Method for preparing apricot extract aroma enhancement component for cigarettes

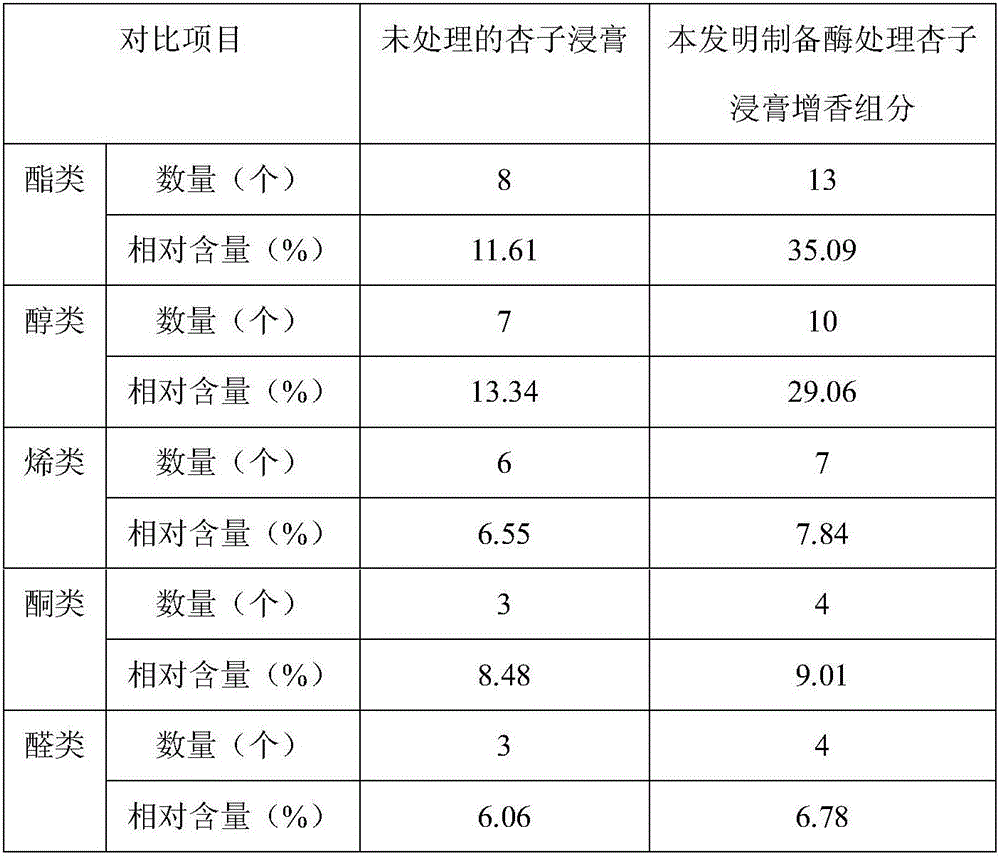

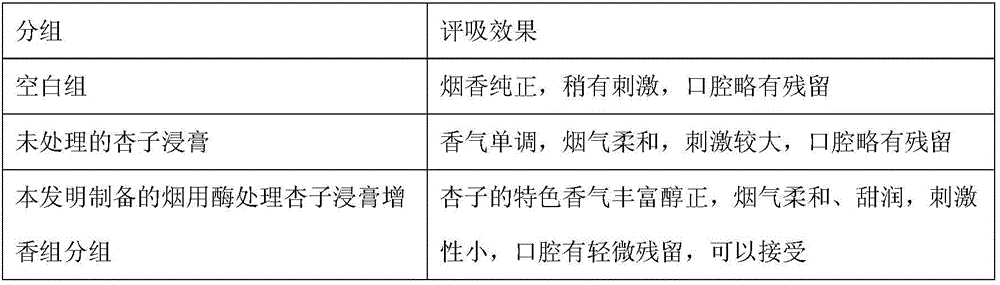

A technology of apricot and extract, which is applied in the field of preparation of flavoring components of apricot extract for tobacco, can solve the problems of insignificant smoking quality, insufficient improvement of tobacco, and loss of aroma substances, etc., and achieve rich and rich aroma. Tobacco aroma, reducing irritation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Fresh apricots are cleaned, peeled, pitted, drained, and squeezed with a juicer to obtain apricot juice;

[0020] (2) Add β-glucosidase that accounts for 1.5‰ of the total amount of apricot juice in the apricot juice gained in step (1), after enzymolysis 60min under the condition of 45 ℃, be placed in boiling water to kill enzyme 3min, and rapidly Cool to room temperature to obtain apricot juice after enzymolysis;

[0021] (3) 95% ethanol of 4 times of weight is added in the apricot juice after enzymolysis, after standing for 24 hours, take supernatant and concentrate under reduced pressure at 50 ℃ to 10% of supernatant weight before concentration, obtain enzyme processing apricot extract;

[0022] (4) Add 4 times the weight of activated AB-8 macroporous resin and 20 times the weight of ultrapure water to the apricot extract, fully stir for 30 minutes, naturally settle for 48 hours, discard the supernatant, and wash with ultrapure water Resin twice, obtains the re...

Embodiment 2

[0025] (1) Fresh apricots are cleaned, peeled, pitted, drained, and squeezed with a juicer to obtain apricot juice;

[0026] (2) Add α-L-rhamnosidase, which accounts for 2.0‰ of the total amount of apricot juice, to the apricot juice obtained in step (1), and after enzymolysis at 30°C for 75 minutes, place in boiling water to inactivate the enzyme for 3 minutes , and rapidly cooled to room temperature to obtain apricot juice after enzymolysis;

[0027] (3) Add 5 times the weight of 95% ethanol to the apricot juice after enzymolysis, and after standing for 24 hours, take the supernatant and concentrate under reduced pressure at 60°C to 5% of the weight of the supernatant before concentration to obtain Enzyme treatment of apricot extract;

[0028] (4) Add 5 times of weight of activated HP-20 macroporous resin and 25 times of weight of ultrapure water to the apricot extract, fully stir for 30min, settle naturally for 48h, discard the supernatant, and wash with ultrapure water R...

Embodiment 3

[0031] (1) Fresh apricots are cleaned, peeled, pitted, drained, and squeezed with a juicer to obtain apricot juice;

[0032] (2) Add β-glucosidase accounting for 1.0‰ of the total amount of apricot juice to apricot juice. After enzymolysis at 45°C for 70 minutes, place in boiling water to inactivate the enzyme for 3 minutes, and rapidly cool to room temperature to obtain the enzymolysis apricot juice;

[0033] (3) Add 4 times the weight of 95% ethanol to the apricot juice after enzymolysis, and after standing for 24 hours, take the supernatant and concentrate under reduced pressure at 50°C to 15% of the weight of the supernatant before concentration to obtain the enzyme processing apricot extract;

[0034] (4) Add 5 times the weight of activated DM-301 macroporous resin and 25 times the weight of ultrapure water to the apricot extract, fully stir for 30 minutes, settle naturally for 48 hours, discard the supernatant, and wash with ultrapure water Resin twice, obtains the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com