Method for manufacturing biodegradable shape-memory polymer intravascular stent additive with negative poisson ratio

A technology of memory polymer and negative Poisson's ratio, applied in stents, additive processing, medical science, etc., can solve problems such as restenosis in stents, and achieve the effects of avoiding axial shrinkage, avoiding positioning, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] A negative Poisson's ratio degradable shape memory polymer vascular stent additive manufacturing method, comprising the following steps:

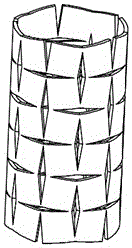

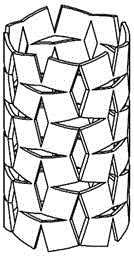

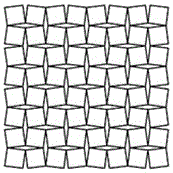

[0057] (1) Based on the rotating quadrilateral structural unit with negative Poisson's ratio effect, design a three-dimensional structural model of vascular stent with negative Poisson's ratio effect in the radial and axial directions, and design a degradable shape memory polymer blood vessel with negative Poisson's ratio The wall thickness of the bracket is 0.2mm, and the diameter is 4mm;

[0058] (2) Input the designed three-dimensional model of the rotating quadrilateral vascular stent into the additive manufacturing system in STL format, and the system control software performs layered slice processing on the three-dimensional model data, and generates corresponding motion trajectory codes for each layer of data ;

[0059] (3) Using micro-syringe droplet jetting free forming technology, using biodegradable shape memory polymer p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com