Industrial polysulfone resin production process

A technology of polysulfone resin and production process, which is applied in the field of polymer material preparation, can solve the problems of large molecular weight distribution span of polymerized hydrocarbons, no reaction system temperature control treatment, and reduced production efficiency, so as to facilitate the post-treatment of water boiling method and reduce the The risk of pipe clogging and the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

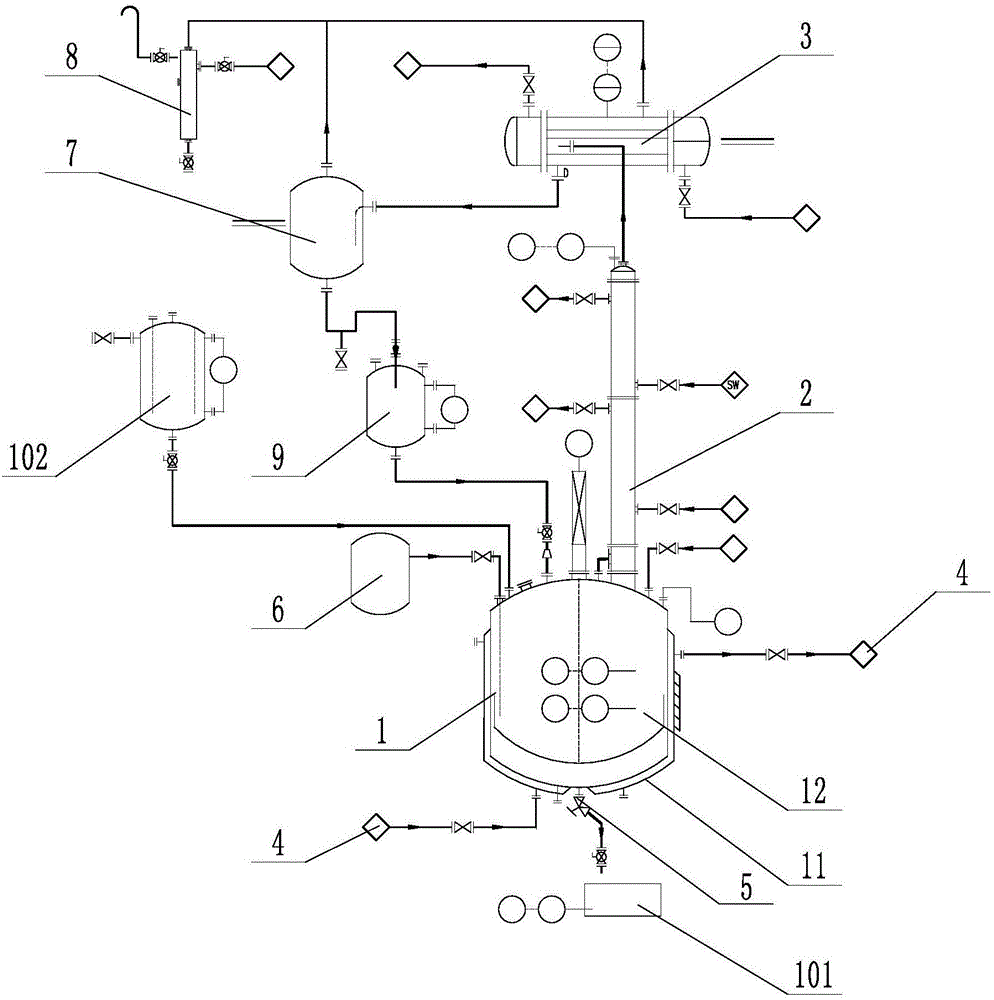

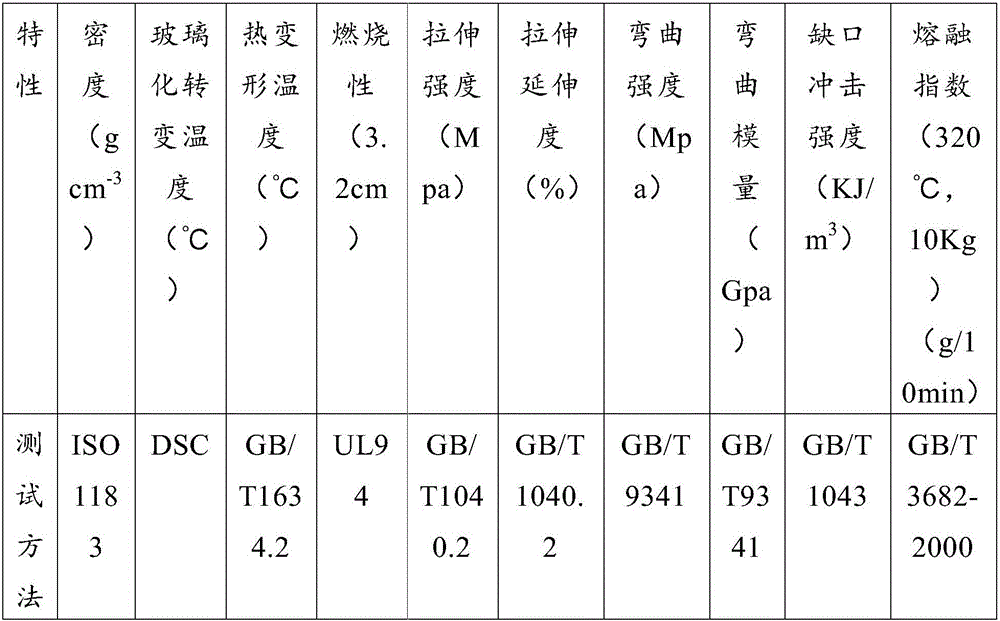

[0043] Embodiment one: a kind of polysulfone resin industrialized production process, comprises the following steps:

