Multifunctional wastewater treating agent and application thereof in wastewater treatment process

A sewage treatment agent and sewage treatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of unstable product quality, increased sewage treatment costs, Problems such as poor controllability of dosage, to achieve the effect of diversification of treatment functions, reduction of sewage treatment costs, and good controllability of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

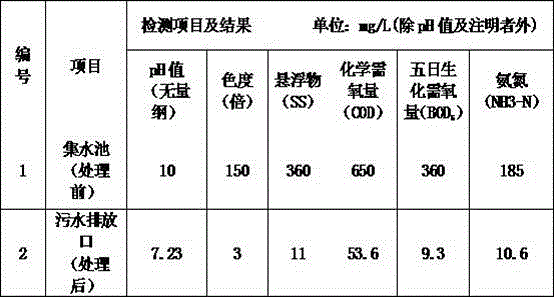

Embodiment 1

[0026] The application of a multifunctional sewage treatment agent in a sewage treatment process comprises the following steps:

[0027] 1) First, concentrate the sewage in the stainless steel bucket;

[0028] 2) Next, add the multifunctional sewage treatment agent to the sewage in the stainless steel bucket, and stir for 10 minutes; the mass ratio of the sewage to the multifunctional sewage treatment agent is 100: 0.1.

[0029] 3) Secondly, stop stirring, stand still, flocculate and settle for 10 minutes;

[0030] 4) Secondly, discharge the upper clear water for recycling;

[0031] 5) Finally, after the sediment is press-filtered, the filter residue is packed, and the sewage enters the stainless steel barrel for recycling.

[0032] This multifunctional sewage treatment agent, by mass 100%, includes:

[0033] Cationic polyacrylamide 2%

[0034] Anionic polyacrylamide 11%

[0035] Non-ionic polyacrylamide 9%

[0036] Polyaluminum Chloride 39%

[0037] Polyferric Sulfate ...

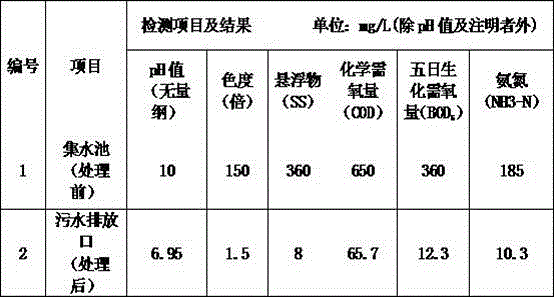

Embodiment 2

[0047] The application of a multifunctional sewage treatment agent in a sewage treatment process comprises the following steps:

[0048] 1) First, concentrate the sewage in the stainless steel bucket;

[0049] 2) Next, add the multifunctional sewage treatment agent to the sewage in the stainless steel bucket and stir for 5 minutes; the mass ratio of the sewage to the multifunctional sewage treatment agent is 100:0.05.

[0050] 3) Secondly, stop stirring, stand still, flocculate and settle for 30 minutes;

[0051] 4) Secondly, discharge the upper clear water for recycling;

[0052] 5) Finally, after the sediment is press-filtered, the filter residue is packed, and the sewage enters the stainless steel barrel for recycling.

[0053] This multifunctional sewage treatment agent, by mass 100%, includes:

[0054] Cationic polyacrylamide 5%

[0055] Anionic polyacrylamide 8%

[0056] Non-ionic polyacrylamide 9%

[0057] Polyaluminum Chloride 41%

[0058] Polyferric Sulfate 6% ...

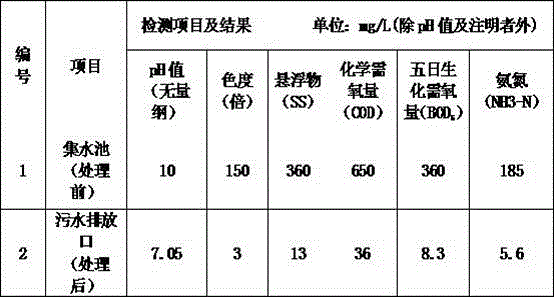

Embodiment 3

[0068] The application of a multifunctional sewage treatment agent in a sewage treatment process comprises the following steps:

[0069] 1) First, concentrate the sewage in the stainless steel bucket;

[0070] 2) Next, add the multifunctional sewage treatment agent to the sewage in the stainless steel bucket, and stir for 8 minutes; the mass ratio of the sewage to the multifunctional sewage treatment agent is 100:0.08.

[0071] 3) Secondly, stop stirring, stand still, flocculate and settle for 20 minutes;

[0072] 4) Secondly, discharge the upper clear water for recycling;

[0073] 5) Finally, after the sediment is press-filtered, the filter residue is packed, and the sewage enters the stainless steel barrel for recycling.

[0074] This multifunctional sewage treatment agent, by mass 100%, includes:

[0075] Cationic polyacrylamide 3%

[0076] Anionic polyacrylamide 9%

[0077] Non-ionic polyacrylamide 8%

[0078] Polyaluminum Chloride 45%

[0079] Polyferric Sulfate 6%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com