Phosphorus-doped porous graphene, preparation method thereof and method for catalyzing oxidation of benzylamine

A technology of porous graphene and magnesium oxide, applied in chemical instruments and methods, preparation of imino compounds, catalyst activation/preparation, etc., can solve the problems of cumbersome preparation process and long period of porous graphene, and achieve easy mass production, Low cost and effect of increasing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

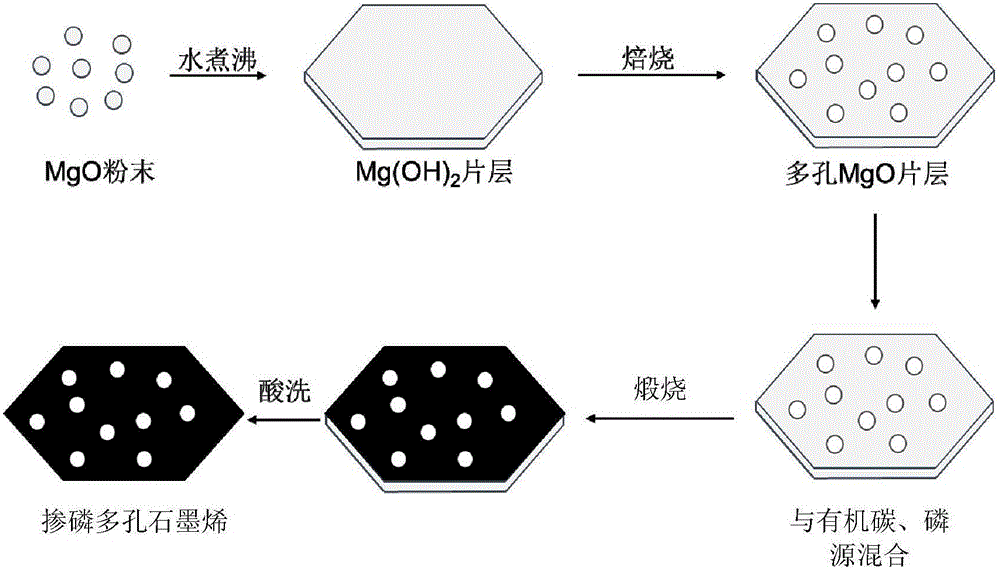

[0053] This embodiment provides a kind of phosphorus-doped porous graphene, which is prepared through the following steps, such as figure 1 Shown:

[0054] (1) Reflux and boil the magnesium oxide powder in water and keep it for 8 hours, cool and filter, and dry at 80°C for 12 hours, then place it in a muffle furnace and raise the temperature to 500°C at a rate of 10°C / min in an air atmosphere. ℃ roasting for 2 hours to obtain porous flake hexagonal magnesium oxide with a specific surface area of 195m 2 / g, the two-dimensional film size is about 300nm;

[0055] (2) Add 0.5g of 4,5-bisdiphenylphosphine-9,9-dimethylxanthene into 30mL of ethanol, and ultrasonically disperse for 0.5 hours, and the ultrasonic power is 80kHz to obtain Source dispersion;

[0056] (3) The porous sheet-shaped hexagonal magnesia that 0.5g step (1) obtains is joined in the dispersion liquid that contains organic carbon, phosphorus source that step (2) obtains, with the rotating speed magnetic stirrin...

Embodiment 2

[0069] This embodiment provides a kind of phosphorus-doped porous graphene, which is prepared through the following steps, such as figure 1 Shown:

[0070] (1) Reflux and boil the magnesium oxide powder in water and keep it for 8 hours, cool, filter and dry at 90°C for 10 hours, then place it in a muffle furnace and raise the temperature to 800°C at a rate of 10°C / min in an air atmosphere. ℃ roasting for 2 hours to obtain porous flake hexagonal magnesium oxide with a specific surface area of 197m 2 / g, the two-dimensional film size is about 300nm;

[0071] (2) Add 1g of 2-dicyclohexylphosphine-2',4',6'-triisopropylbiphenyl into 30mL of ethanol, ultrasonically disperse for 0.5 hours, and the ultrasonic power is 80kHz to obtain organic carbon, Dispersion of phosphorus source;

[0072] (3) The porous sheet-shaped hexagonal magnesia that 0.5g step (1) obtains is joined in the dispersion liquid that contains organic carbon, phosphorus source that step (2) obtains, with the rot...

Embodiment 3

[0084] This embodiment provides a kind of phosphorus-doped porous graphene, which is prepared through the following steps, such as figure 1 Shown:

[0085] (1) Boil the magnesium oxide powder in water for reflux and keep it for 10 hours, cool and filter it, then dry it at 80°C for 10 hours, then place it in a muffle furnace and raise the temperature to 300°C at a rate of 10°C / min in an air atmosphere. ℃ roasting for 2 hours to obtain porous flake hexagonal magnesium oxide with a specific surface area of 190m 2 / g, the two-dimensional film size is about 200nm;

[0086] (2) Add 2g of triphenylphosphine into 30mL of ethanol, ultrasonically disperse for 0.5 hours, and the ultrasonic power is 80kHz, to obtain a dispersion containing organic carbon and phosphorus sources;

[0087] (3) The porous flaky hexagonal magnesia that 0.5g step (1) obtains is joined in the dispersion liquid that contains organic carbon, phosphorus source that step (2) obtains, with the rotating speed magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com