[0044] Step 1: Pre-treatment of the polymerization reaction: add the polymerization reaction materials used to prepare the polysulfone resin into the polymerization reaction kettle, start the agitator in the polymerization reaction kettle, pass inert gas into the polymerization reaction kettle, and replace the gas in the gas phase space in the polymerization reaction kettle A high-temperature heat-conducting material is passed into the interlayer of the polymerization reactor, so that the polymerization reaction materials in the polymerization reactor reach the polymerization reaction temperature.

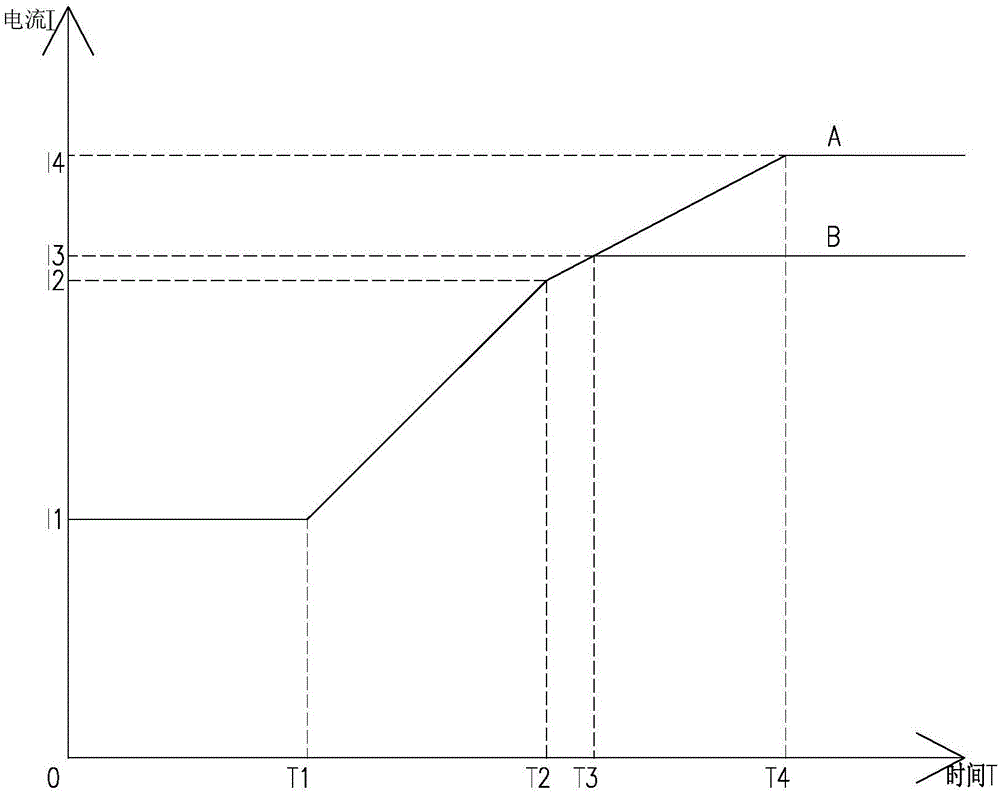

[0045] Step 2: Polymerization reaction: Continuously feed high-temperature heat-conducting materials into the interlayer of the polymerization reactor, detect the viscosity in the polymerization reactor through the viscosity detection device, and detect the temperat...

Embodiment 2

[0047] Embodiment two: a kind of polysulfone resin industrialized production process, comprises the following steps:

[0048] Step 1: Pre-treatment of the polymerization reaction: add the polymerization reaction material used to prepare the polysulfone resin into the polymerization reaction tank, the polymerization reaction material is the polymerization reaction material with free radicals, start the agitator in the polymerization tank, and start the polymerization reaction Inert gas is introduced into the reactor to replace the gas phase space gas in the polymerization reactor, and a high-temperature heat-conducting material is introduced into the interlayer of the polymerization reactor to make the polymerization reaction materials in the polymerization reactor reach the polymerization reaction temperature;

[0049] Step 2: Polymerization reaction: Continuously feed high-temperature heat-conducting materials into the interlayer of the polymerization reactor, detect the visco...

Embodiment 3

[0051] Embodiment three: a kind of polysulfone resin industrialized production process, comprises the following steps:

[0052] Step 1: Pre-treatment of the polymerization reaction: add the polymerization reaction material used to prepare polysulfone resin into the polymerization reactor, the polymerization reaction material is a polymerization reaction material with free radicals, which includes bisphenol A polysulfone, open The agitator in the polymerization kettle feeds inert gas into the polymerization kettle to replace the gas phase space gas in the polymerization kettle, and feeds high-temperature heat-conducting materials into the interlayer of the polymerization kettle to make the polymerization reaction materials in the polymerization reaction kettle reach the polymerization reaction temperature ; The inert gas is nitrogen or carbon dioxide.

[0053] Step 2: Polymerization reaction: Continuously feed high-temperature heat-conducting materials into the interlayer of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com