Superconductive cavity tuning control system and method based on PLC and touch screen

A superconducting cavity tuning and superconducting cavity technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problem of a single required quantity of resources, complicated wiring of analog devices, and inapplicability to multiple tuner control, etc. problems, to achieve the effect of reasonable utilization of resources, shortened development cycle, and rich types of modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

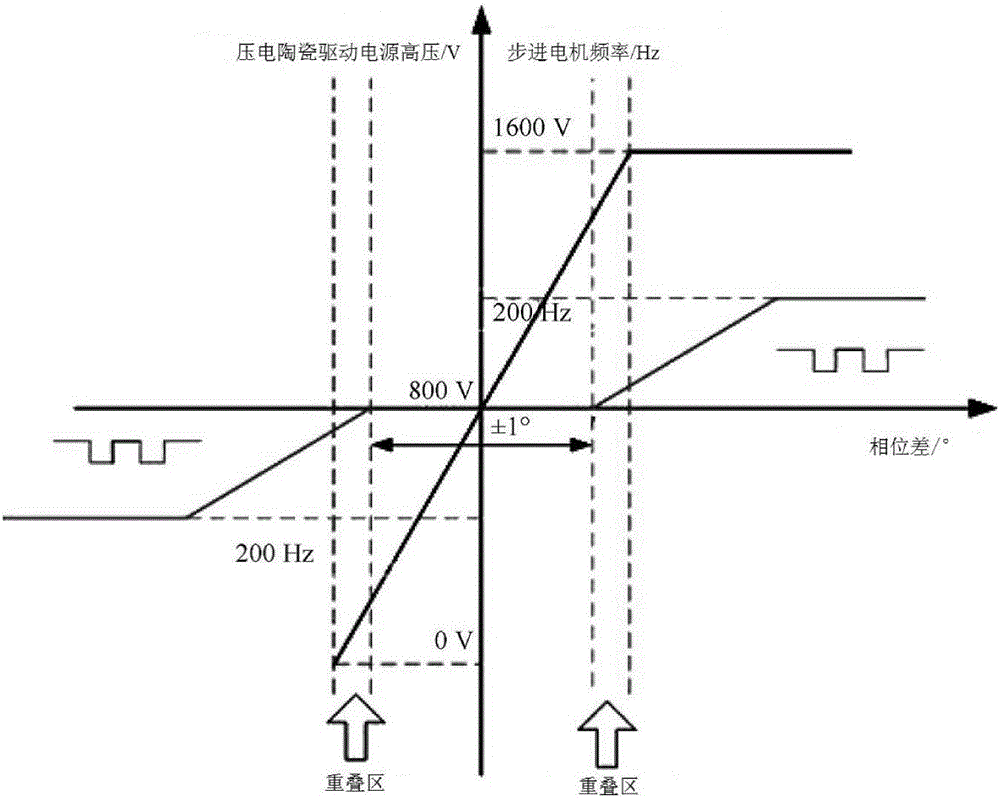

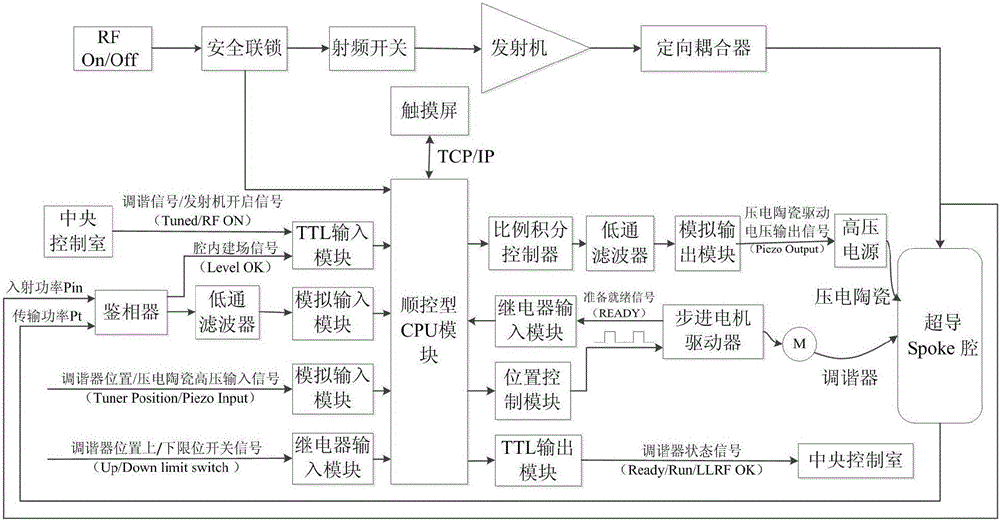

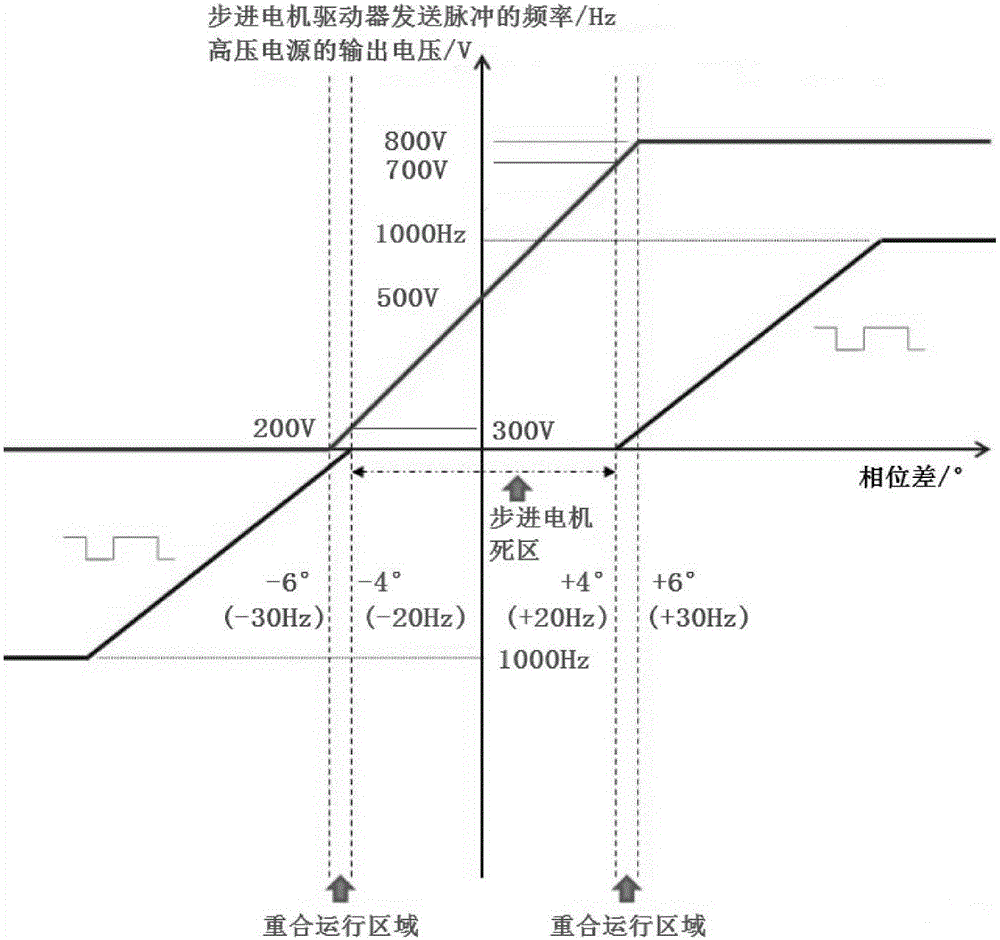

[0061] The superconducting cavity tuning control system uses PLC as the core controller to establish a high-frequency electric field in the superconducting high-frequency cavity, and use the high-frequency phase difference obtained by the phase detector to guide the stepping motor and piezoelectric ceramics to adjust the resonance frequency of the cavity. Feedback control, which forms a man-machine interface with the touch screen, can automatically capture and lock the frequency of the cavity, the phase control accuracy can reach ±0.7°, and the corresponding frequency control accuracy is ±4Hz. The tuning sensitivity of the superconducting cavity is 1.1kHz / um, and the phase sensitivity is 5nm / 1°, the corresponding relationship between phase and frequency is 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com