a sintering furnace, and then sinter at 1100°C. The polyurethane foam therein is also a commercially available material.

[0151] The size of the filter made according to this formula is 50×50×15mm, and the porosity is 84%. 50kg of molten steel was filtered at 1610°C. As a result, the filter withstood the test conditions and filtered the molten steel as required.

[0152] The chemical composition of the manufactured filter is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com