A regeneration method for adsorbing impurities in zinc sulfate electrowinning waste liquid activated carbon

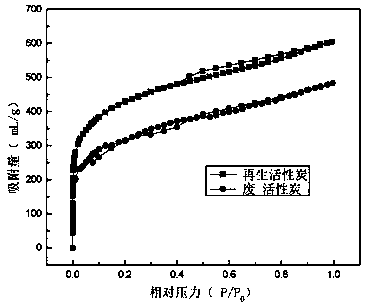

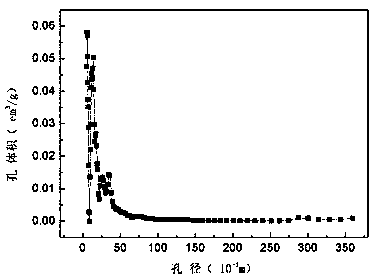

A technology of activated carbon and zinc sulfate, which is applied in the field of comprehensive utilization of resources, can solve the problems of low organic content in waste activated carbon, simplification of methods, and organic residues, etc., and achieve the effect of increasing oxidation ratio, regeneration efficiency, and impurity removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The regeneration method of the impurity activated carbon adsorbing zinc sulfate electrowinning waste liquid, its specific steps are as follows:

[0034] (1) First, add 10g of impurity activated carbon adsorbed to zinc sulfate electrodeposition waste liquid into 1mol / L ethanol solution according to the liquid-solid ratio of 4:1ml / g and mix evenly to form a suspension, then according to the volume ratio of the ethanol solution to 1 : 5 Add pyridine and stir evenly, react in an ultrasonic generator for 30 minutes, then add regeneration solvent I according to the volume ratio of the ethanol solution at 1:3, stir evenly, and react with ultrasonic wave for 20 minutes, vacuum filter, recover the regeneration solvent I from the filtrate, filter residue Activated carbon was obtained after the solid was dried, in which the ultrasonic power was 300W, and the regeneration solvent I was FeSO with a molar ratio of 1:2 4 and H 2 o 2 mixture;

[0035] (2) Dissolve the activated carb...

Embodiment 2

[0040] The regeneration method of the impurity activated carbon adsorbing zinc sulfate electrowinning waste liquid, its specific steps are as follows:

[0041] (1) First, add 10g of impurity activated carbon adsorbed to zinc sulfate electrodeposition waste liquid into 1mol / L ethanol solution according to the liquid-solid ratio of 5:1ml / g and mix evenly to form a suspension, then according to the volume ratio of the ethanol solution to 1 : 6 Add pyridine and stir evenly, react in an ultrasonic generator for 20 minutes, then add regeneration solvent I according to the volume ratio of the ethanol solution at 1:4, stir evenly, and react with ultrasonic waves for 40 minutes, vacuum filter, recover the regeneration solvent I from the filtrate, filter residue Activated carbon was obtained after the solid was dried, in which the ultrasonic power was 600W, and the regeneration solvent I was FeSO with a molar ratio of 1:2 4 and H 2 o 2 mixture;

[0042] (2) Dissolve the activated car...

Embodiment 3

[0046] The regeneration method of the impurity activated carbon adsorbing zinc sulfate electrowinning waste liquid, its specific steps are as follows:

[0047] (1) First, add 10g of impurity activated carbon adsorbed to zinc sulfate electrodeposition waste liquid into 1mol / L ethanol solution according to the liquid-solid ratio of 3:1ml / g and mix evenly to form a suspension, then according to the volume ratio of the ethanol solution to 1 : 4 Add pyridine and stir evenly, react in an ultrasonic generator for 40 minutes, then add regeneration solvent I according to the volume ratio of the ethanol solution at 1:2, stir evenly, and react with ultrasonic wave for 30 minutes, vacuum filter, recover the regeneration solvent I from the filtrate, filter residue Activated carbon was obtained after the solid was dried, in which the ultrasonic power was 400W, and the regeneration solvent I was FeSO with a molar ratio of 1:2 4 and H 2 o 2 mixture;

[0048] (2) Dissolve the activated carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com