Steelmaking method for alloying by adding chrome ore to vacuum environment and top-blowing powder spraying gun

A vacuum environment and alloying technology, applied in the field of alloy steel refining, can solve the problems of increasing the amount of slag and inclusions, poor stirring conditions, etc., and achieve the effects of reduced smelting costs, improved cleanliness of molten steel, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment is applied to a 120-ton vacuum alloying furnace, which is equipped with a vacuum hopper, which is in the form of a double bell valve, and the volume of the hopper is 2m 3 , the volume of the lower hopper is 2m 3 The chrome ore is made of broken Turkish lump ore, the chrome ore grade is 42%, the carbonaceous reducing agent is selected from coke grains, and the particle size range of the chromium ore and carbonaceous reducing agent is 5mm~10mm. GCr15 with a chromium content requirement of 1.3%~1.65% was used as the test steel.

[0027] The specific smelting operation process is as follows: heat the temperature of molten steel to 1650°C in the LF refining furnace, hoist the ladle to the vacuum alloying station, measure the temperature and take samples and place them in the vacuum device, connect the air blowing brick at the bottom of the ladle to the argon blowing pipe , the bottom blowing argon flow rate is set to 100L / min; start the vacuum pump system to...

Embodiment 2

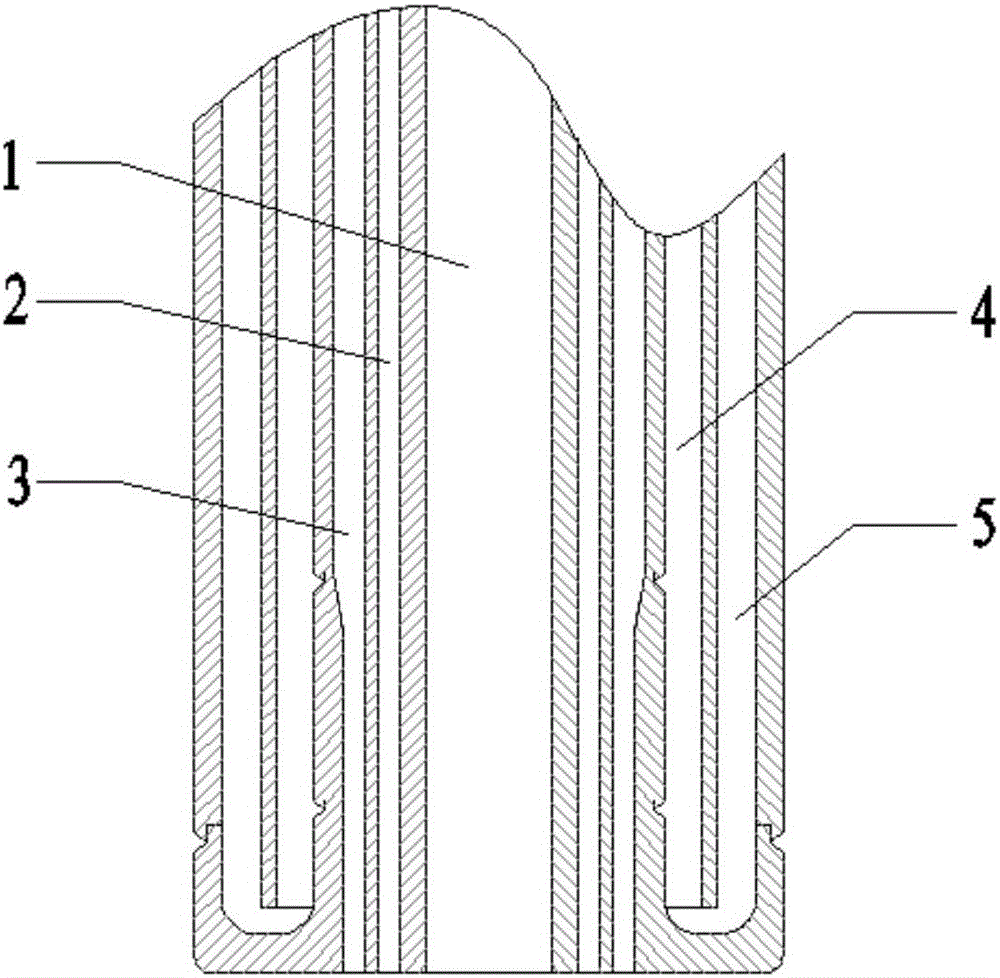

[0030] This embodiment is applied to a 150-ton vacuum alloying furnace. The vacuum alloying furnace is equipped with a top-blowing powder spraying gun. A high-pressure wear-resistant rubber hose is used to connect the powder outlet of the powder spraying equipment with the top-blowing powder spraying gun. The central powder spraying pipe 1 of the gun is made of wear-resistant stainless steel, and the size is mm, the oxygen injection pipe 2 is a stainless steel pipe, the size is , the gas injection pipe 3 is a stainless steel pipe with a size of ; The chrome ore is selected from finely ground South African fine powder, the grade of chrome ore powder is 42%, the carbonaceous reducing agent is selected from anthracite coal powder, the particle size range of chromium ore powder and carbonaceous reducing agent is 0.5~1.0mm, and argon is used as Powder carrier gas. 20CrMnTi with a chromium content of 0.8% to 1.1% was used as the test steel.

[0031] The specific smelting opera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com