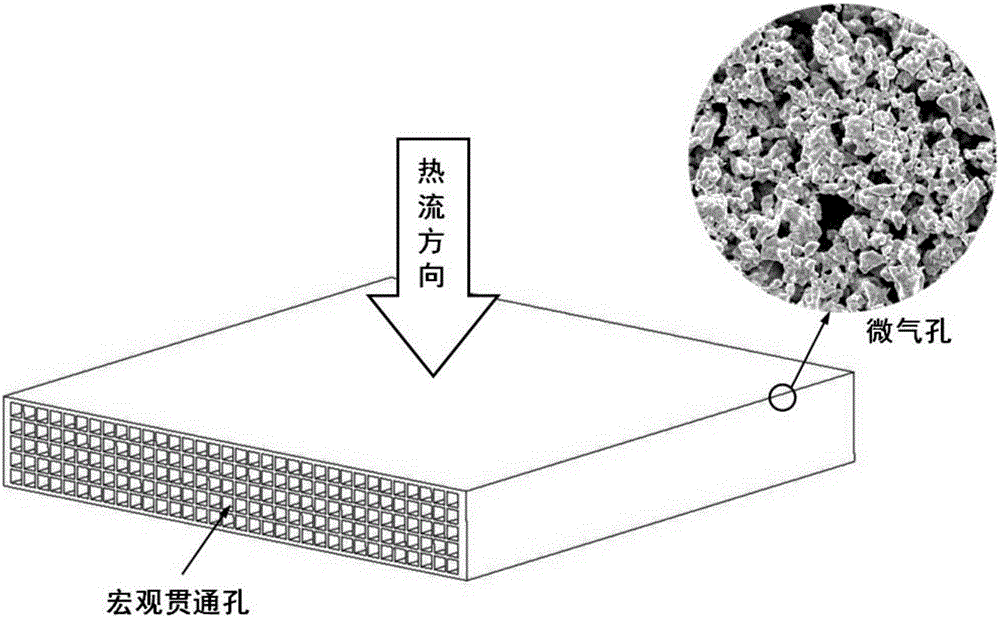

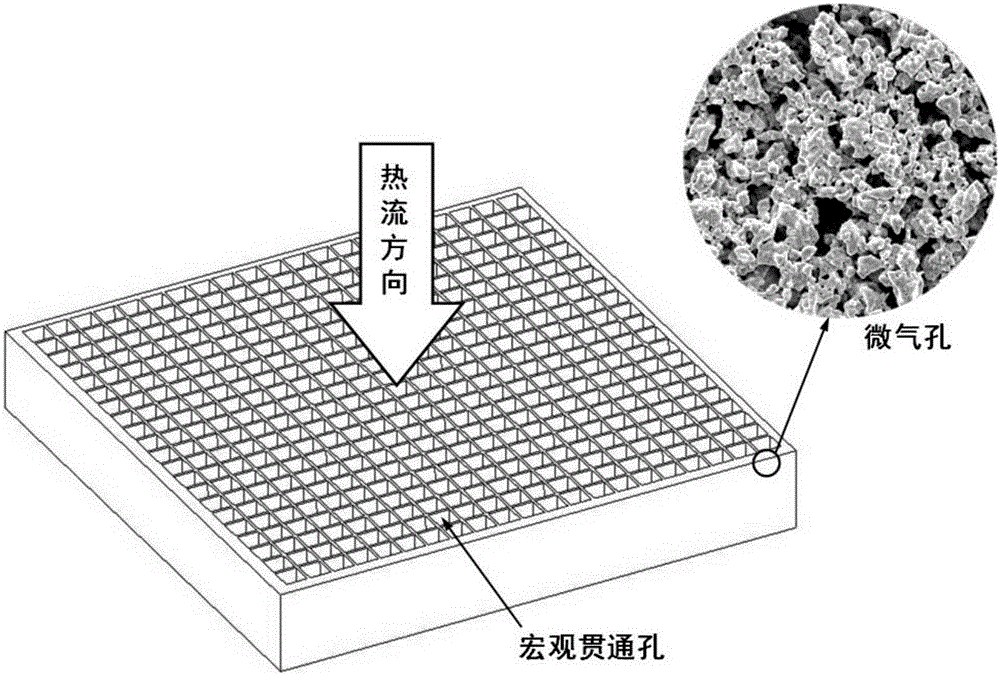

High-temperature-resistant lightweight heat-insulating material with dual pore structure and preparation method thereof

