High-density air flotation settling basin device

A settling tank and high-density technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, flotation water/sewage treatment, neutralization water/sewage treatment, etc., can solve problems such as unsatisfactory effects, and achieve improved results and improved The effect of removal rate and water content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

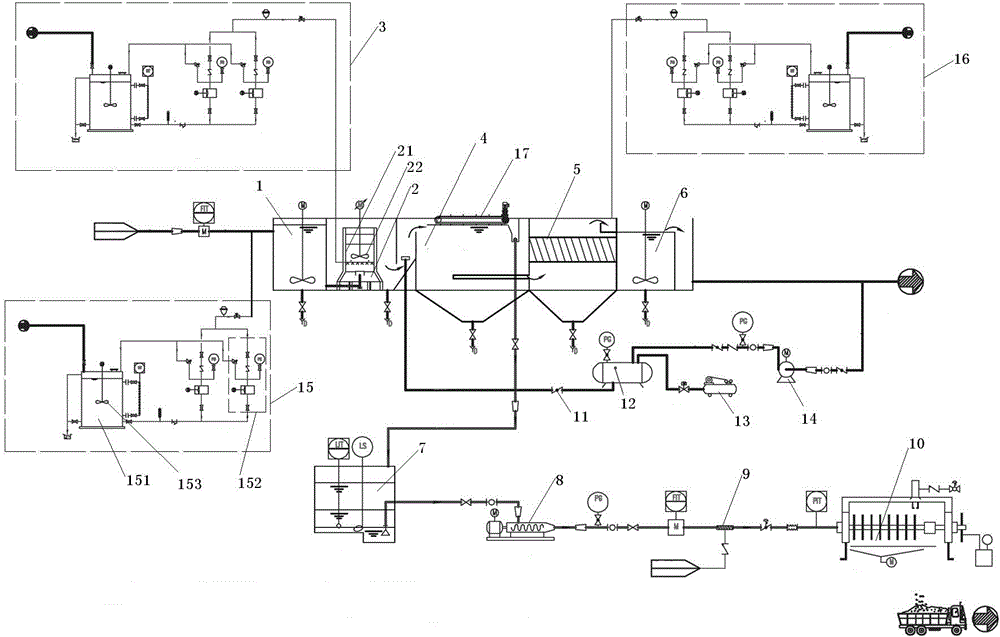

[0013] refer to figure 1 , a high-density air flotation sedimentation tank device, including a coagulation tank 1, the first drug system 3 is connected to the water inlet pipeline of the coagulation tank 1, and the waste water enters the coagulation tank 1, stirred by a fast mixer, and coagulated Coagulation by contact with the agent, adjust the dosage of the agent according to the waste water flow and water quality, and avoid the precipitation of alum flowers. The outlet of the coagulation tank 1 is connected to the bottom of the flocculation reactor 2 through a pipeline. The flocculation reactor 2 is equipped with a lift mixer and a lift cylinder. The reactor consists of two consecutive zones, a fast flocculation zone connected to the mixing zone, and a slow flocculation zone required for alum flower growth. The rapid flocculation is carried out in the lifting cylinder 21 and stirred by the lifting mixer 22 to ensure the rapid flocculation and supply the energy required for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com