A device and method for recovering waste heat from perforating equipment in a steel pipe plant

A waste heat recovery and steel pipe factory technology, applied in lighting and heating equipment, waste heat treatment, furnaces, etc., can solve the problems of impossible large-scale utilization, and achieve the effects of saving fuel consumption, intense convective heat transfer, and recycling waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

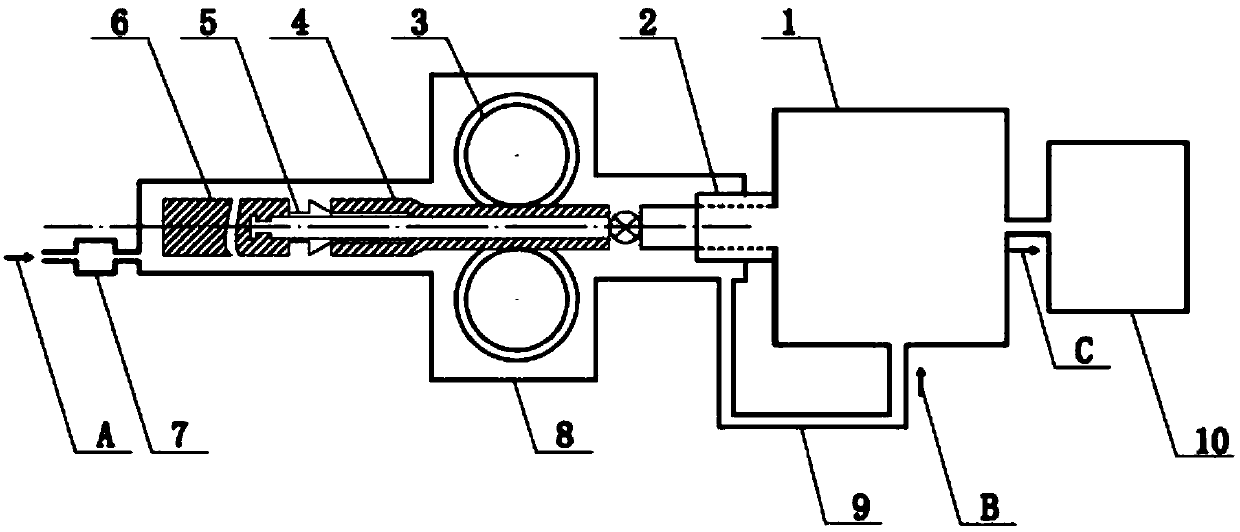

[0025] Such as figure 1 As shown, a device for realizing the method of recovering waste heat from piercing equipment in a steel pipe factory consists of a tube billet heating furnace 1, a piercing pusher 2, a piercing machine rolling rod 3, a piercing machine ejector rod 5, piercing follow-up equipment 6, and a heat preservation device 8. Blower 7, conveying pipeline 9 and waste heat boiler 10; piercing equipment consists of pusher 2, rolling rod 3, ejector rod 5 and follow-up equipment 6; 4 is the tube billet in perforation; perforation pusher 2 and heating The furnace 1 is connected; the heat preservation device 8 is fixed around the perforation equipment around the tube blank along the perforation process. The wall surface of the heat preservation device is preferably 20-40cm away from the tube blank, and the heat preservation device is a small section of 0.5m, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com