A corrosion-resistant hinge

A corrosion-resistant, hinged technology, applied in the field of alloy material processing, can solve the problems of low strength and corrosion resistance, general performance, etc., and achieve the effect of improving corrosion resistance, improving corrosion resistance, improving surface hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

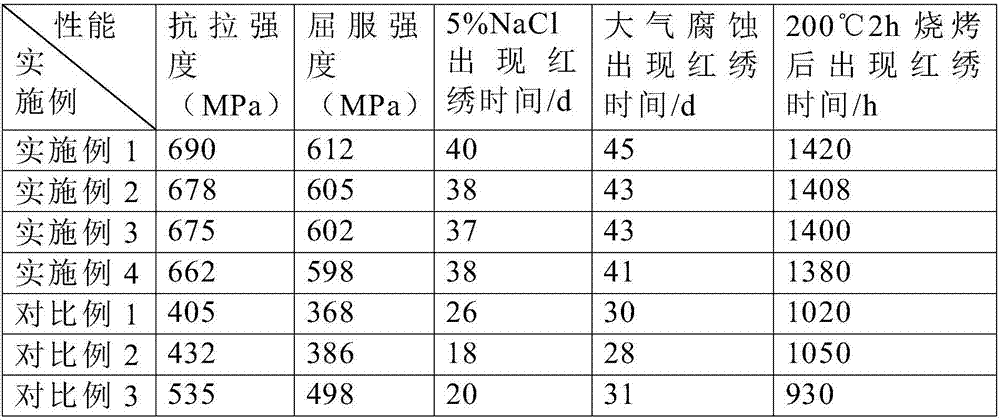

Examples

Embodiment 1

[0030] Raw material steelmaking: according to the composition elements and mass percentage of the alloy steel used in the hinge: C: 0.12%, Cr: 1.5%, Si: 0.16%, Mn: 1.0%, Al: 0.04%, N: 0.012%, Ti: 0.16 %, S: 0.015%, V: 0.012%, P≤0.015%, the balance is Fe and unavoidable impurities; the raw materials are smelted into molten steel, and the molten steel is vacuum smelted, poured, rolled into steel plates, and the steel plates are processed into shapes , to get the hinge blank.

[0031] The hinge blank was cryogenically treated at -150°C for 1.2h, and then the temperature was raised to 240°C at a rate of 4°C / min for low-temperature tempering treatment for 135min to obtain a hinge semi-finished product.

[0032] The hinge semi-finished product was treated in the electroplating solution at 42°C for 40 minutes. The composition of the electroplating solution was: zinc ions 20g / L, nickel ions 2.4g / L, sodium hydroxide 180g / L, tetraethylenepentamine 12g / L, ethyleneimine 10ml / L, citric ac...

Embodiment 2

[0034] Raw material steelmaking: according to the composition elements and mass percentage of the alloy steel used in the hinge: C: 0.14%, Cr: 1.45%, Si: 0.18%, Mn: 1.05%, Al: 0.042%, N: 0.01%, Ti: 0.20 %, S: 0.018%, V: 0.10%, P≤0.015%, the balance is Fe and unavoidable impurities; the raw materials are smelted into molten steel, and the molten steel is vacuum smelted, poured, rolled into steel plates, and the steel plates are processed into shapes , to get the hinge blank.

[0035] The hinge blank was cryogenically treated at -160°C for 1.4h, and then heated to 238°C at a rate of 3.8°C / min for low-temperature tempering treatment for 140min to obtain a hinge semi-finished product.

[0036] Treat the hinge semi-finished product in the electroplating solution at 40°C for 45 minutes. The composition of the electroplating solution is: zinc ion 22g / L, nickel ion 2.0g / L, sodium hydroxide 160g / L, tetraethylenepentamine 14g / L, ethyleneimine 10ml / L, citric acid 5.2g / L, potassium sodiu...

Embodiment 3

[0038] Raw material steelmaking: according to the composition elements and mass percentage of the alloy steel used in the hinge: C: 0.15%, Cr: 1.4%, Si: 0.20%, Mn: 0.8%, Al: 0.05%, N: 0.015%, Ti: 0.12 %, S: 0.022%, V: 0.08-0.15%, P≤0.015%, the balance is Fe and unavoidable impurities; the raw materials are smelted into molten steel, and the molten steel is vacuum smelted, poured, rolled into steel plates, and the steel plates Processing and molding to obtain hinge blanks.

[0039] The hinge blank was cryogenically treated at -138°C for 1.5h, and then heated to 250°C at a rate of 3°C / min for low-temperature tempering treatment for 120min to obtain a hinge semi-finished product.

[0040] Treat the hinge semi-finished product in the electroplating solution at 45°C for 30 minutes. The composition of the electroplating solution is: zinc ions 15g / L, nickel ions 2.8g / L, sodium hydroxide 150g / L, tetraethylenepentamine 15g / L, ethyleneimine 8ml / L, citric acid 6g / L, potassium sodium tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com