A heat-insulating material and high-temperature-resistant technology, which is applied in home appliances, manufacturing tools, ceramic products, etc., can solve problems such as energy-saving effect, poor thermal shock resistance, poor high-temperature creep resistance, and large volume heat capacity, so as to improve strength and Effects of high temperature creep resistance, thermal conductivity reduction, and thermal shock resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

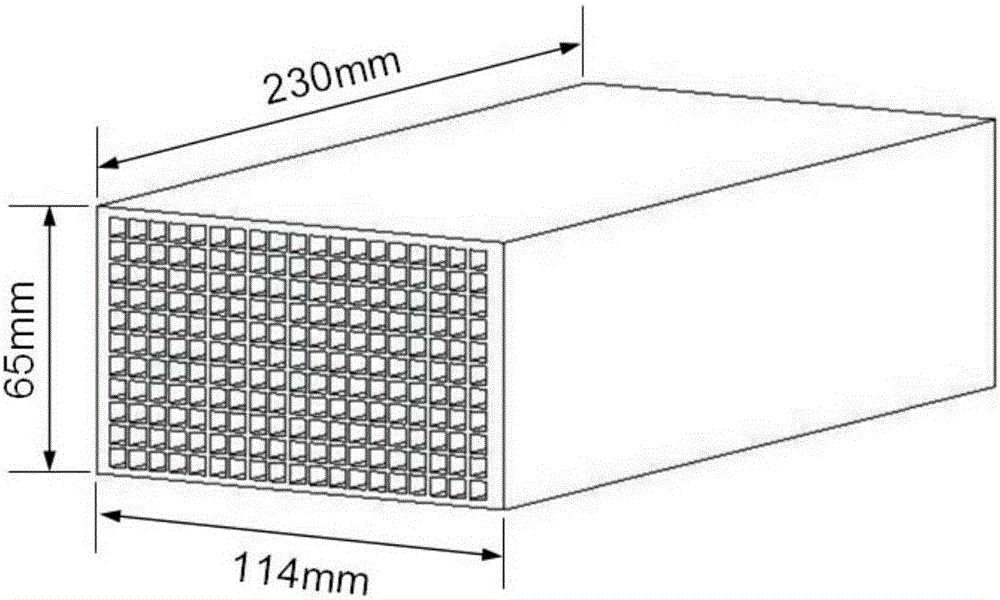

Embodiment 1

[0048] In this example, the mass ratio of alumina, silica, fused mullite, andalusite and Suzhou soil powder is 54:2:30:10:4. The mass ratio of raw material to activated carbon pore former is 100:1.5. The Al / Si ratio of the raw materials in this example is 6.0:1, and the properties of the samples are listed in Table 1. Its bulk density is 1.10, its flexural strength is 12MPa, its thermal conductivity is 0.85W / m K (perpendicular to the through hole) and 2.00W / m K (parallel to the through hole), and its volumetric heat capacity is 59kJ / K m 3 , the creep index is 1.65, and the thermal shock resistance index is 65. The sample in this example uses a standard brick mold during extrusion molding to extrude a green body with width × thickness = 137mm × 78mm, and cut it into a standard brick green body with a length of 277mm. After firing, the length × width × thickness = Standard brick sample of 230mm×114mm×65mm, as attached image 3 shown.

Embodiment 2

[0050] In this example, the mass ratio of alumina, silica, fused mullite, andalusite and Suzhou soil powder is 42:2:30:20:6. The mass ratio of the total raw material to the activated carbon pore-forming agent is 100:1.5. In this example, the raw material Al / Si ratio is 4.2:1. The properties of the samples are listed in Table 1. Its bulk density is 0.95, its flexural strength is 9.8MPa, its thermal conductivity is 0.78W / m·K (perpendicular to the through hole) and 1.88W / m·K (parallel to the through hole), and its volumetric heat capacity is 52kJ / K· m 3 , the creep index is 2.64, and the thermal shock resistance index is 70. The sample in this example uses a flat die during extrusion molding to extrude a green body with width×thickness=578mm×90mm, and cut it into a flat green body with a length of 963mm, and obtain length×width×thickness=800mm after firing ×480mm×75mm flat sample, as attached Figure 4 shown.

Embodiment 3

[0052] In this example, the mass ratio of alumina, silica, fused mullite, kyanite, and Suzhou soil powder raw materials is 66:2:30:20:2. The mass ratio of raw material to activated carbon pore former is 100:1.5. In this example, kyanite is used instead of mullite and andalusite as the main source of silica, and the amount of alumina is more than that in Examples 1 and 2, and the Al / Si ratio in the raw material is 6.8:1. The properties of the samples are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com